Cleaning of the sensor – M&C TechGroup KS 2.Ex Operator's manual User Manual

Page 13

13

Gas sampling and conditioning technology

5-5.3 ME

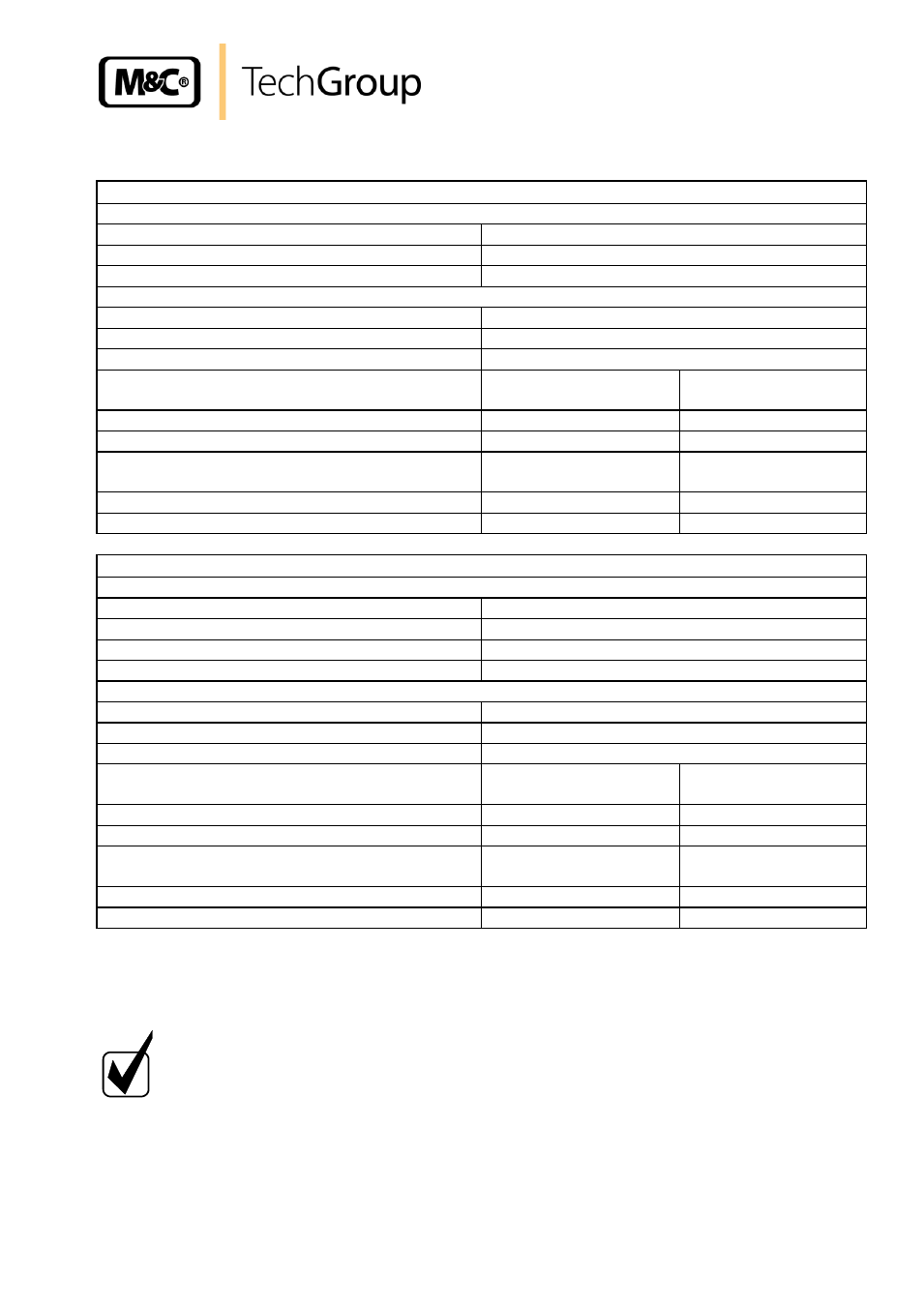

Technical data for switch amplifiers (techn. data sensor see page 5)

Evaluation for example by section switch amplifier KFA6-SR2-Ex1.W

Nominal revolutions according to DIN 19234 respectively Namur

Voltage U

O

10,6 V

Current I

0

19 mA

Power consumption P

0

51 mW

Data according to certificate of conformity for KS2.Ex

Voltage max. U

O

13,5V

Current max. I

K

31mA

Power consumption P

max

125mW

Permissible connection data

Class

EEx ia

IIB

EEx ia

IIC

Outer capacity max.

929nF

230nF

Outer inductivity max.

5mH

3mH

Permissible connection data

Class

EEx ib

IIB

EEx ib

IIC

Outer capacity max.

2929nF

609nF

Outer inductivity max.

115mH

31mH

Evaluation by section switch amplifier WE77/Ex1

Nominal revolutions according to DIN 19234 respectively Namur

No-load voltage U

AO

approx. 8V DC

Locked motor current J

AK

approx. 8mA

Forward break-over point J

S

1,2mA - 2,1mA

Switching hysteresis J

H

approx. 0,2mA

Data according to certificate of conformity

Voltage max. U

O

13,5V

Current max. I

K

31mA

Power consumption P

max

125mW

Permissible connection data

Class

EEx ia

IIB

EEx ia

IIC

Outer capacity max.

929nF

230nF

Outer inductivity max.

5mH

3mH

Permissible connection data

Class

EEx ib

IIB

EEx ib

IIC

Outer capacity max.

2929nF

609nF

Outer inductivity max.

115mH

31mH

10

CLEANING OF THE SENSOR

N O T E !

The plastic housing of the sensor has to be cleaned with a moist cloth.