Zebra Technologies 160S User Manual

Page 78

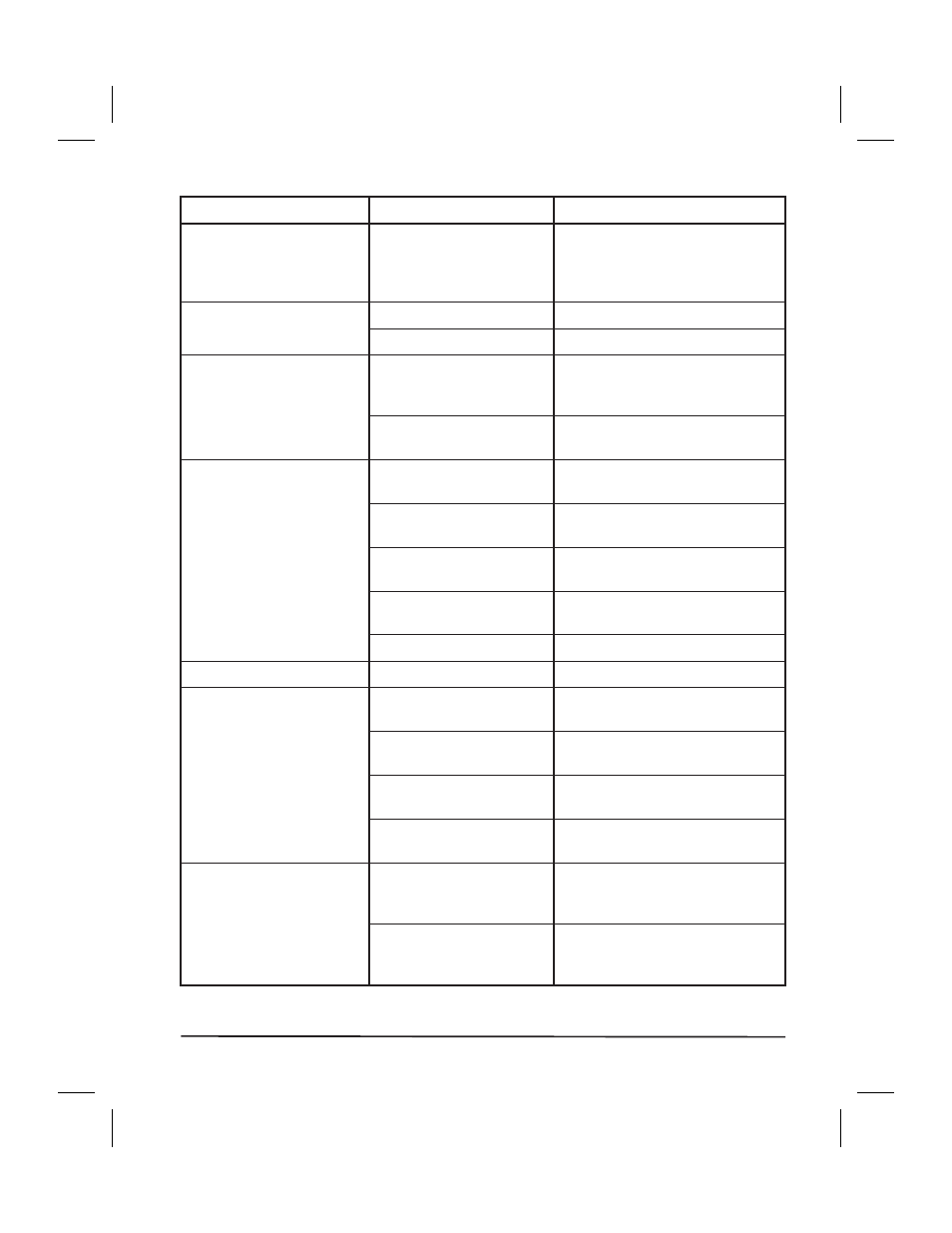

SYMPTOM

DIAGNOSIS

ACTION

Truncated print, no print, or

FEED button operates incor-

rectly while using non-

continuous media.

Media or ribbon improperly

loaded.

See Media Loading and Ribbon Load-

ing instructions in Installation.

Long tracks of missing print on

several labels.

Wrinkled ribbon.

See Wrinkled Ribbon in this table.

Print element damaged.

Call a service technician.

In Peel-Off Mode, skewed or

stuck labels.

Glue material from back of la-

bels causing media movement

problems.

Refer to Preventive Maintenance and

perform maintenance and cleaning of

the printer.

Media and backing not prop-

erly aligned in printer.

Refer to Installation.

Wrinkled ribbon.

Ribbon fed through machine

incorrectly.

See Ribbon Loading in Installation.

Incorrect Darkness setting.

Set to the lowest value needed for good

print quality.

Incorrect printhead

position or pressure.

Adjust toggle pressure and/or position.

Media not feeding properly; it

is walking from side to side.

Make sure the media is snug by adjust-

ing the media guides.

Continuing symptoms.

Call a service technician.

Continued wrinkled ribbon.

Strip plate needs adjusting.

Call a service technician.

Misregistration and misprint of

1 to 3 labels.

Media was pulled when motor

was not moving.

Enter Calibrate Mode and recalibrate.

Incorrect Media Sensor posi-

tion.

See the media sensor position adjust-

ments in Adjustments.

Media or ribbon improperly

loaded.

See Media and Ribbon Loading in In-

stallation.

Incorrect Media Sensor

position or sensitivity.

See Configuration and Calibration.

Changes in parameter settings

did not take effect.

Parameters are set or saved in-

correctly.

Reload the factory defaults. Refer to

Operation and calibrate the printer.

Then, cycle the power ON/OFF Switch.

If problem continues, there

may be a problem on the main

logic board.

Call a service technician.

Zebra S-Series User’s Guide

8-3

77