Troubleshooting — components, Troubleshooting — procedure, Gold cgi gas-fired water boiler — boiler manual – Weil-McLain GOLD CGI 550-110-710/0107 User Manual

Page 48: Air pressure switch, Check the following, Before troubleshooting

GOLD CGi Gas-Fired Water Boiler — Boiler Manual

48

Part Number 550-110-710/0107

Troubleshooting — components

11b

Troubleshooting — procedure

11a

Air pressure switch

Make sure boiler water temperature is 100 °F or cooler

before starting procedure to obtain appropriate read-

ings.

The boiler will not operate correctly unless pressure

switch hoses are correctly located. The red hose con-

nects from the right side (negative) hose barb to the

flue collector. The white hose connects from the left

side (positive) hose barb of the switch to the connector

box (between flue collector and inducer) as shown in

Figure 36

, page 49.

Check pressure switch setting

1. See

Figure 36

,

page 49, and

Table 9

.

. Remove both air pressure switch hoses from air pressure switch.

3. Install tees and tubing as shown in

Figure 36

, page 49, to inclined manom-

eter.

4. Turn off gas valve and set thermostat to call for heat. Inducer will run but burn-

ers will not ignite.

5. Check for 4 VAC between both air pressure switch terminals.

Troubleshooting air pressure reading

1. If manometer reading is lower than the setpoint of the switch (see

Table 9

)

— check for possible causes:

• blockage in hoses

• obstruction in inducer housing outlet

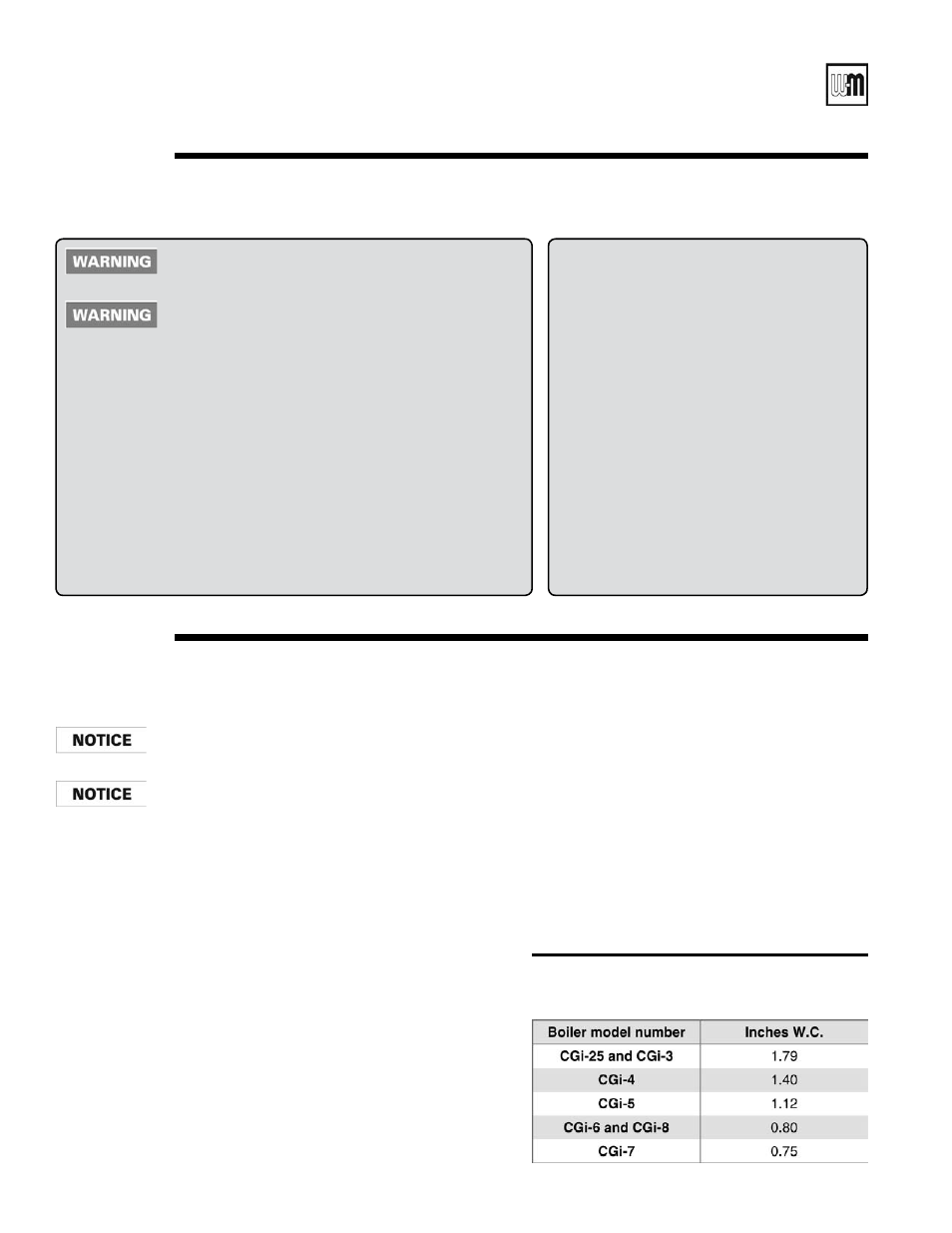

Table 9

Pressure switch setpoint (for elevations

above 2,000 ft, contact your local Weil-

McLain sales office for details.)

• loose inducer wheel on motor shaft

• inducer motor not in proper rpm

• inducer back plate not sealed properly

• blockage in block assembly

6. If manometer reading is above the setpoint of the switch

(see

Table 9

), but there is not 4 VAC between both air

pressure switch terminals — replace air pressure switch.

Return to normal operation

When pressure reading is correct and air pressure switch is

operating properly — remove tees and reinstall hoses to air

pressure switch.

Check the following:

1. Wire connectors to control module are se-

curely plugged in at module and originating

control.

. Air pressure switch hoses are properly and

securely plugged in and are not damaged.

3. Gas pressures:

a. With boiler off — 13” w.c. maximum

natural or propane gas pressure up-

stream of gas valve.

b. With boiler on:

• 5” w.c. minimum natural gas

pressure or 11” w.c. propane gas

pressure upstream of gas valve.

• 3 ½” w.c. minimum natural gas

pressure or 10” w.c. propane gas

pressure downstream of gas valve

— Can be adjusted by regulator

on gas valve.

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and danger-

ous operation.

Never jumper (bypass) rollout thermal fuse element

or any other device except for momentary testing as

outlined in

Troubleshooting Charts

. Severe personal

injury, death or substantial property damage can re-

sult.

Before troubleshooting:

1. Have the following items:

a. Voltmeter that can check 10 VAC and 4 VAC.

b. Microammeter with a minimum scale range of 0-5.

c. Continuity checker.

d. U-tube manometer.

. Check for 10 VAC (minimum 10 VAC to maximum 13 VAC) to

boiler.

3. Make sure thermostat is calling for heat and contacts (including appro-

priate zone controls) are closed. Check for 4 VAC between thermostat

wire nuts and ground.