4 recommended vent/air intake terminal position – Rinnai E75CN User Manual

Page 30

Installation & Servicing Instructions Rinnai E-Series

30

6.7.4

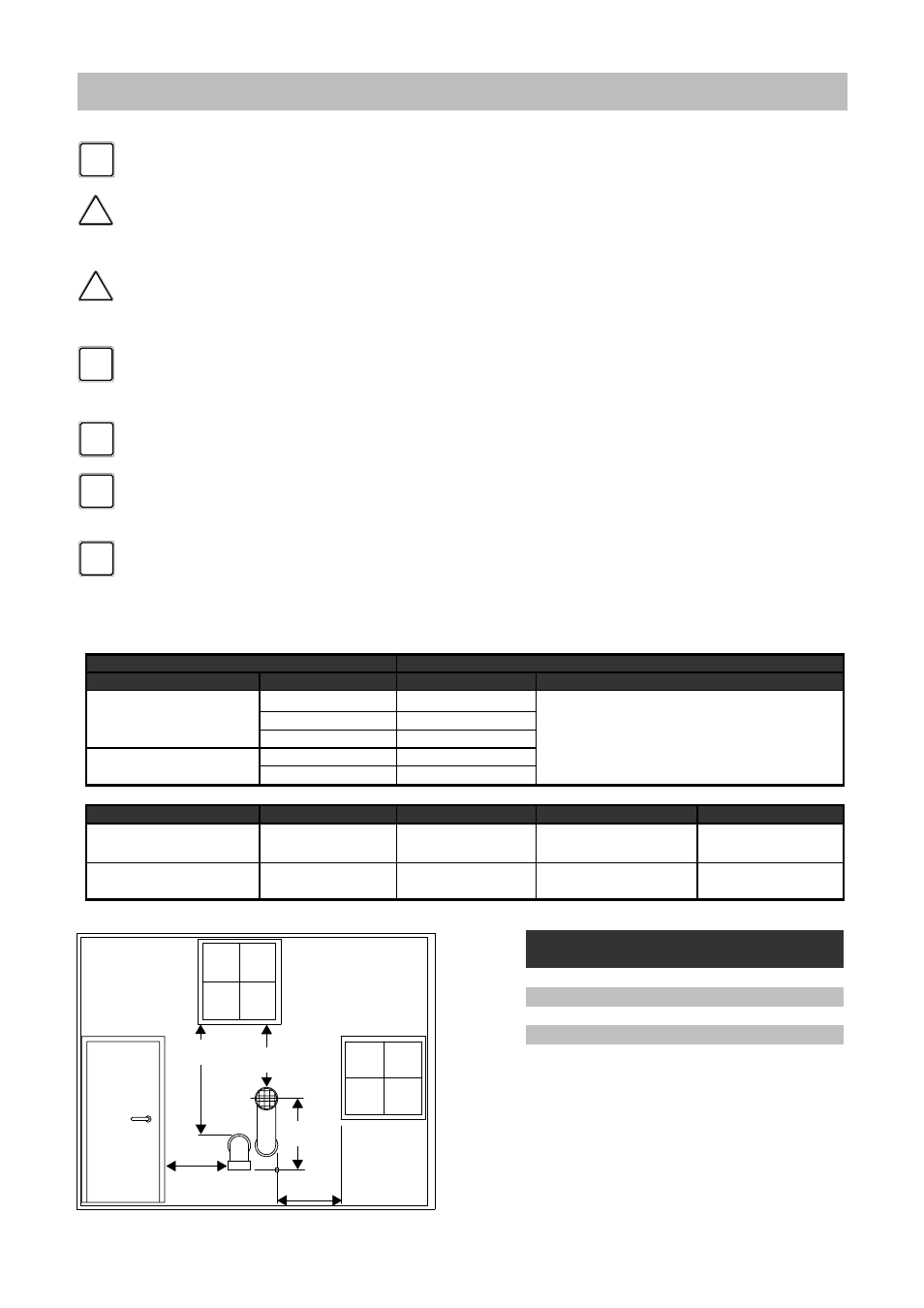

Recommended vent/air intake terminal position

Terminals should be positioned as to avoid products of combustion entering

openings into buildings or other vents.

Maintain 12” of clearance above the highest anticipated snow level or grade

or, whichever is greater. Please refer to your local codes for the snow level in

your area.

The termination shall be at least 4 feet (1,220 mm) for the US and 6 feet (1,830

mm) for Canada distance from electric meters, gas meters, regulators and

relief equipment. (for room air application only)

Horizontal vent systems should always be installed sloping towards the

boiler (min. 21 mm/m, 1/4 “/ feet), in order to avoid condensate retaining in

the vent system. With the condensate running back to the boiler the risk of

ice forming at the terminal is reduced.

The whole route of the vent system must be installed upwards, never

downwards, completely nor partly.

Place pipe supports every 4 feet (1219 mm) of horizontal run, beginning with

the support near the boiler to prevent movement in fittings and allow boiler

to be free from any strain or weight on boiler or fittings.

The terminal should be located where dispersal of combustion products is

not impeded and with due regard for the damage or discolouration that might

occur to building products in the vicinity (see fig 14 and 15).

NOTICE

i

!

CAUTION

!

CAUTION

NOTICE

i

NOTICE

i

NOTICE

i

NOTICE

i

12" (300 mm)

minimum

12" (300 mm)

minimum

12" (300 mm)

minimum

INTAKE

EXHAUST

12" (300 mm)

minimum

12" (300 mm)

minimum

Terminal positions PVC figure 15

Approval codes for installation of venting system

table 7

Equivalent friction loss of PVC/CPVC table 8

Item Description

Flue Material

United States

PVC Schedule 40

ANSI/ASTM D1785

PVC - DWV

ANSI/ASTM D2665

CPVC Schedule 40 ANSI/ASTM F441

PVC

ANSI/ASTM D2564

CPVC

ANSI/ASTM F493

Item Description

Flue Material

Manufacturer

US/CAN

Flue system

Plastic Vent and/or air

pipes and fittings

PPS

Ubbink

Rolux Condensing

Vent System

Approval Codes for Installation

Plastic Vent and/or air

pipes and fittings

Plastic Pipe cement and

primer

Saf-T Vent SC

Saf-T Vent EZ Seal

Stainless steel vent

systems

AL29-4C

Heat Fab

concentric

UL1738 twin pipe

Fittings or Piping Equivalent

feet

m

45 degree elbow

3

0.91

90 degree elbow

6

1.83

plastic pipe per foot

1

0.30

concentric vent kit

3

0.91