Rinnai E75CN User Manual

Page 24

Installation & Servicing Instructions Rinnai E-Series

24

6.5

Hot water supply

Connection of the drinking water installation should be performed according to the

national secondary drinking water regulations.

Do NOT use toxic chemicals, such as are used for boiler treatment in potable

water heating systems used for space heating.

The sanitary water pipes can be connected to the installation by use of adapter

fittings. The cold water inlet on the Combi boilers must be equiped with the following

components (counted in the water flow direction):

Flow regulator valve (supplied), Safety group, Expansion vessel 87 PSI / 6bar (potable

water, blue).

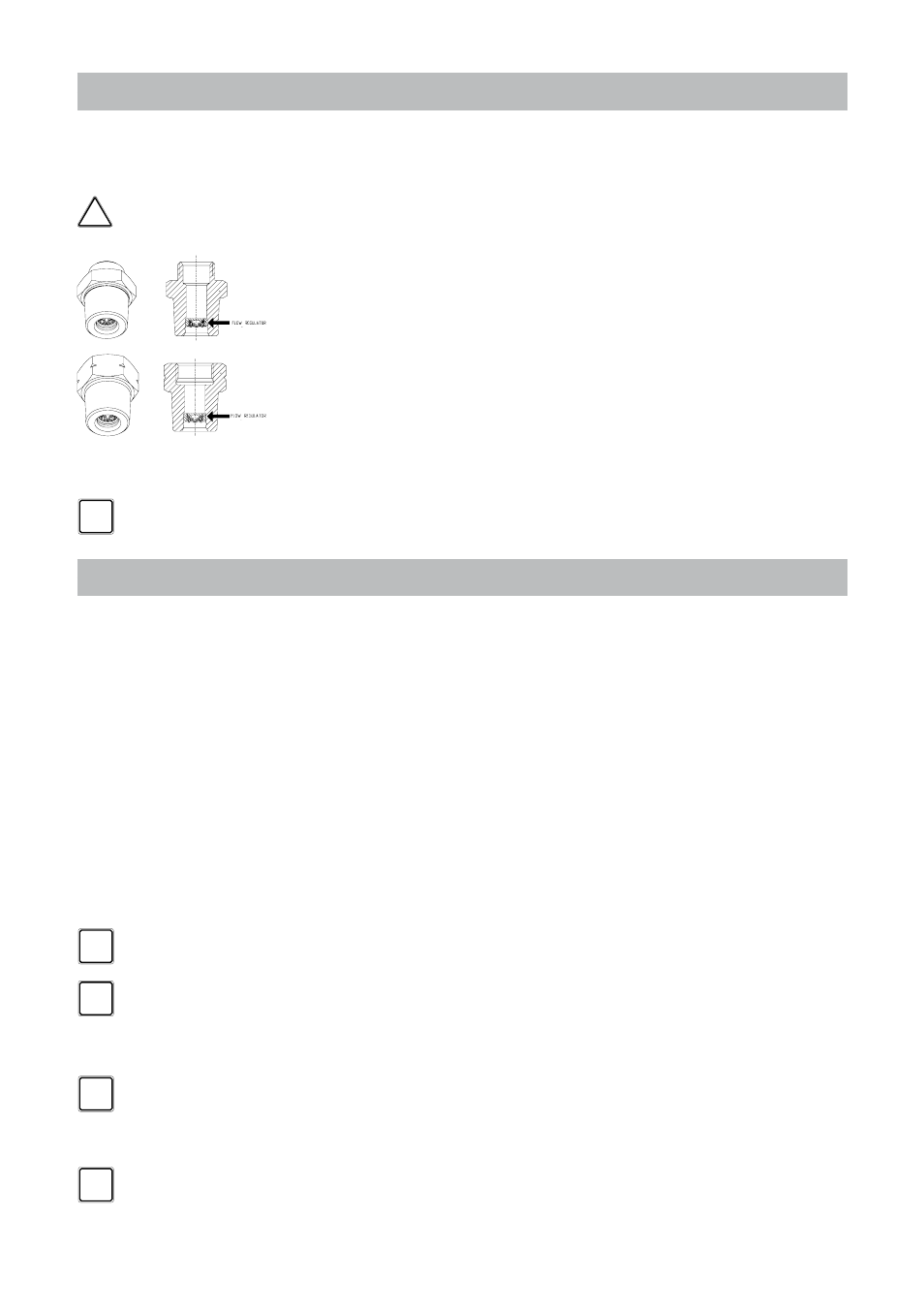

The 3/4" NPT adapter fitting with flow reducing valve must be fitted in the cold water

connection.

A flow regulator valve is supplied with the boiler in a 3/4"NPT adapter fitting. The

flow regulator valve ensures that a quantity of water is supplied which has a outlet

temperature of 120°F (assuming a cold water temperature of 45°F). The quantity of

water is virtually unaffected by the water pressure.

When there is a water pressure lower than 22PSI / 1.5 bar it is advisable to

remove the inside mechanism of the flow reducing valve.

6.6 Condensate drain pipe

This boiler produces condensate. Condensate must be drained otherwise the boiler

will not function and can cause property damage.

The condensation drain pipe should be connected to a drain in the building by means

of an open connection. By this means the possibility of drain gases effecting the boiler

is prevented. The drain connection should have a minimum diameter of 1.3" / 32mm.

Install the condensation drain pipe according to the applicable rules and

regulations.

If the condensate outlet of the boiler is lower than the public sewage system a

condensate pump must be used.

The condensate produced by the boiler has a pH value between 3 and 4.

Install a neutralization unit if required by the local code. It is recommended, but not

required to install a condensate neutralizer.

Do not drain the condensation water to the external rain gutter because of

the danger of freezing and blockage of the drain.

Before putting the boiler into operation fill the condensate trap with 1.27

cups / 300 ml of water. If the boiler will be installed in a high temperature

installation such as baseboard, then fill the condensate trap with mineral oil

instead of water.

Use materials approved by the authority having jurisdiction. In absence of such

authority, PVC and CPVC pipe must comply with ASTM D1785, F441 or D2665.

Cement and primer must comply with ASTM D2564 or F493.

For Canada, use CSA or ULC certified PVC or CPVC pipe, fittings and cement.

Periodic cleaning of the condensate disposal system must be carried out. See

the Rinnai Boiler Application Manual for further information and for a piping

diagram for the condensate.

NOTICE

i

NOTICE

i

NOTICE

i

NOTICE

i

!

DANGER

NOTICE

i