Installation, Venting introduction, Unit assembly prior to installation – Regency P40 User Manual

Page 12: Vent restrictor position, Inst alla tion

Regency

®

P40-1 Direct Vent Gas Fireplace

12

INST

ALLA

TION

INSTALLATION

VENTING INTRODUCTION

The P40 uses the "balanced fl ue" technology Co Axial system. The

inner liner vents products of combustion to the outside while the outer

liner draws outside combustion air into the combustion chamber thereby

eliminating the need to use heated room air for combustion and losing

warm room air up the chimney.

Note: These fl ue pipes must not be connected to any other

appliance.

The gas appliance and vent system must be vented directly to the outside

of the building, and never be attached to a chimney serving a separate solid

fuel or gas burning appliance. Each direct vent gas appliance must use it's

own separate vent system. Common vent systems are prohibited.

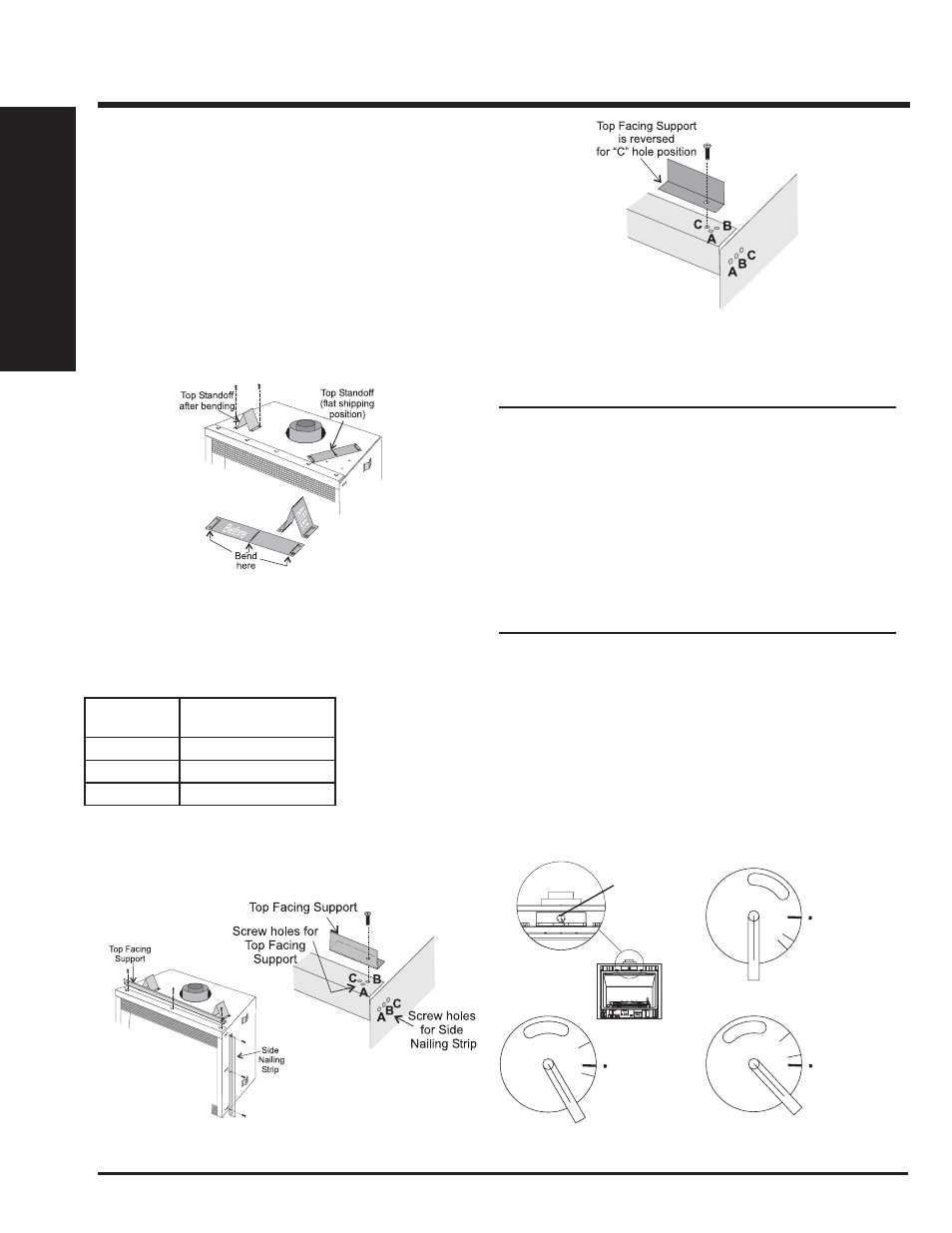

* For "C" screw position the top facing support is reversed.

Note: For screw position C with a facing material depth of 1-1/4"

(32mm), the top facing support must be reversed.

UNIT ASSEMBLY PRIOR TO

INSTALLATION

NOTE: The Top Facing Support, the Side Nailing Strips and the 2 Top

Standoffs must be correctly positioned and attached before unit is

slipped into position.

TOP STANDOFF ASSEMBLY

The top standoffs are shipped in a fl at position and must be folded into

shape and attached.

1) Remove the standoffs from top of the fi replace.

2) Take each standoff and bend into the correct shape. Bend up at the

bend lines until the screw holes in the standoff and the pre-punched

screw holes on the fi replace top line up.

3) Attach the standoff securely to the top with 2 screws per standoff

(on opposite corners).

TOP FACING SUPPORT AND SIDE NAILING STRIPS

Determine the total thickness of facing material to allow the fi nished surface

to be fl ush with the front of the unit. Total facing thickness can vary from

1/2" (13mm) to 1-1/4" (32mm) thick.

The Top Facing Support & Side Nailing Strips can be mounted in 3 different

positions depending on the thickness of the facing material.

1) Mount Top Facing Support using the 3 supplied screws into the three

pre-punched screw holes on the top front of the unit. Use hole posi-

tions A, B, or C depending on your facing depth.

2) Use the same screw hole position for the Side Nailing Strips as was

used for the Top Facing Support. Attach each side nailing strip using

3 screws.

Note: When installing side strips into position C, the side strips are not

reserved.

Screw

Position

Facing Material Depth

A

1/2" / 13mm

B

7/8" / 22mm

C*

1-1/4" / 32mm

VENT RESTRICTOR POSITION

Vent restriction is required for certain venting installations, see the diagrams

in the "Venting Arrangements" section to determine if they are required

for your installation.

To set the Vent restriction as indicated in the diagrams in the "Venting

Arrangements" section, refer to the instructions below;

1) Remove the top louver if installed.

2) Loosen the screw on the vent restrictor indicating plate.

3) Rotate the vent restrictor adjustment rod counter clockwise to line

up the slot on the indicating plate with the point on the air box to the

required setting.

4) Tighten screw to lock position.

Vent Restrictor setting at Set 2

Point on AirBox

Screw

Factory Set Vent Restrictor Setting

(no adjustment required)

Point on AirBox

Vent Restrictor setting at Set 1

Point on AirBox