Fuji Bikes FRENIC 5000G11S/P11S User Manual

Page 62

5-15

Holding time

Time

Forward rotation

Starting frequency

Stopping frequency

Output frequency

The starting frequency can be set to reserve the torque at

startup and can be sustained until the magnetic flux of the

motor is being established.

Frequency: This function sets the frequency at startup.

Setting range: 0.1 to 60Hz

Holding time: This function sets the holding time

during which the start frequency is sustained at startup.

Set values: 0.1 to 10.0 seconds

∗

The holding time does not apply at the time of switching

between forward and reverse.

∗

The holding time is not included in the acceleration time.

∗

The holding time also applies when pattern operation

(C21) is selected. The holding time is included in the

timer value.

This function sets the frequency at stop.

Setting range: 0.0 to 60.0Hz

The operation does not start when the starting frequency

is less than the stopping frequency or when the setting

frequency is less than the stopping frequency.

This function adjusts the carrier frequency, correct

adjustment of which prevents resonance with the

machine system, reduces motor and inverter noise, and

also reduces leakage current from output circuit wiring.

Nominal applied motor

Setting range

75HP or less

0.75 to 15kHz

G11

100HP or more

0.75 to 10kHz

30HP or less

0.75 to 15kHz

40HP to 100HP

0.75 to 10kHz

P11

125HP or more

0.75 to 6kHz

Carrier frequency

Low High

Motor noise

High Low

Output current waveform

Bad Good

Leakage current

Small amount Large amount

Noise occurrence

Extremely low High

The tone of motor noise can be altered when the carrier

frequency is 7kHz or lower. Use this function as

required.

Setting range: 0 , 1, 2 , 3

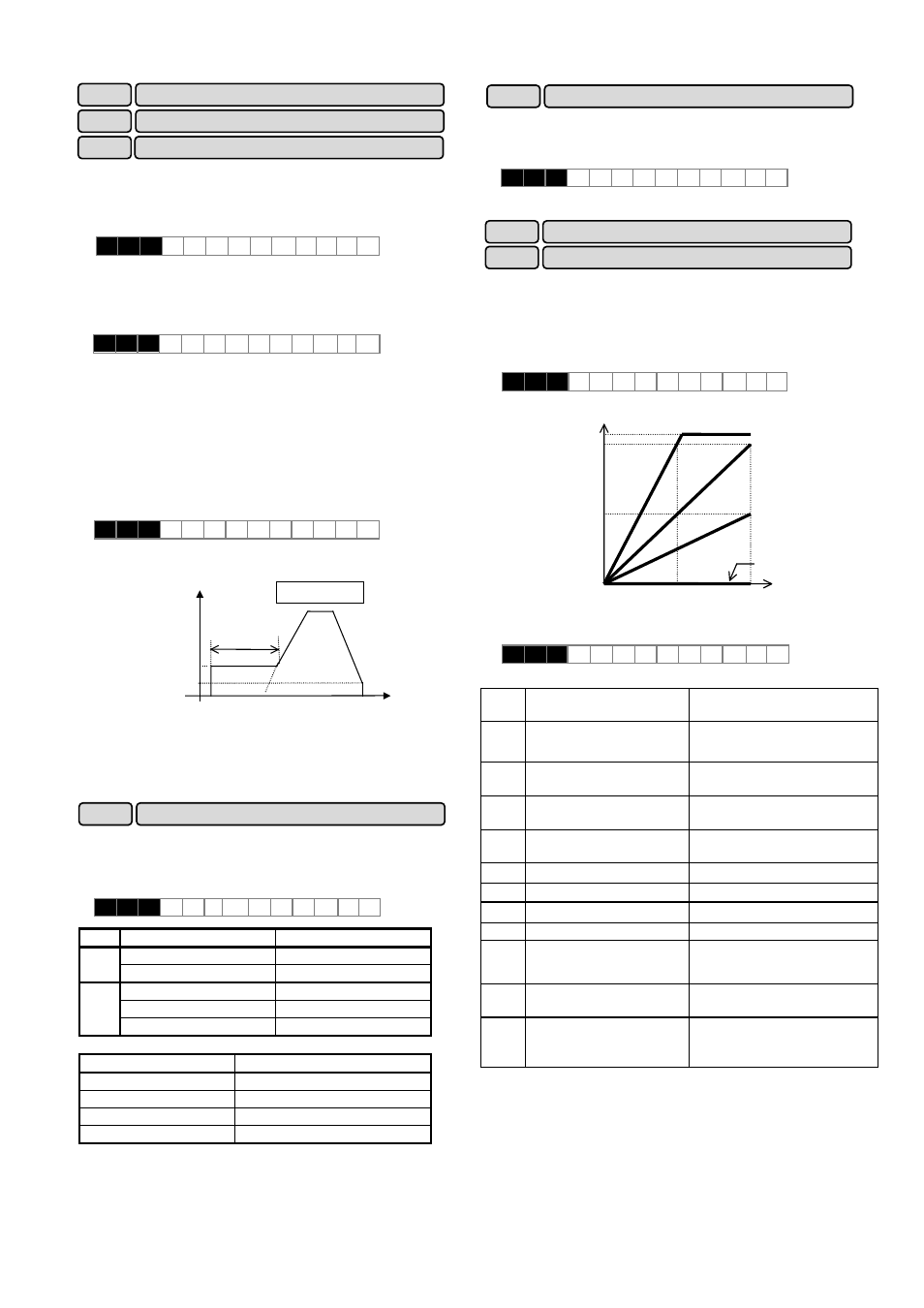

Monitor data (e.g.,output frequency, output current) can

be output to terminal FMA as a DC voltage. The amplitude

of the output can also be adjusted.

This function adjusts the voltage value of the monitor

item selected in F31 when the monitor amount is 100%.

A value from 0 to 200 (%) can be set in 1% steps.

Setting range: 0 to 200%

This function selects the monitor item to be output to

terminal FMA.

Set

value

Monitor item

Definition of 100% monitor amount

0

Output frequency 1

(before slip compensation)

Maximum output frequency

1

Output frequency 2

(after slip compensation)

Maximum output frequency

2 Output

current

Rated output current of

inverter x 2

3

Output voltage

230V series: 250V

460V series: 500V

4

Output torque

Rated torque of motor x 2

5

Load rate

Rated load of motor x 2

6 Power

consumption Rated

output of inverter x 2

7

PID feedback amount

Feedback amount of 100%

8 PG feedback amount

(only when option is installed)

Synchronous speed at

maximum frequency

9

DC link circuit voltage

230V series: 500V

460V series: 1,000V

10 Universal

AO

0 to 10V output through

communication and not related to

inverter operation.

※

The power consumption shows "0" during regenerative load.

F30:200%

Higher than 10V

F30:0%

F30:50%

5V

10V

F30:100%

100%

50%

F

M

A terminal

output

voltage

F23

F24

Starting frequency (frequency)

Start frequency (Holding time)

F25

Stop frequency

F30

FMA (voltage adjust)

FMA (function)

F31

F26

Motor sound (carrier frequency)

F27

Motor sound (sound tone)

Notes:

1. Reducing the set value adversely affects the output

current waveform (i.e., higher harmonics), increases motor

loss, and raises motor temperature. For example, at

0.75kHz, reduce the motor torque by about15%.

2 Increasing the set value increases inverter loss and raises

inverter temperature.

F 2 3

S T A R T

H z

F 2 4

H O L D I N G t

F 2 5

S

T

O

P H z

F 2 6

M T R S O U N D

F 2 7

M T R

T O N E

F 3 0

F M A

V - A D J

F 3 1

F M A

F U N C