Installation and connection, 1 operating environment, 2 installation method – Fuji Bikes FRENIC 5000G11S/P11S User Manual

Page 13: 1 2. installation and connection, Warning

2-1

2. Installation and Connection

2-1 Operating Environment

Install this product in a location that meets those conditions listed in Table 2-1-1

Table 2-1-1 Operating environment

Item Specifications

Table 2-1-2 Output current reduction rate

based on altitude

Location Indoor

Altitude Output

current

reduction rate

3300ft (1000m) or lower

1.00

3300-4950ft (1000 to 1500m)

0.97

Ambient

temperature

-10℃(14ºF) to +50℃(122ºF)(For products of

30HP or less, the ventilating covers must be

removed if ambient temperature exceeds

+40℃(104ºF))

4950-6600ft (1500 to 2000m)

0.95

6600-8250ft (2000 to 2500m)

0.91

Relative

humidity

5 to 95% (No condensation)

8250-9900ft (2500 to 3000m)

0.88

Atmosphere

Pollution degree 2

Air pressure

86 to 106 kPa

Vibration

3mm:from 2 to less than 9 Hz, 1m/s

2

:from 9 to

less than 20 Hz, 1m/s

2

:from 20 to less than 55

Hz, 1m/s

2

:from 55 to less than 200 Hz

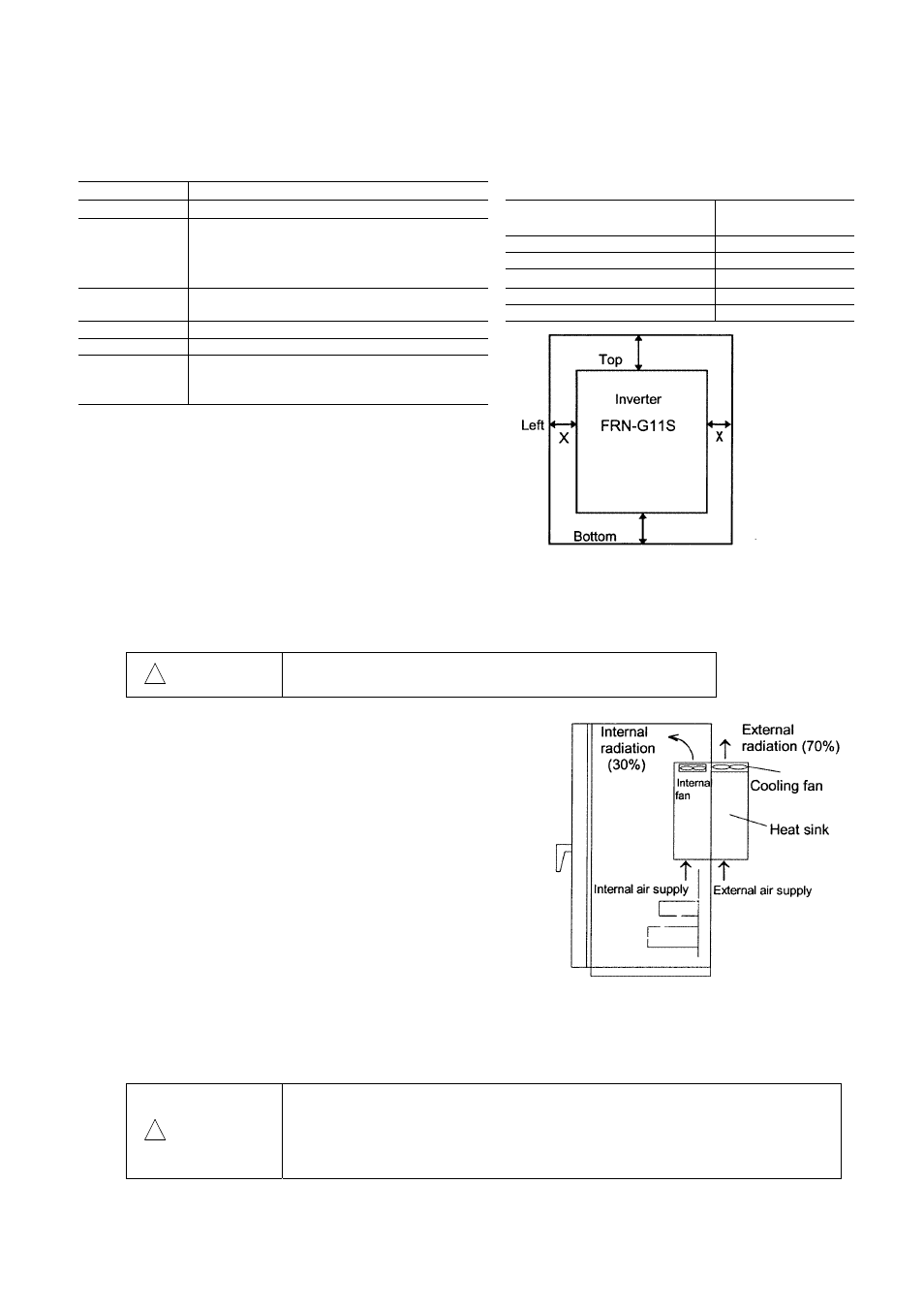

2-2 Installation Method

①

Securely fasten the product in an upright position on a

solid structure such that FRENIC5000G11S is facing

the front.

Do not turn the product upside down or install in a

horizontal position.

②

As heat is generated during inverter operation, the spaces shown in Fig. 2-2-1 are required to ensure

sufficient cooling. As heat radiates upward, do not install the product beneath a device sensitive to heat.

③

As the heat sink may reach a temperature of 90℃(194ºF) during inverter operation, ensure that the

material surrounding the product can withstand this temperature.

!

WARNING

Install this product on nonflammable material such as metal.

④

When installing this product in a control panel, consider

ventilation to prevent ambient temperature of the inverter

from exceeding the specified value. Do not install the

product in an area from which heat cannot be sufficiently

released.

⑤

If two or more inverters must be installed in the same device

or control panel, arrange the units horizontally to minimize

the effect of heat. If two or more inverters must be installed

vertically, place an insulated plate between the inverters to

minimize the effect of heat.

⑥

When shipped from the factory, inverters are internal cooling

type inside panel. An inverter of 30HP or less can be

converted to an external cooling type simply by adding an

optional mounting adapter. An inverter of 40HP or more

can be converted simply by moving mounting adapter.

In an external cooling system, a heat sink radiating about 70% of total inverter heat (total loss) can be

placed outside the device or control panel.

Ensure that heat sink surfaces are kept free of foreign matter (lint, Fig. 2-2-2 External cooling system moist

dust particles etc.).

!

WARNING

・

In case of external cooling system, cover the inverter rear side in order not to

touch the main capacitor and braking resistor. Electric shock may result.

・

Ensure that the inverter and heat sink surfaces are kept free of foreign matter

such as lint, paper dust, small chips of wood or metal, and dust.

Fire or accident may result.

Right

30HP or less:

Gap X can be 0.

(side-by-side

installation)

40HP or more:

Gap X >= 2inch (50mm)

3.9inch(100mm)

3.9inch(100mm)

Fig.2-2-1

Fig.2-2-2