Festo Электромотор MTR-DCI User Manual

Page 19

Contents and general safety instructions

XVII

Festo P.BE-MTR-DCI-DN-EN en 1209a

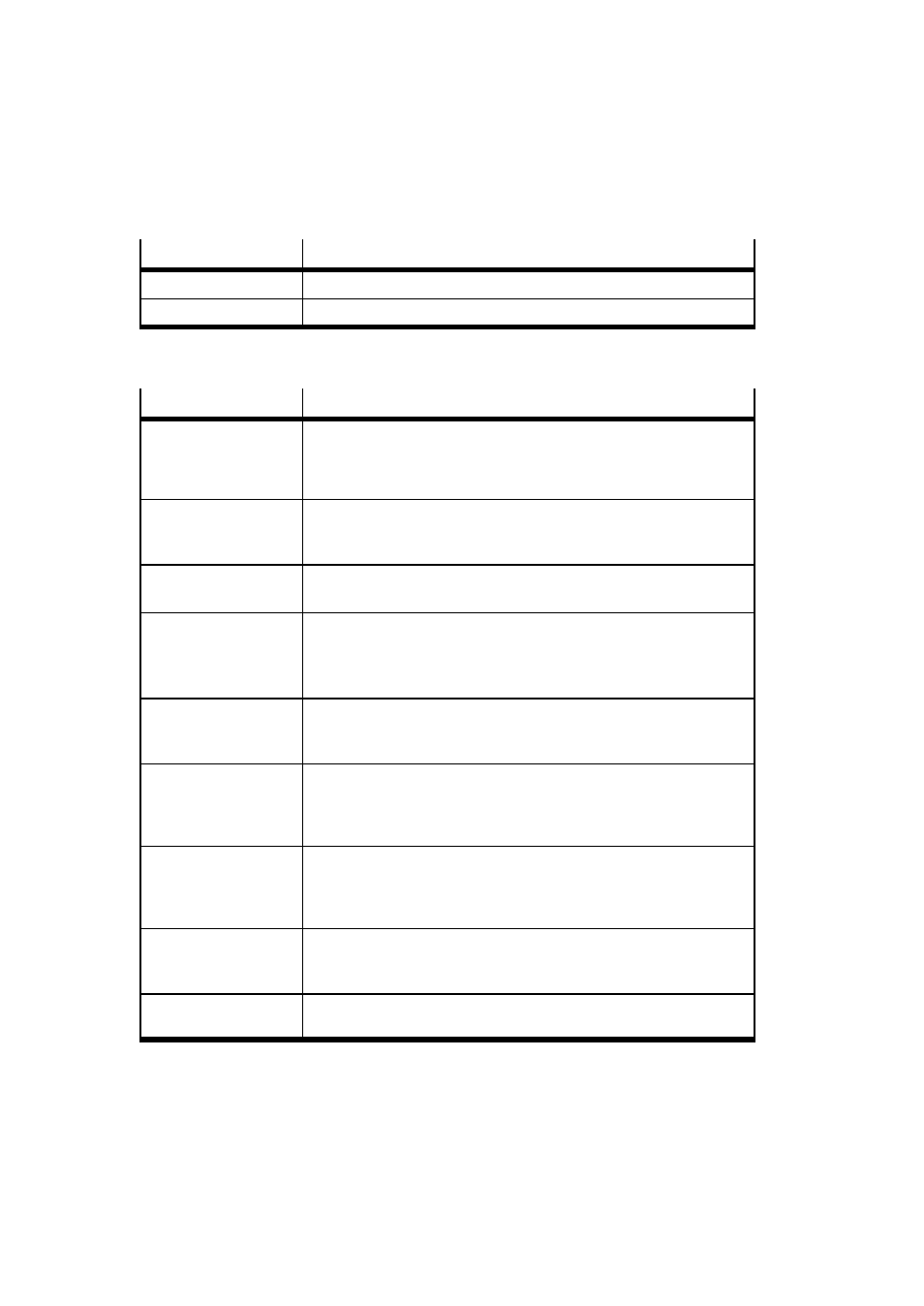

Abbreviation

Meaning

MAC-ID

Media Access Control IDentifier, see “Participant address”

PNU

Parameter number as per FHPP-FPC

Table 0/3: List of abbreviations

Term

Meaning

Axis

Mechanical component of a drive which converts the motor revolutions

into positioning movements of a work load. An axis (e.g. positioning servo

axis DMES-...) enables the work load to be mounted and guided and the

reference switch to be mounted.

Axis zero point (AZ)

Reference point of the software end positions and the project zero posi-

tion PZ. The axis zero point AZ is defined by a preset offset to the refer-

ence point REF.

Drive

Complete actuator, consisting of controller, motor, measuring system

and, if applicable, gear and axis

Operation mode

Is used in the following contexts:

–

Type of access: Record selection, direct task

–

Internal logical state of the controller: Position Profile Mode, Profile

Toque Mode, Homing Mode, ...

Controller

Contains power electronics + controller + positioning control, analyses

sensor signals, calculates movements and forces, and provides the motor

power supply via the power electronics.

Encoder

Optical pulse generator (rotor position transducer on the motor shaft of

the MTR-DCI). The electric signals generated are sent to the controller,

which then calculates the position and speed on the basis of the signals

received.

Festo Configuration Tool

(FCT)

Commissioning software with uniform project and data management for

all supported device types. The special requirements of a device type are

supported with the necessary descriptions and dialogues by means of

plug-ins.

Festo Handling and Posi-

tioning Profile (FHPP)

Uniform field bus data profile for positioning controllers from Festo. Para-

meter values, control bytes, and status bytes required during operation

can be directly read and written via the FHPP object directory.

FHPP standard

Defines the sequence control as per the “Festo Handling und Positioning

Profile”