Festo Линейный привод с датчиком перемещения DFPI User Manual

Linear drive dfpi-...-...-nd2p-c1v-...-a

Linear drive

DFPI-...-...-ND2P-C1V-...-A

Festo AG & Co. KG

Postfach

73726 Esslingen

Germany

+49 711 347-0

www.festo.com

(en)

Operating instructions

8029184

1309a

[8029186]

Original: de

Linear drive DFPI-...-...-ND2P-C1V-...-A

English

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

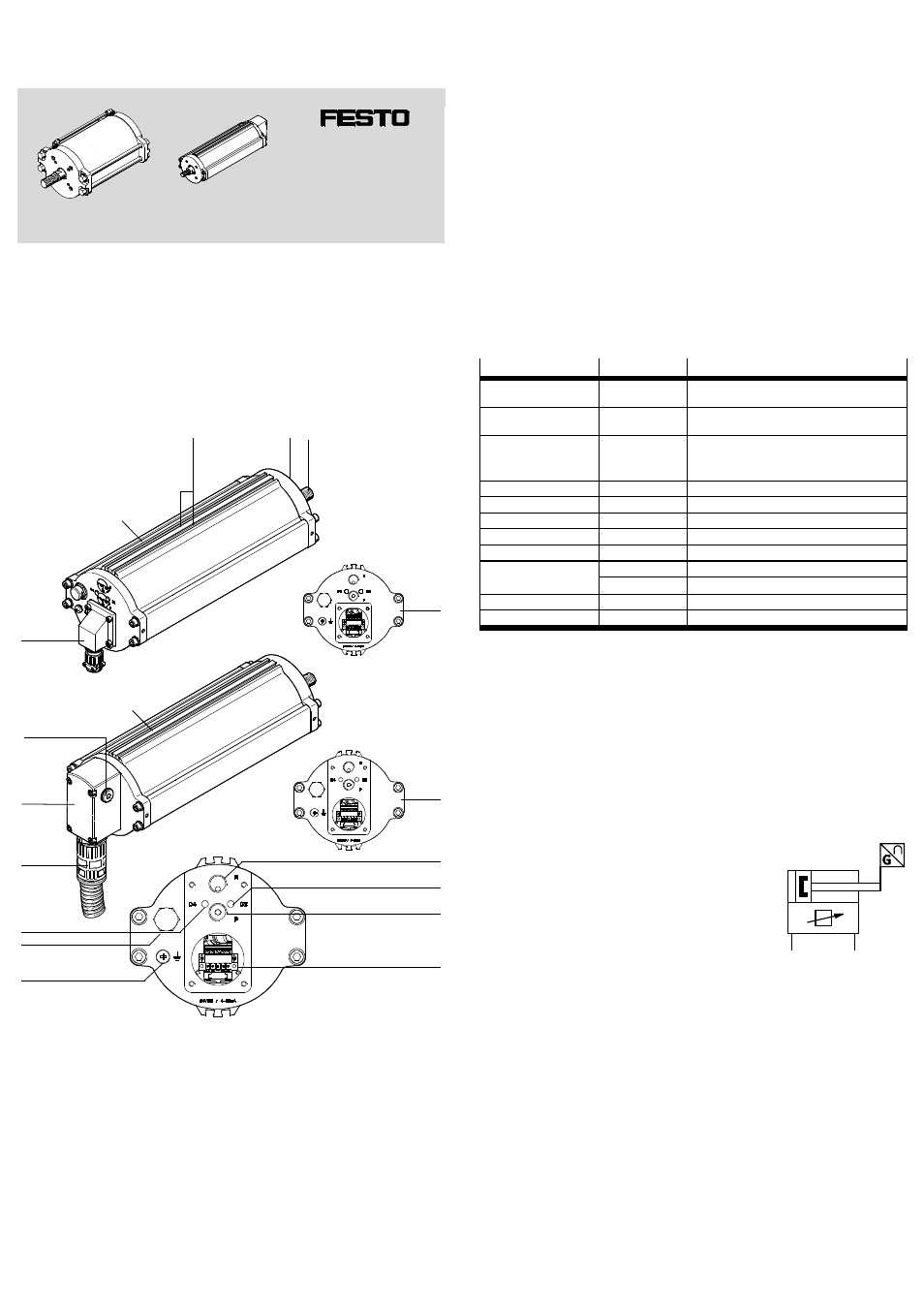

Operating elements and connections using as an example the DFPI-100-...

2

1

4

3

9

aJ

aA

aB

DFPI-...-...-ND2P-C1V-A

DFPI-...-...-ND2P-C1V-P-A

4

5

6

7

8

aC

aD

aE

1 Slot for proximity sensor

2 Mounting thread (reverse side,

Fig. 4)

3 Piston rod with mounting thread

for coupling and spanner flat for

counter holding

4 Representation without flange

receptacle

5 Pneumatic interface

*)

– channel R

(exhaust)

6 Flow control screw D2

7 Pneumatic interface

*)

– channel P

(compressed air supply)

8 Electrical connection behind the

flange receptacle

9 Earth terminal; position dependent

on piston diameter

aJ Pressure compensation element

aA Flow control screw D4

aB Optional: connecting cable with

protective conduit (accessories)

aC Flange receptacle – here

DFPI-...-...-ND2P-C1V-P-A

aD Plug screw (from factory) or filter

nipple or silencer (accessories)

aE Flange receptacle – here

DFPI-...-...-ND2P-C1V-A

*)

Pneumatic connection

Fig. 11

Fig. 1

2

Design

The DFPI-...-...-ND2P-C1V-…-A is an electro-pneumatic linear drive consisting of:

– a double-acting pneumatic cylinder with

– integrated displacement encoder (potentiometer) for determining the actual

position

– integrated valve manifold with directional control valves for controlling the pis-

ton rod

– integrated positioner for position control.

If necessary, proximity sensors can be installed in the available slots (

Fig. 1

1 )

in order to provide binary interrogation of positions.

A pressure compensation element (

Fig. 1

aJ ) prevents the formation of con-

densate inside the housing in the event of temperature fluctuations, thus protect-

ing the internal electronics.

For DFPI-...-...-ND2P-C1V-A the pneumatic connections are freely accessible (pneumatic

connection G¼). The electrical connections are protected by a flange receptacle.

For DFPI-...-...-ND2P-C1V-P-A the electrical and pneumatic connections are protec-

ted against external mechanical influences by a rugged flange receptacle. The

flange receptacle provides push-in connectors for the pneumatic system and a G¼

exhaust port for venting on site.

The product is available in various designs. These operating instructions describe

the following product variants:

Features

Type codes

Description

Type

DFPI–

Double-acting pneumatic drive for process auto-

mation with integrated displacement encoder

Size of valve actuator

100–, 125– , 160–,

200–, 250–, 320–

Piston diameter can be selected in steps, spe-

cifications in [mm]

Stroke

...–

Stroke length freely selectable in the range from

40 to 990;

(40 ... 990)

Specifications in [mm]

Cushioning

N

No cushioning

Displacement encoder

D2

Analogue displacement encoder

Method of measurement

P–

Potentiometer

Regulation

C1

Controller 1

Directional control valve

V–

Integrated

Connection type

Not specified

Unprotected pneumatic connections

P

Protected pneumatic connections

Feedback signal

A

Analogue feedback signal, actual value

Safety position

Not specified

Piston rod advancing

Fig. 2

Type code (e.g. DFPI-100-200-ND2P-C1V-P-A)

The following characteristics of the linear drive are dependent on the piston

diameter, and may differ from the representation in Fig. 1:

– Position of the earth terminal (

identification on product)

– Shape of the cylinder barrel

– Shape of the flange receptacle.

In addition, for linear drives with a piston diameter ≥ 200 mm the compressed air

supplied from one side is fed via an unprotected line parallel to the cylinder barrel.

Tie rod screws are used to mount the cylinder end cap. For linear drives with a

piston diameter ≤ 200 mm the compressed air is fed internally. The cylinder end

caps are screwed to the housing.

3

Function

The compressed air applied at connection P

is directed by the integrated valve manifold

alternately to the two piston chambers of

the cylinder – depending on the setpoint po-

sition that is specified. This causes the pis-

ton rod connected to the piston to move

backwards and forwards.

Fig. 3

The maximum possible venting of the two cylinder chambers can be set independ-

ently of each other using flow control screws D2 and D4. D2 controls the venting

flow when the piston rod advances. D4 controls the venting flow when the piston

rod retracts. This can be used to influence the maximum travel speed of the linear

drive in the range from 0 ... 100 %. In the factory setting, the flow control screws

are completely open. In the DFPI-...-...-ND2P-C1V-A they are protected against

contamination by rubber plugs, and in the DFPI-...-...-ND2P-C1V-P-A by the flange

receptacle.

Positions are specified via an analogue setpoint signal (4 … 20 mA), for example

via a master PLC/IPC or manually on-site via an external setpoint generator. Posi-

tioning of the piston rod/slide gate is by means of closed-loop control.

The integrated positioner performs position control of the piston rod within the

available stroke range.

The integrated displacement encoder transmits the current position to the internal

positioner as an analogue signal. The positioner cyclically compares the setpoint

and actual positions and transmits appropriate positioning signals to the integ-

rated valve manifold for positioning control.

Document Outline

- Linear drive DFPI-...-...-ND2P-C1V-...-A English