Ntellisys, Daptive, Ressure – Nor-Cal Intellisys Adaptive Pressure Controllers User Manual

Page 42: Ontrollers, 0 - product support, Troubleshooting

42

42

Visit our Web Site

www.n-c.com

I

ntellIsys

A

dAptIve

p

ressure

C

ontrollers

APC-OP-LIT 1/12

12.0 - Product Support

CAUTION:

DO NOT open the enclosure. Damage to equipment may occur, and unauthorized access to internal parts will void the warranty.

Troubleshooting

Some basic troubleshooting can be done by the user referring to the instructions and suggestions in the table below which describes common symptoms

and recommended actions. The Nor-Cal Products’ APC controller module is designed for years of maintenance free operation. Electronics MTBF has been

determined to be in excess of 10,000 hours continuous operation. There are no user serviceable parts or components inside the enclosure. If a problem does

occur with the APC control electronics or software, please refer to the basic troubleshooting instructions below or contact Nor-Cal Products Intellisys Customer

Support to obtain additional instructions or a Return Materials Authorization number.

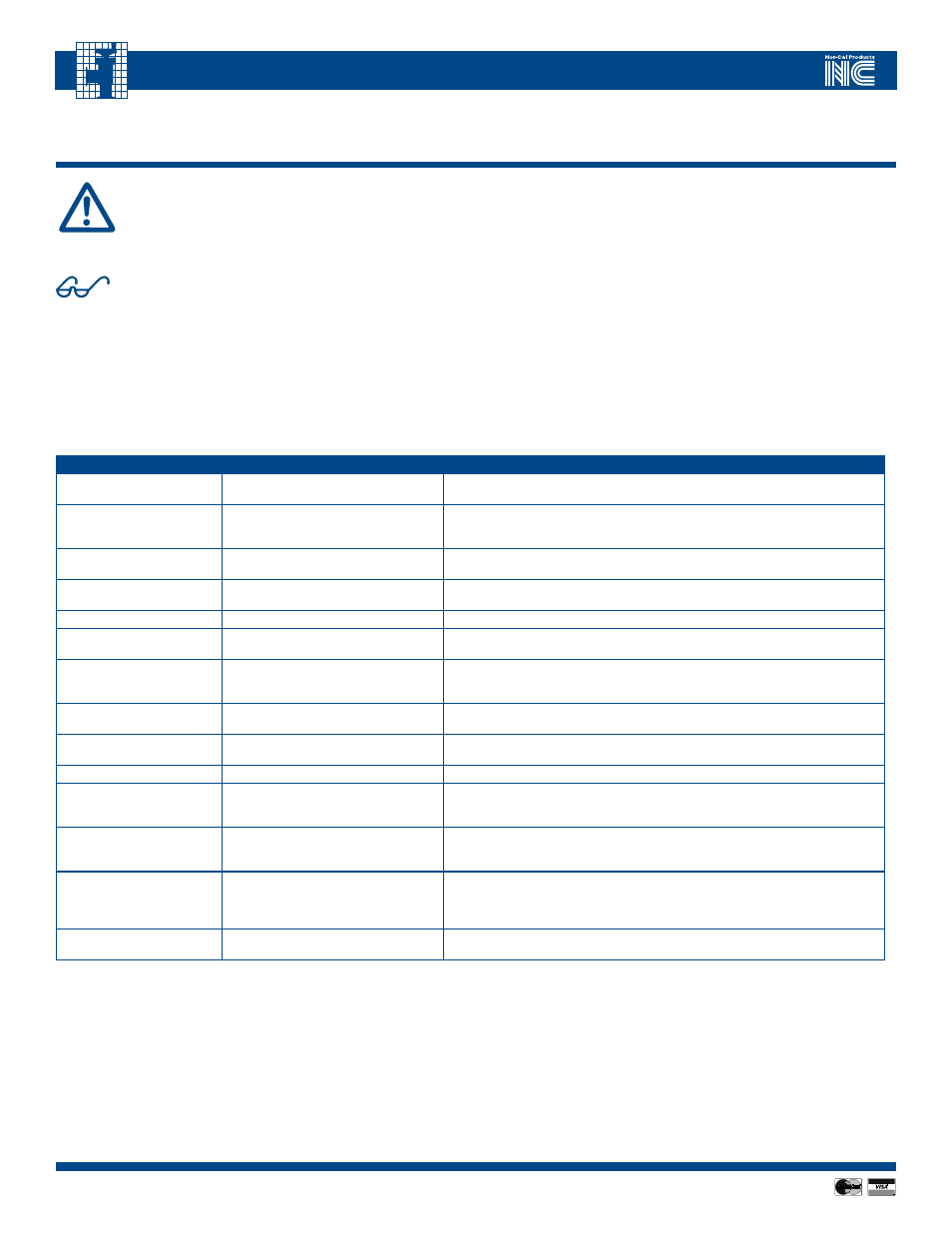

TAbLE 12.1 – POSSIbLE FAILURE mODES AND RECOmmENDED ACTIONS

SymPtom

PoSSIBle cAuSeS

recommenDeD ActIon

The APC does not appear to turn

on. No LEDs are illuminated

The APC is not receiving power properly

Check external power supply, cabling and pin assignments. Try to restart the APC by

reconnecting power supply. Operate OPEN/CLOSE switches.

The APC is on (one or more

LEDs illuminated) but it will not

respond to commands

The initialization safety lock function is active.

The amber FAULT LED should be on and the

OPEN/CLOSE LEDs should be blinking.

Issue the JC command via the RS-232 serial port to execute the initialization sequence.

The RS-232 serial or Analog/TTL connections

are not properly made

Check cabling and pin assignments. Make sure CTS, RTS and DSR connections are not made.

Communication settings disagree between

the APC and the host

If RS-232 is used, make sure host is set for 9600 Baud, 1 stop bit and no parity.

Cycle power to the APC to refresh dip switch settings.

A communications timeout has occurred

Call for Intellisys Technical Support

The APC does not operate and

only the amber FAULT LED is on.

The valve plate and/or actuator is jammed

Cycle power to attempt re-initialization. Or, with power OFF, try to move valve plate by hand.

If stuck, call for Intellisys Technical Support.

There is something wrong with the motor

drive circuitry or the internal power supply

circuitry.

Call to obtain an RMA#.

The valve plate position does not

agree with the indicated position

The APC software has lost track of valve

position

Cycle power and allow for re-initialization. If problem repeats or persists,

call for Intellisys Technical Support.

Pressure control performance is

unsatisfactory

The APC is not receiving the gauge pressure

signal, or the signal is very noisy.

Check the gauge cabling and signal stability. Also, check for electrical noise or system

vibrations, especially if a 100 mTorr (or similar) gauge is used.

The APC is in valve position control mode

Put the APC in the correct mode by issuing the proper RS-232 or DeviceNet command

System design or operating range may be

outside the capabilities of the Adaptive

Pressure Control Algorithm

Call for Intellisys Applications Support.

The controller / valve will not

respond to a new set point value

The new set-point value is too close to the

old set-point value

When using serial communications, the difference between two set-point values should be

more than 0.01%. When using analog/TTL communications, the new set-point has to be at

least 25 mV higher or lower than the old set-point.

There is too much noise on the set-point

signal (analog mode, only)

In order to not “chase moving targets” due to electrical noise, the APC will only accept

a new set-point value if the stability of the signal is within a 50 mV band. Set-point signals

with a high level of noise will therefore not be accepted and the controller / valve will

remain in its present mode.

The LEDs are illuminated in an

unknown fashion

Please refer to Table 12.2 on the next page describing valid LED combinations.

WARNING:

When working with or troubleshooting Nor-Cal APC products extreme care must be taken to avoid putting bodily parts

in or near the valve gate mechanism or other moving parts. These may move suddenly and unexpectedly, and many of them are driven

with sufficient force so as to cause significant harm and possibly even dismemberment. Nor-Cal Products recommends that a lock-out

and tag-out procedure be strictly followed whenever human physical intervention is required on all of its control valves.