Ntellisys, Daptive, Ressure – Nor-Cal Intellisys Adaptive Pressure Controllers User Manual

Page 25: Ontrollers

25

Call toll free

800-824-4166

or 530-842-4457

•

FAX 530-842-9130

I

ntellIsys

A

dAptIve

p

ressure

C

ontrollers

APC-OP-LIT 1/12

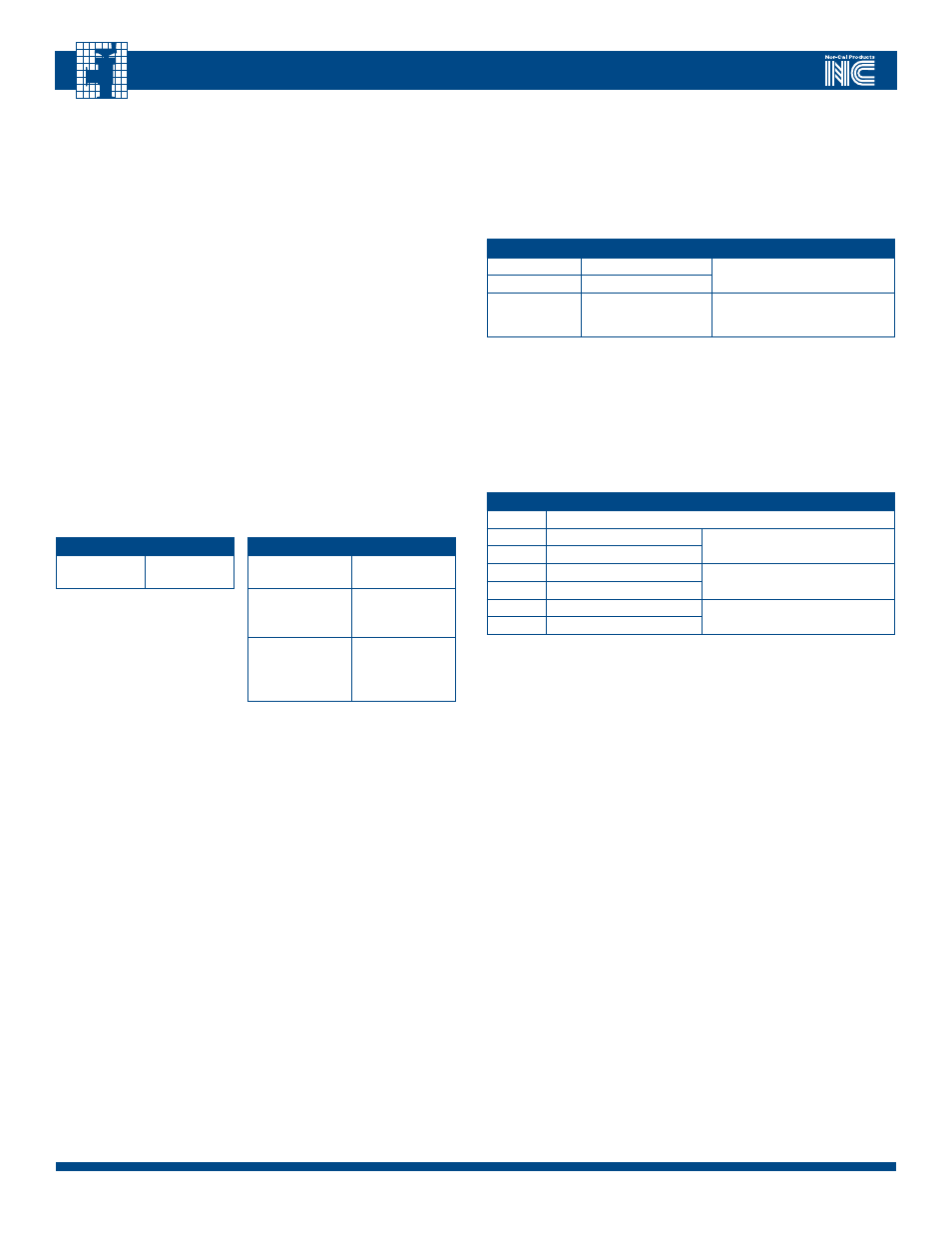

TAbLE 8.5

INPUT ASSEmbLy FORmATS

InStAnce

hex

vArIABleS

2

Exception status

Process variable

4

Exception status

Process variable

Control setpoint

5

(default)

Exception status

Process variable

Control setpoint

Valve position

TAbLE 8.4

OUTPUT ASSEmbLy FORmATS

InStAnce

hex

vArIABleS

7

(default)

Control setpoint

Control instance

how to read system pressure and valve position:

•

Select the service code

0E

(get attribute)

•

Select class ID

31

(select the s-analog sensor object)

•

Select instance ID

1

(process input CDG1)

•

Select attribute ID

6

(value attribute)

•

The device will respond with data bytes 00 00

meaning that the measured pressure is 0

•

Select instance ID

3

(valve position)

•

Select attribute ID

6

(value attribute)The device will respond

with data bytes

FF 7F

meaning that the valve position is full open

Input / Output messaging:

I/ O messaging is used to read and write data to the device on a periodic basis.

They are used for transmission of a continuous stream of data such as setpoint

or process pressure. I/O messages have limited overhead and rely on a prear-

ranged set of data called assemblies. The IQD controller handles input assem-

blies and output assemblies in a poll connection. In an I/O poll connection the

master periodically sends an output assembly and the slave responds with an

input assembly. The IQD Controller supports one output assembly and 3 input

assemblies format.

Example of I/O messaging transactions:

The following is an example format of a typical poll connection:

After having opened the I/O connection the master sends the following data:

Byte

DeScrIPtIon

DAtA rAnGe

1

setpoint (low byte)

0 to 7FFFhex

2

setpoint (high byte)

3

setpoint destination

01 pressure control high gauge

02 valve position control

03 pressure control low gauge

Note:

The setpoint is a number from 0000 to 7FFF covering the range 0 to

100%. In other words, in pressure control mode, 7FFFhex represent full scale

of the primary pressure gauge, if the pressure gauge used is 1 torr then a set

point of 4000hex will control pressure to 0.5 torr.

In valve position control mode, 7FFFhex represents full open stroke.

Respectively, 0000hex setpoint corresponds to closing the valve and 7FFFhex

corresponds to a full open the valve.

The controller response is formatted accordingly:

Byte

DeScrIPtIon

DAtA rAnGe

1

exception status

2

pressure (low byte)

0 to 6000hex

3

pressure (high byte)

4

setpoint (low byte)

0 to 7FFFhex

5

setpoint (high byte)

6

valve position (low byte)

0 to 7FFFhex

7

valve position (high byte)