Ntellisys, Daptive, Ressure – Nor-Cal Intellisys Adaptive Pressure Controllers User Manual

Page 14: Ontrollers, 0 - theory of operation, Initialization sequence, Normal operation, Tuning

14

14

Visit our Web Site

www.n-c.com

I

ntellIsys

A

dAptIve

p

ressure

C

ontrollers

APC-OP-LIT 1/12

Initialization Sequence

When first powered up, the APC controller will run the valve through an

initialization sequence that lasts for approximately 30 seconds. The primary

purpose for this operation is for the controller to determine the fully open

and closed points, as well as for certain motor and position calibration steps

to occur. While the initialization sequence is active, the amber FAULT light will

be illuminated and the OPEN/CLOSE LEDs will blink in an alternating fashion.

Once the initialization sequence is complete, the valve will move to the fully

open position and the green OPEN LED will illuminate.

NOTE:

The controllers for TPV pendulum valves and TSS

gate valves contain a valve initialization safety lock function.

This safety lock will prevent valve initialization to occur until

given a “clear-to-proceed” command. The RS-232 serial

command for this is JC. Alternatively, the \Valve Initialization

Enable In\ TTL pin can be pulled low to initiate this sequence.

CAUTION:

Never attempt to initialize a throttle valve with

differential pressure across the sealing gate. Make sure the

pressure on both sides is equalized. Damage to pumps and

other equipment can occur otherwise.

4.0 - Theory of Operation

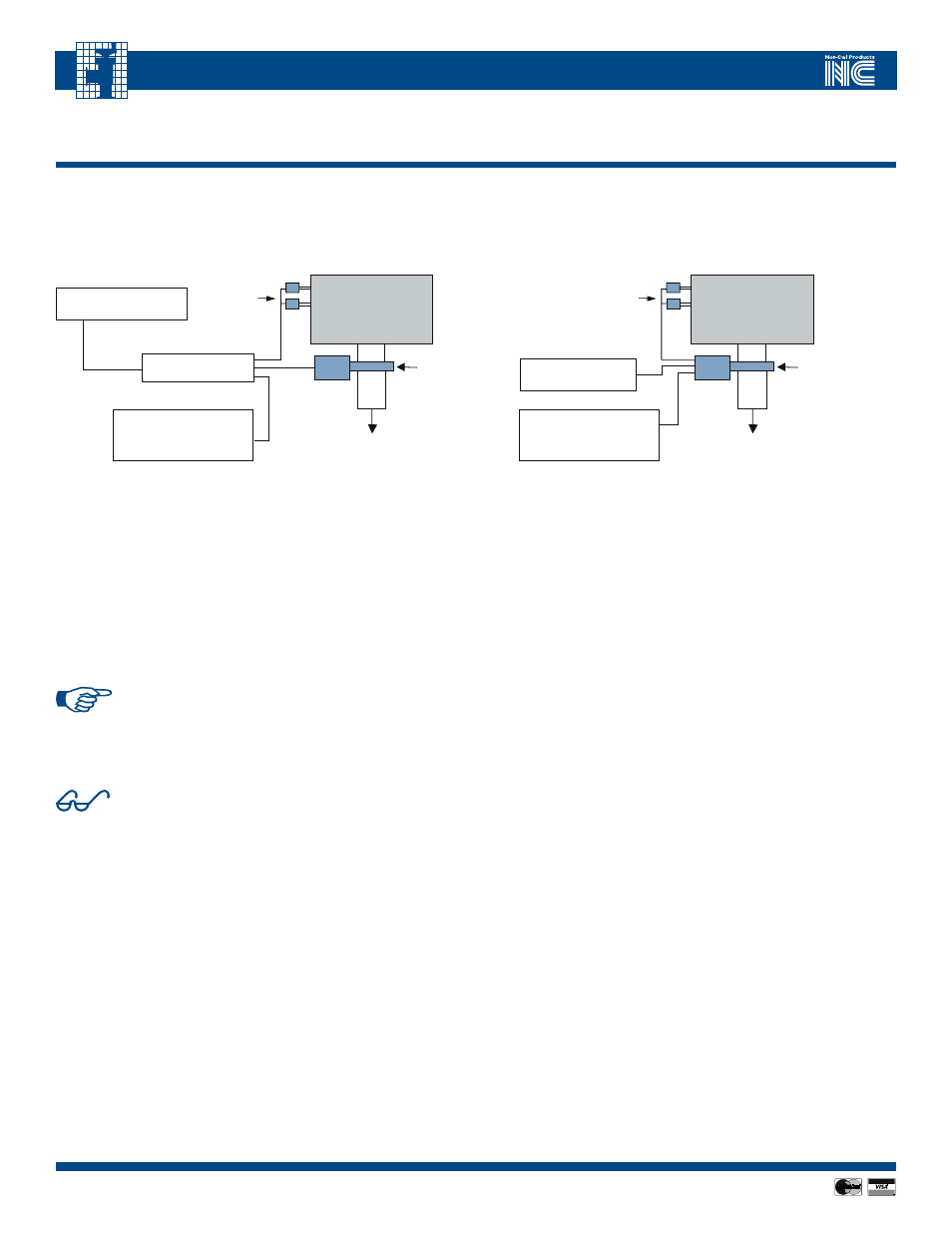

All APC controllers are designed for downstream pressure control (see Fig 4.1 and 4.2). As such, it is one of four important components in a pressure

control system. The other three essential components include a host system computer, a throttle valve and one or two vacuum gauges, such as a

Capacitance Diaphragm Gauge (CDG). Most manufacturers’ vacuum gauges can be used to provide the vacuum measurement signal, provided

they have a voltage output proportional to pressure.

Vacuum Chamber

Pump

DC power supply

Host system with

RS232/485 or DeviceNet

communications

Nor-Cal

IQ-series

Valve

Vacuum

gauge(s)

FIGURE 4.1 – TyPICAL INSTALLATION AND CONFIGURATION OF A bURIED

bOX INTELLISyS DOWNSTREAm PRESSURE CONTROL SySTEm

FIGURE 4.2 – TyPICAL INSTALLATION AND CONFIGURATION

OF AN Iq PRESSURE CONTROL VALVE

Vacuum Chamber

Pump

AC or DC power supply

Host system with

RS232/485 or DeviceNet

communications

APC Controller

Nor-Cal

throttle

valve

Vacuum

gauge(s)

Normal Operation

After the initialization sequence is complete normal operation of the valve is

possible. There are two primary modes of operation, a) position control mode

and b) pressure control mode.

In

position control mode

, the valve will move to any position in its range

based on a position set-point command from the host. The valve will remain

in that position until instructed to do otherwise. Position control mode can

be useful in certain cases where pre-determined amount of baffling or

throttling is necessary.

Pressure control mode

, on the other hand, is used whenever control to a

specific system pressure level is desired. The host provides the set-point value

to the controller which, in turn, moves the valve to achieve that set point as

quickly as possible. During pressure control mode, external perturbations

such as flow changes and plasma events will automatically be compensated

for by the controller so that the pressure set-point is maintained. The set

point value can be changed by the host at any time.

Tuning

The APC controller contains an Adaptive Pressure Control Algorithm that

has been designed to work over a wide range of flow and pressure combina-

tions. The APC controller therefore does not have a “learn mode” and there

is no need for the user to set PID parameters. In some instances, however,

vacuum system design may affect the closed loop pressure control time

constants. As a result, pressure control performance may at times be

affected. If satisfactory pressure control cannot be achieved with the

Adaptive Pressure Control Algorithm, please contact Nor-Cal Products’

Intellisys Customer Support.