Maintenance, 3 fault codes – Glow-worm Ultracom2 35 Store User Manual

Page 40

0020112185_PROTO_13 - 01/11 - Glow-worm

- 38 -

• Check that there is a gas supply to the boiler and the gas

service isolation valve is turned on.

• Check pressure at the gas service isolation valve.

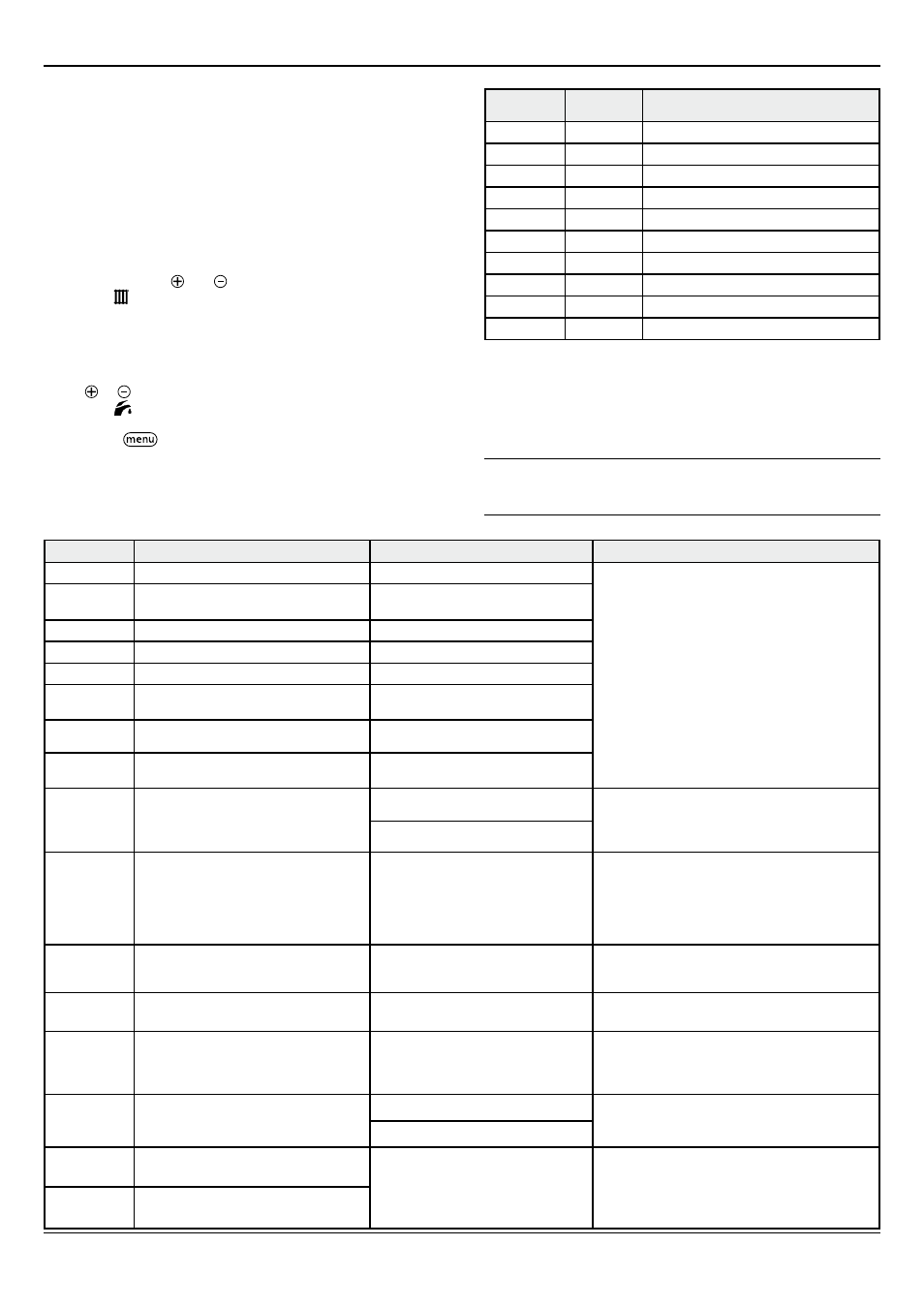

15.2 fault memory

• This menu allows you to display the 10 most recent failure

codes registered by the appliance.

• In order to display the fault code memory, simultaneously

press the buttons and of the

h

eating temperature

controls for more than 7 seconds.

• The screen will display the first fault "01" (record) and "F.XX"

(fault code).

• To display the other faults registered by the appliance, press

the or button

of the

d

omestic hot water temperature

controls .

• Press

the

button

for more than 3 seconds to exit this

menu.

Record

fault code Description

01

XX

Consult the “Fault codes” chapter.

02

XX

Consult the “Fault codes” chapter.

03

XX

Consult the “Fault codes” chapter.

04

XX

Consult the “Fault codes” chapter.

05

XX

Consult the “Fault codes” chapter.

06

XX

Consult the “Fault codes” chapter.

07

XX

Consult the “Fault codes” chapter.

08

XX

Consult the “Fault codes” chapter.

09

XX

Consult the “Fault codes” chapter.

10

XX

Consult the “Fault codes” chapter.

• To erase the fault memory registered by the appliance, consult

the “Installation adjustments” chapter and use code “d.94”.

15.3 fault codes

i

The faults described in this chapter should be carried

out by a qualified engineer and if needed by the After

Sales Service.

fault codes

Description

Cause

Solution

F00

Flow heating temperature sensor fault

Sensor open circuit

• Check the sensor’s connections.

• Check the wiring harness.

• Check the sensor.

F01

Return heating temperature sensor fault

Return heating temperature sensor

disconnected

F02

Hot water temperature sensor fault

Sensor disconnected

F03

Storage tank temperature sensor fault

Sensor disconnected

F10

Flow heating temperature sensor fault

Sensor short-circuit

F11

Return heating temperature sensor fault

Return heating temperature sensor

shorted.

F12

Hot water temperature sensor fault

Hot water temperature sensor short

circuit

F13

Storage tank temperature sensor fault

Storage tank temperature sensor short-

circuit

F20

Overheating fault

Overheating safety device activated

(97°C)

• Check the operation of the pump.

• Check the wiring harness.

• Check that the flow and return heating isolation

valves are open.

Improper bleeding

F22

Water pressure of the installation (<0.3

bar)

Return water valve closed

Pump disconnected

Leak in the installation

• Fill the installation.

• Purge the installation.

• Check the pump connections.

• Check the flow and return heating sensor

connections.

• Check that there are no leaks.

F23

Maximum temperature difference

reached between return and flow heating Water circulation fault

• Check the flow and return heating sensor

connection.

• Check the pump speed.

F24

Water circulation fault

Malfunction of the pump (excessively

rapid temperature increase)

• Check that the flow and return heating isolation

valves are open.

F26

Fault in gas valve motor.

Disconnected or defective cables

• Check the gas valve connections.

• Check the operation of the gas valve.

• Check the operation of the condensate pump

(option).

F27

Flame detection fault.

Abnormal flame detection

• Check the flame detection electrode.

• Check the main board.

• Check the igniter unit.

Gas mechanism defective

F28

Ignition fault

No return gas / Insufficient gas flow

Gas valve incorrectly adjusted

Defective firing electrode and flame

control / Defective igniter unit

• Check the return gas circuit (gas valve open).

• Check the observe the flame picture and check

the CO

2

setting.

• Check the igniter unit connections.

• Check the state of the electrode (corrosion).

F29

Loss of flame during operation

MAINTENANCE