Installation, 12 commissioning – Glow-worm Ultracom2 35 Store User Manual

Page 30

0020112185_PROTO_13 - 01/11 - Glow-worm

- 28 -

12 Commissioning

i

At the time of commissioning, complete all relevant

sections of the Benchmark Checklist located in the

centre pages of this document.

The commissioning should be carried out by a competent person

approved at the time by the Health and Safety Executive and in

accordance with the current issue of BS6798.

12.1 Switching on

• Do not operate the boiler without water.

• Make sure that the system has been thoroughly flushed out with

cold water and that all cleanser if used has been removed.

• With the gas service isolation valve closed, with no demand

from any external controls and the power supply to the boiler

switched off.

• Test for gas soundness and purge air from the gas supply.

• Press the on/off button to activate the appliance.

• Make sure that the domestic hot water and heating functions

on your appliance are not activated.

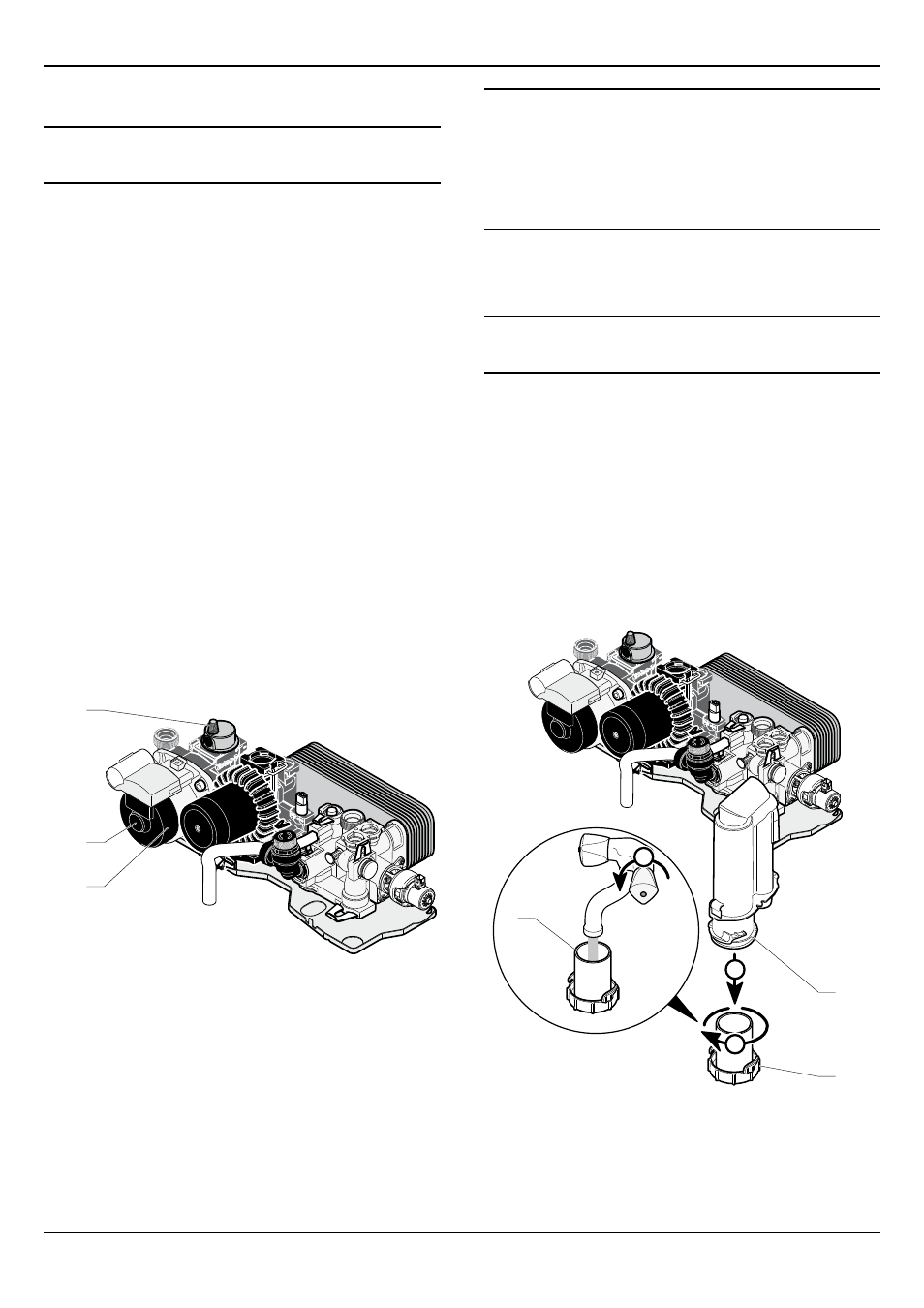

12.2 filling the CH system (Central heating)

• Make sure that the installation's cold-water inlet isolating

valve is open.

• Open isolating valves located on external filling loop: they

must be positioned in the direction of the flow.

3

2

1

Key

1 Air vent

2 Pump

3 Screw for the pump shaft

• Open the plug on the air vent located on the pump and the

automatic air vents on the installation.

• If the pressure shown on the pressure gauge is less than 0.4

bar, top up the installation by connecting external filling loop

to the appliance until you obtain a pressure of between 0.8

and 1.2 bars.

i

When turning the 230Vac supply on to the boiler

should the water pressure be less than 0.5 bar an

automatic air vent function will be activated for a

period of 5 minutes. During this time the pressure

should be increased and air vented from the system.

Note that the burner will not fire in either CH or DHW

mode and the display will blink displaying the current

water pressure.

• Vent air from each radiator until the water flows normally, then

close the vents.

• Leave the pump's air vent open.

i

The following two operations will unblock the pump's

engine after a prolonged storage period and will

purge the air from the pumps circuit.

• Remove the screw from the pump shaft and introduce a flat

screwdriver. A trickle of water, under no pressure, should

normally come out of the pump.

• Rotate the pump shaft through several turns, then replace the

screw.

12.3 filling DHW Circuit

• Open the various hot water taps to fill the DHW circuit.

12.4 filling the Condensate Trap

A

B

C

1

1

2

Key

1 filling trap

2 Condensate trap

• Fill the trap 3/4 full with water (1).

INSTALLATION