Trouble shooting chart for electric start models, Belt trouble shooting chart – Bolens 132-395A User Manual

Page 21

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

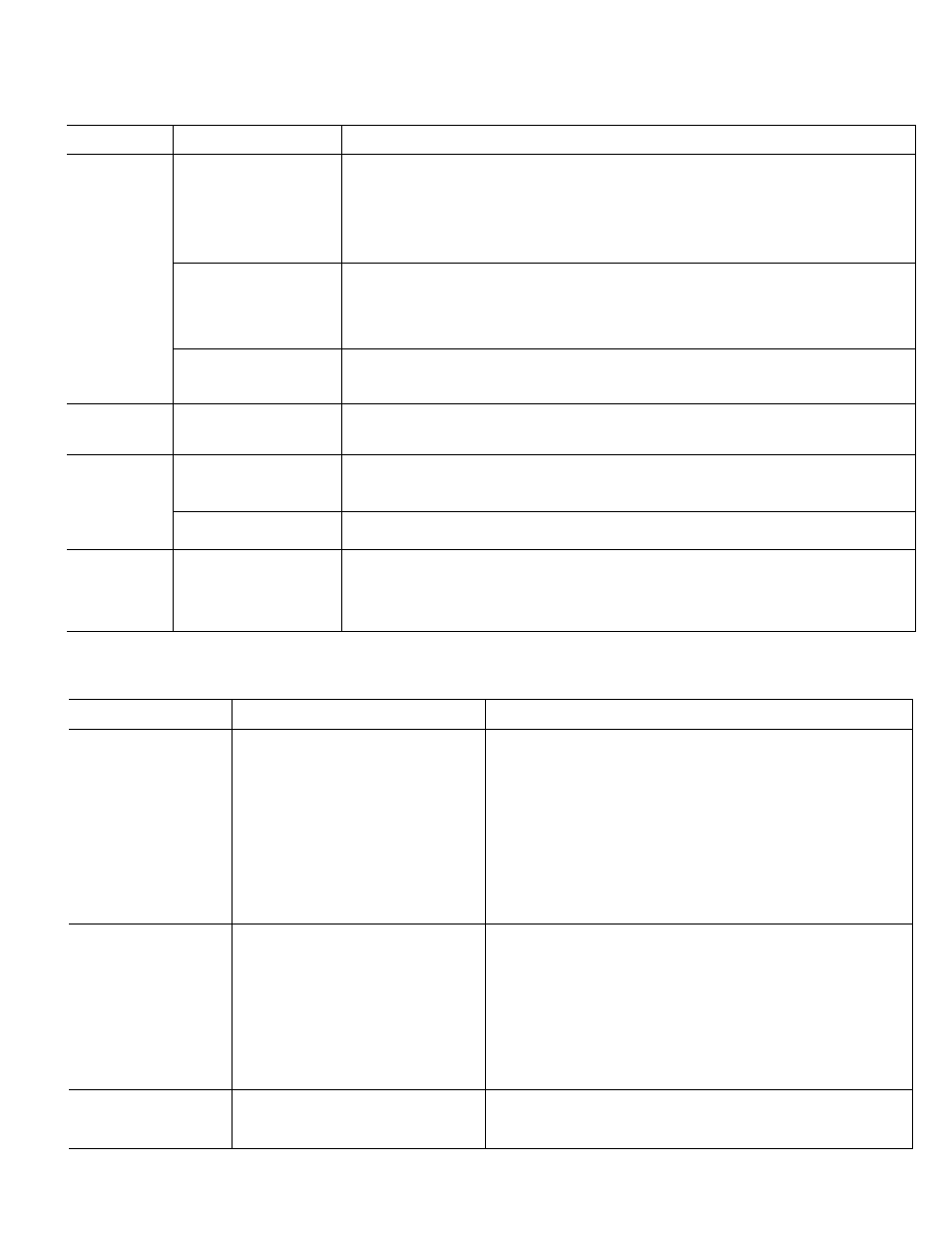

TROUBLE SHOOTING CHART FOR ELECTRIC START MODELS

TROUBLE

LOOK FOR

REMEDY

No spark to spark plug

Spark plug lead disconnected. Connect lead. Hold spark plug lead away from engine block

about 1/8". Crank engine. There should be a spark. If not, have engine repaired at authorized

engine service dealer.

Faulty spark plug. To test, remove spark plug. Attach spark plug lead to spark plug. Ground the

spark plug body against the engine block. Crank the engine. The spark plug should fire at the

electrode. Replace if it does not.

No fuel to the carburetor

Gasoline tank empty. Fill.

Fuel valve shut off. Open valve. Valve is located either at the bottom of the fuel tank or on the

carburetor.

Fuel line plugged. Remove and clean.

Airfilterdirty

If the air cleaner is dirty, the engine may not start. Ciean or replace as recommended by the

engine manufacturer.

Engine smokes

Engine loses crankcase

vacuum

Dipstick not seated or broken. Replace defective part.

Engine breather defective. Replace.

Excessive

vibration

Bent or damaged blade

spindle

Stop engine immediately.

Check all pulleys, blade spindles, blade adpaters, keys and bolts for

tightness and damage. Tighten or replace any damaged parts.

Bent blade

Stop engine immediately.

Replace damaged blade. Only use original equipment blades.

^ower will not

discharge

grass or leaves

jncu't strips

Engine speed low

Transmission selection

Blades short or dull

Throttle must be set between 3/4 and full throttle.

Use lower transmission gear. The slower your ground speed, the better the quality of cut.

Sharpen or replace blades (uncut strip problem only).

BELT TROUBLE SHOOTING CHART

Failure

Probable Cause

Corrective Action

1 Broken Belt

1A Sudden stop or shock load

to belt

IB Incorrect belt used

1C Abrupt engagement

ID Defective or damaged belt

1A Inspect rider for cause such as foreign objects stuck in

between deck and frame or belt path. Remove obstruc

tion and inspect for damage. Replace belt per parts list in

this manual.

1B Replace with proper belt only. See parts list in this manual.

Roll belt onto pulley.

Do not

use a screwdriver to push or

pry belt onto pulley. The sharp bend can damage internal

cords.

1C Slower engagement required.

ID Refer to IB.

2 Belt Shreds

2A Belt guides or guards

incorrectly adjusted

2B Pulleys not aligned

2C Bad pulley—rough, rusty,

chipped, bent, frozen

bearing, etc.

2A Belt guides and guards should be adjusted to approxi

mately 1/16 to 1/8 inch from belt when in the engaged

position.

2B Realign pulleys to be within approximately 1/16 inch of

each other. Check with straight edge. Be sure fastening

hardware is tight.

2C Replace as necessary. Adjust as per 2B.

3 Belt Comes Off

3A Belt stretched

3B Broken or weak idler spring

3A Adjust as necessary when applicable. Refer to IB.

3B Replace.

21