J j j – Ariens 929001 User Manual

Page 14

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

CLUT^IN^*hf^

Figure 28

TRANSMISSION DRIVE BELT

(Gear Shift Models)

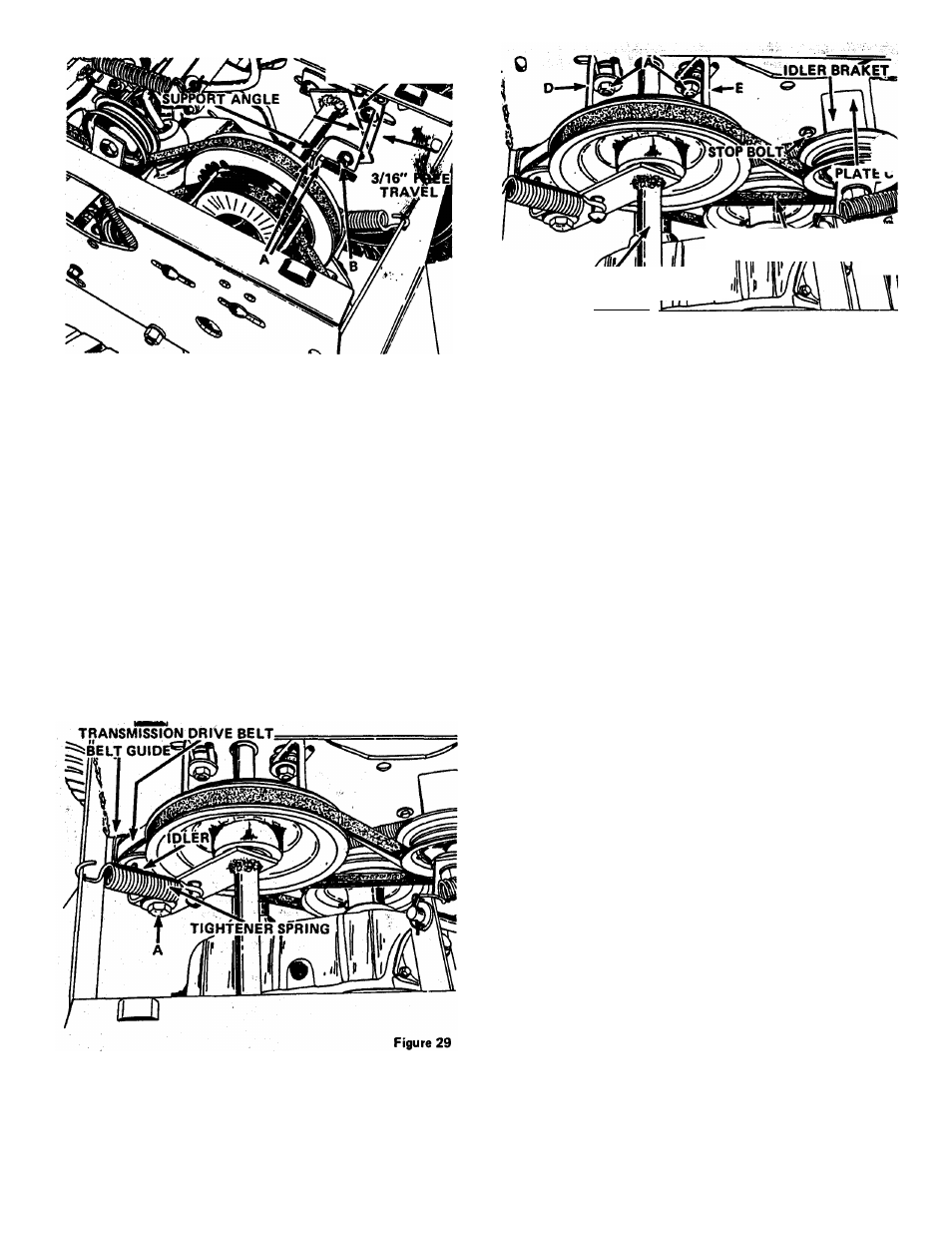

The transmission drive belt idler should be adjusted if the

drive belt slips or if the spring coils have bottomed out. See

Figure 29. Adjust by loosening bolt A and moving the idler

bapk in the slotted hole of the mounting bracket until the belt

does not slip and until there is clearance between the spring

coils. Before tightening bolt A, place the belt guide 1/8" from

the belt in such a position that it does not bind the belt in

any position of the idler.

Check belt guide D, Figure 30. It should be positioned

1/8" from the belt at the point where the belt enters the drive

sheave. Adjust by loosening the mounting bolt A and

positioning the guide as required.

NOTE: The dutch free-travel may be affected after adiusting

the drive belt Idler. Adjust if necessary as outlined under

"Clutch Free Travel Adjustment"

INTERMEDIATE SHAFT».

DRIVE BELT

SHAFT PARALLEL TO REAR OF

TRACTOR FRAME WITHIN 1/16"

' 111 *<|l ...................

J J J

INTERMEDIATE SHAFT DRIVE BELT

(Gear Shift Models)

Figure 30

To adjust the belt tension, loosen the four intermediate

shaft mounting bolts A and B, Figure 30, and move the shaft

rearward keeping it parallel to the rear of the tractor frame

until the front edge of the idler bracket is flush with the plate

identified at C.

NOTE; THE SHAFT MUST BE PARALLEL TO THE

TRACTOR FRAME WITHIN 1/16 INCH.

Adjust belt guides D and E 1/8" from the belt at the points

where the belt is tangent to the sheave and tighten the shaft

mounting bolts A and B.

t^OTE: The dutch free-travel adjustment can be affected

after tightening this belt Re-adjust as previously outlined

riecessary.

. k -

CTO DRIVE BELT (Implement Power)

Ж. .

The PTO drive belt should be adjusted before the rear

nuts B, Figure 31, contact the pivot block when the imple

ment power clutch is engaged or if the belt begins to slip.

Use the following procedure to adjust the belt:

1. Engage implement power clutch and tighten nuts C,

. Figure 31, until the spring length is 2-5/8".

NOTE: When making this adjustment, there must be clearance ,

between the rear nuts В and the pivot block. Move nuts В

rearward if necessary to obtain this clearance before measuring

ths spring length.

2. Position belt guides D and E, Figure 32, across from one

another when the clutch is disengaged in such a manner

that the belt is retained in the disengaged position. In ad

dition, guide D must clear the engine sheave by 1/8" as the

clutch is moved from the disengaged to the engaged

position. Move guide D rearward if necessary to obtain this

clearance.

3. With clutch disengaged, tighten nuts B, Figure 31, to ob

tain 1/4" clearance between the implement power clutch

lever and rear of slot in the tractor frame.

The intermediate shaft drive belt should be tightened if it

begins to slip or before the idler bracket contacts the stop

bolt as shown in Figure 30.

Page 14