Ariens 929001 User Manual

Page 11

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

GENERAL

Ariens dealers will provide any service which may be re

quired to keep the Lawn Tractor operating at peak efficiency.

Ariens Company recommends that you contact an Ariens

dealer before making any adjustments to this tractor. Refer

to the engine instruction manual and engine nameplate for

engine maintenance instructions. If repairs or service are re

quired for the engine, see your Ariens dealer or the nearest

authorized engine service station.

AIR CLEANER SERVICE

Clean the air cleaner and re-oil the element every 25 hours

under normal operating conditions. When operating in ex

tremely dusty conditions, perform this service at more fre

quent intervals. Use the following procedure to service the

air cleaner:

1. Raise the tractor hood. Remove screws A, Figure 19, and

lift off complete air cleaner assembly.

2. Remove screen and spacers from the foam element.

Figure 19.

3. Wash foam element in kerosene or liquid detergent and

water to remove dirt. Wrap foam in cloth and squeeze dry.

Let dry overnight.

4. Saturate foam element in clean engine. Squeeze to

remove the oil.

5. Re-assemble parts and re-install complete assembly on the

carburetor.

NOTE: When re-assembling the parts, make certain the foam

element extends over the edge of the air cleaner body. The

foam element will form a protective seal.

IMPORTANT:

NEVER

RUN

THE

ENGINE

WITH

THE

AIR CLEANER REMOVED!

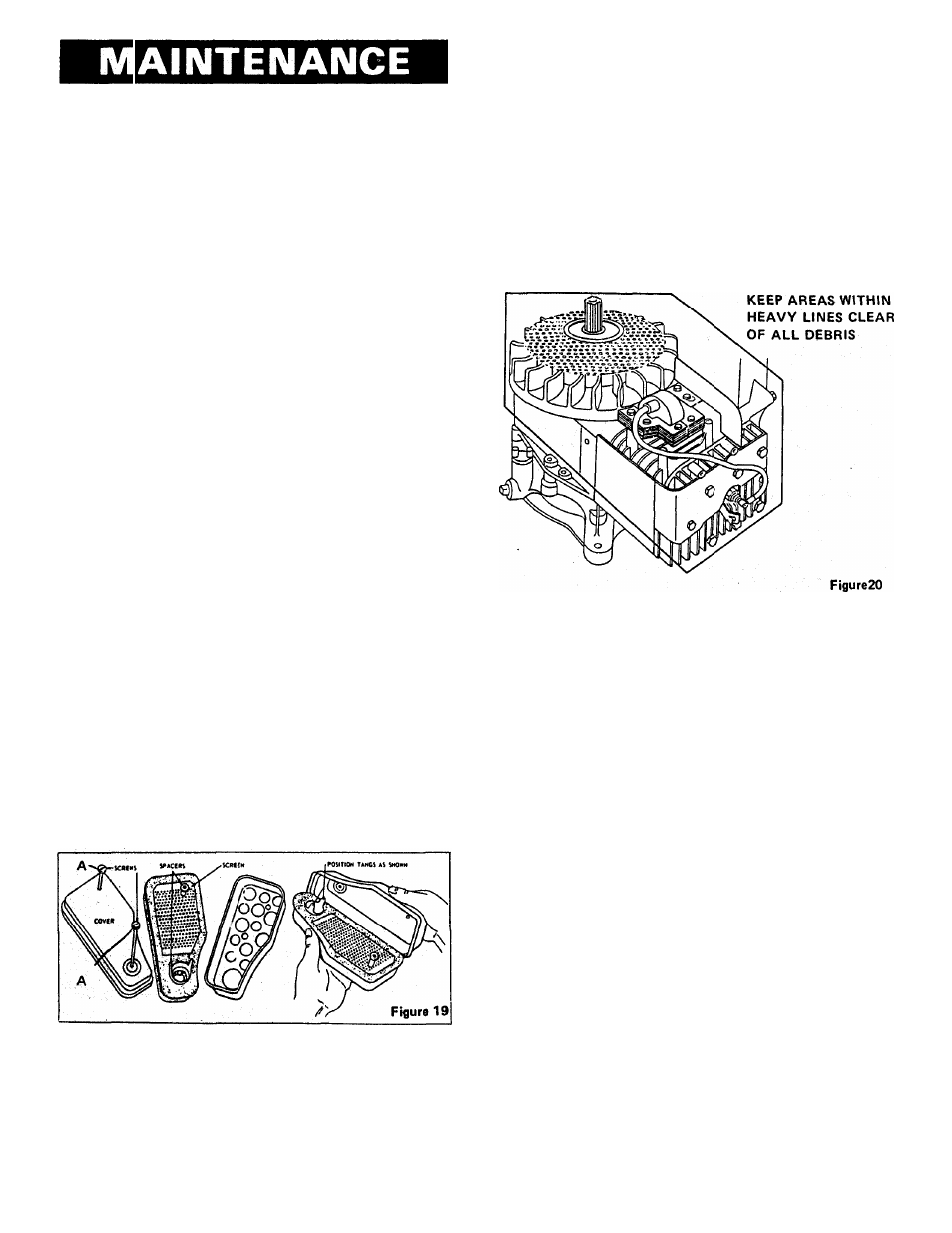

ENGINE COOLING SYSTEM

The engine is air cooled. Grass particles, chaff and dirt

may clog the cooling system, especially when mowing dry

grass or operating in extremely dusty conditions. Continued

operation with a clogged cooling system may cause severe

overheating and possible engine damage.

It is essential that the rotating screen, engine cooling fins

and the exhaust system be kept free of dirt and debris which

could causé the engine to overheat.

To avoid overheating and possible engine damage, period

ically remove the shrouding from around the cooling fins.

Figure 20, and clean the area shown within the heavy black

line of all grass, dirt or chaff accumulation.

TRANSMISSION COOLING SYSTEM

Dirt and grime accumulations on transmission cooling

fins can cause overheating. Check and clean the cooling fins

every 50 hours of operation or quarterly. In extremely

dusty or dirty conditions, clean the cooling fins more fre

quently.

CAUTION:

KEEP WA TER AWA V AND OFF RESERVOIR.

Check the hydrostatic cooling fan blades periodically to

assure that the blades are not bent or broken and that the fan

is in good condition.

BLEEDING THE TRANSMISSION

If for any reason the oil level is ever permitted to fall be

low the expansion reservoir, air may enter the system causing

the transmission to malfunction. If this should occur, use

the following procedure to "bleed" (remove air from the

transmission):

1. Thoroughly clean ail dust, dirt and grime from the free

wheeling valve, the oil filler cap and surrounding areas.

Figure 21.

2. Remove nut A, Figure 22 from the left end of the cam

assembly shaft and slide the cam assembly to the right until

the cam arm is free of the valve actuating rod.

3. Loosen nut B first and then valve actuating rod C, Figure

21, and remove the rod. Be extremely careful not to allow

dirt to enter the transmission.

4. Remove the expansion reservoir filler cap and add "Type

A" transmission fluid until the reservoir is % full.

5. Jack up rear of the tractor, start the engine and operate at a

slow idle speed.

6. With engine running, move speed control lever to both for

ward and reverse positions until oil appears at the free

wheeling valve hole.

7. Replace free-wheeling valve actuating rod C and tighten

nut B, Figure 21, to 30 inch-pounds. Tighten both parts

carefully to prevent the small rubber o-rings inside the cap

from becoming damaged.

Page 11