Friction wheel drive – Ariens 924 User Manual

Page 41

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Friction Wheel Drive

6.1 Introduction

A

WARNING: Remove wire from spark plug

before attempting any repair or adjustment

procedures.

When unit is tipped to preform the service proce

dures in this section, remove enough fuel so that

no spillage will occur, block securely and remove

bottom cover.

A

WARNING: Gasoline is highly flammable

and its vapors are explosive. Handle with

care.

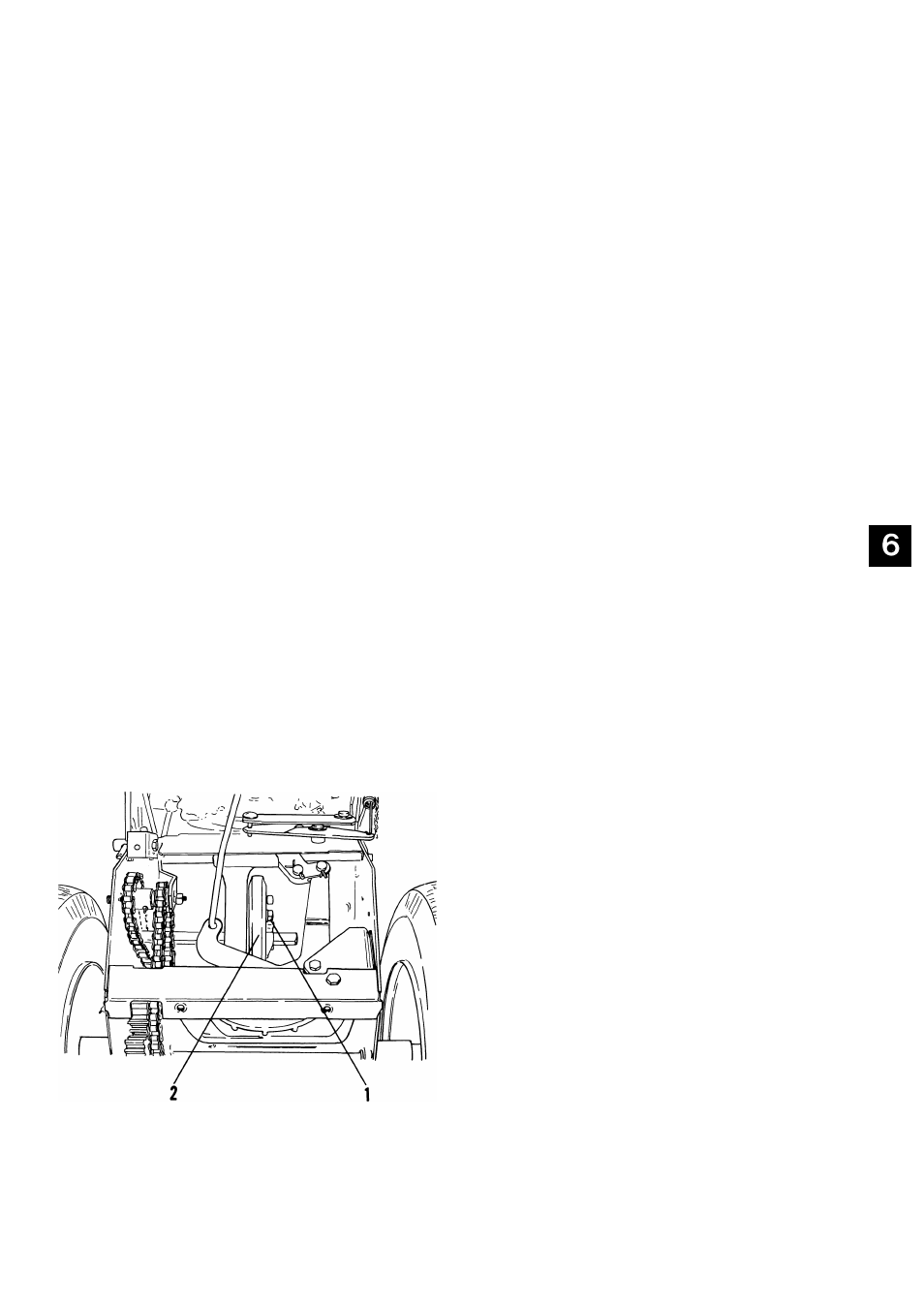

6.2 Friction Wheel

Remove bottom cover by removing four cap screws.

Place Speed Selector in first "1" position, depress

Traction Clutch Lever to hold friction wheel and

loosen five cap screws securing friction wheel to

hub. Release traction clutch lever, remove cap

screws, shift to third "3" position, disconnect

shift link and remove friction wheel.

Secure new friction wheel on hub with five cap

screws and torque cap screws to 8-10 foot pounds.

Install shift link.

6.3 Friction Wheel Carrier

Remove roll pins from carrier shaft and pull shaft

out of frame far enough to free carrier.

Hold hex shaft on sprocket end with a wrench and

remove lock nut at outside of frame. Slide hex

shaft to center of frame until it clears sprocket and

remove carrier from frame.

Remove nylon lock nut from spindle hub and hub

from carrier.

Remove snap ring, washer, bearing and bushing from

carrier.

Check carrier bushings and other parts for wear or

damage and replace as necessary.

Assemble in reverse order.

6.4 Drive Plate Spindle

Separate auger/impeller housing per instructions in

Auger/Impeller Section.

Remove lock nut from pulley end of spindle and

pulley from spindle. (To remove nut, engage friction

wheel drive to keep spindle from turning.)

Remove friction wheel carrier per previous instruc

tions.

Remove drive spindle housing from frame by re

moving three cap screws and lock washers from

housing.

Check spindle bearings and other parts for wear or

damage and replace as necessary.

Assemble in reverse order applying Locktite Anti

seize to outside of bearing housing.

NOTE: Mix 1 part Mobil 1 with 16 parts Locktite

No. 767 Antiseize.

1. Cap Screw

2. Friction Wheel

Figure 6-3: Friction Wheel

6-3