What to do when – Sears KENMORE 385.1915 User Manual

Page 99

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

What to do When

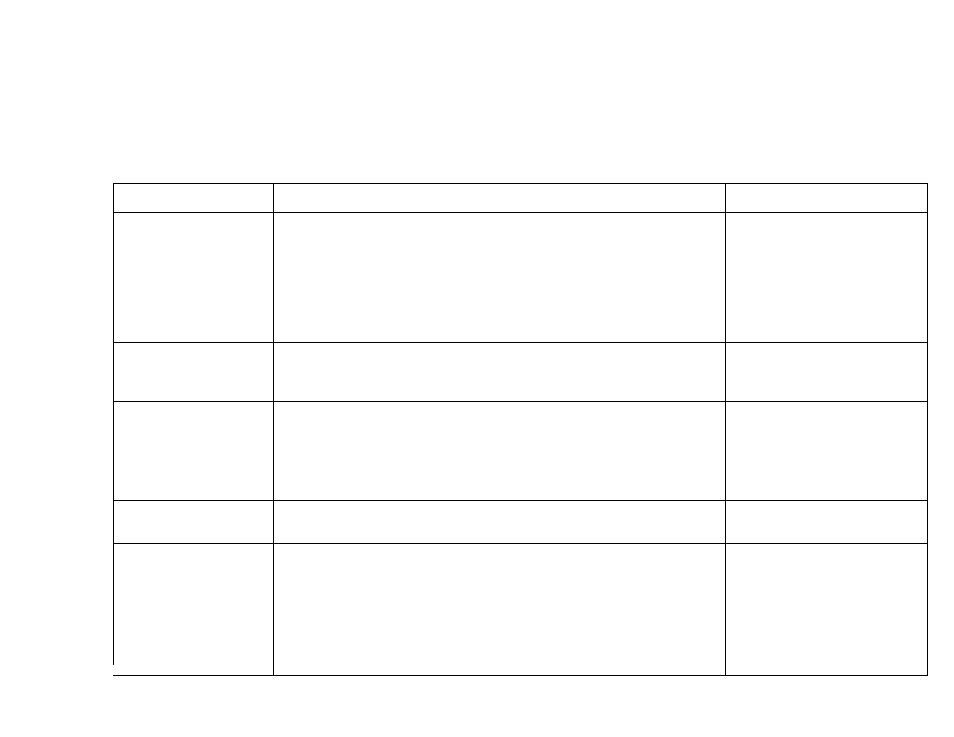

SECTION 6. PERFORMANCE PflOBLEMS CHART

/

...................... .......................

Condition

Cause

Reference

1. The needle thread is not threaded properly.

Refer to page 21

2. The needle thread tension is too tight.

Refer to page 23

3. The needie is bent or blunt.

Refer to page 17

The needie thread

4. The needle is incorrectly inserted.

Refer to page 17

breaks.

5. The needle thread and the bobbin thread are not set properly under (drawn to the

Refer to page 22

rear of) the presser foot when sewing is starting.

6. The fabric is not drawn to the rear when sewing.

Refer to page 47

7. The thread is too heavy for the needle.

Refer to page 17

1. The bobbin thread Is not threaded properly in the bobbin holder,

Refer to page 20

The bobbin thread breaks.

2. Lint has collected in the bobbin holder.

Refer to page 99

3. The bobbin ts damaged and doesn't turn smoothly.

Change the bobbin

1. The needle is incorrectly inserted.

Refer to page 17

2, The needle is bent or blunt.

Refer to page 17

The needle breaks.

3. The needle clamp screw is loose.

Refer to page 17

4. The tension of the needle thread is too tight.

Refer to page 23

5. The fabric is not drawn to the rear when sewing is finished.

Refer to page 47

6. The needle is too fine for the fabric being sewn.

Refer to page 17

Screen is not clear.

1. The sharpness of the liquid crystal display is not adjusted properly.

Refer to page 26

Readjust

1. The needle is incorrectly inserted.

Refer to page 17

2. The needle is bent or blunt.

Refer to page 17

3. The needle and/or threads are not suitable for the work being sewn.

Refer to page 17

Skipped stitches.

4. A blue tipped needle is not being used for sewing stretch, very fins fabrics and

Refer to page 17

synthetics.

5. The needle thread Is not threaded properly.

Refer to page 21

6. The presser foot pressure is not strong enough.

Refer to page 8

7. The wrong needle is used.

Change the needie

V. .

)

97