Fig. 30 — charging chart, Gas heat, Relief devices – Carrier 50LJ User Manual

Page 30: Control circuit, 115-v, Control circuit, 24-v

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

689

621

3^52

o

in

¡483

UJ

cc

S 41 4

in

cc

Q.

2 345

z

o

5276

:

d

in

207

1 1 1 M 1 1

OUTDOOR TEMP

F C

115 46

105 41

95 35

85 29

75 24

65 18

55 13

45 7

?"

ina.

2=

y' >

'

a:

13

in

in

1

>

" 1

X'

>

«

?

z

_J

y

orj

in

3

5

0

4

JCTION L

0

5

NE TEMPE

0

6

RATURE C

0

7

F)

0 8

0

1 1 1 1 1 1 1

-1 4 10 16 21 27

SUCTION LINE TEMPERATURE (C)

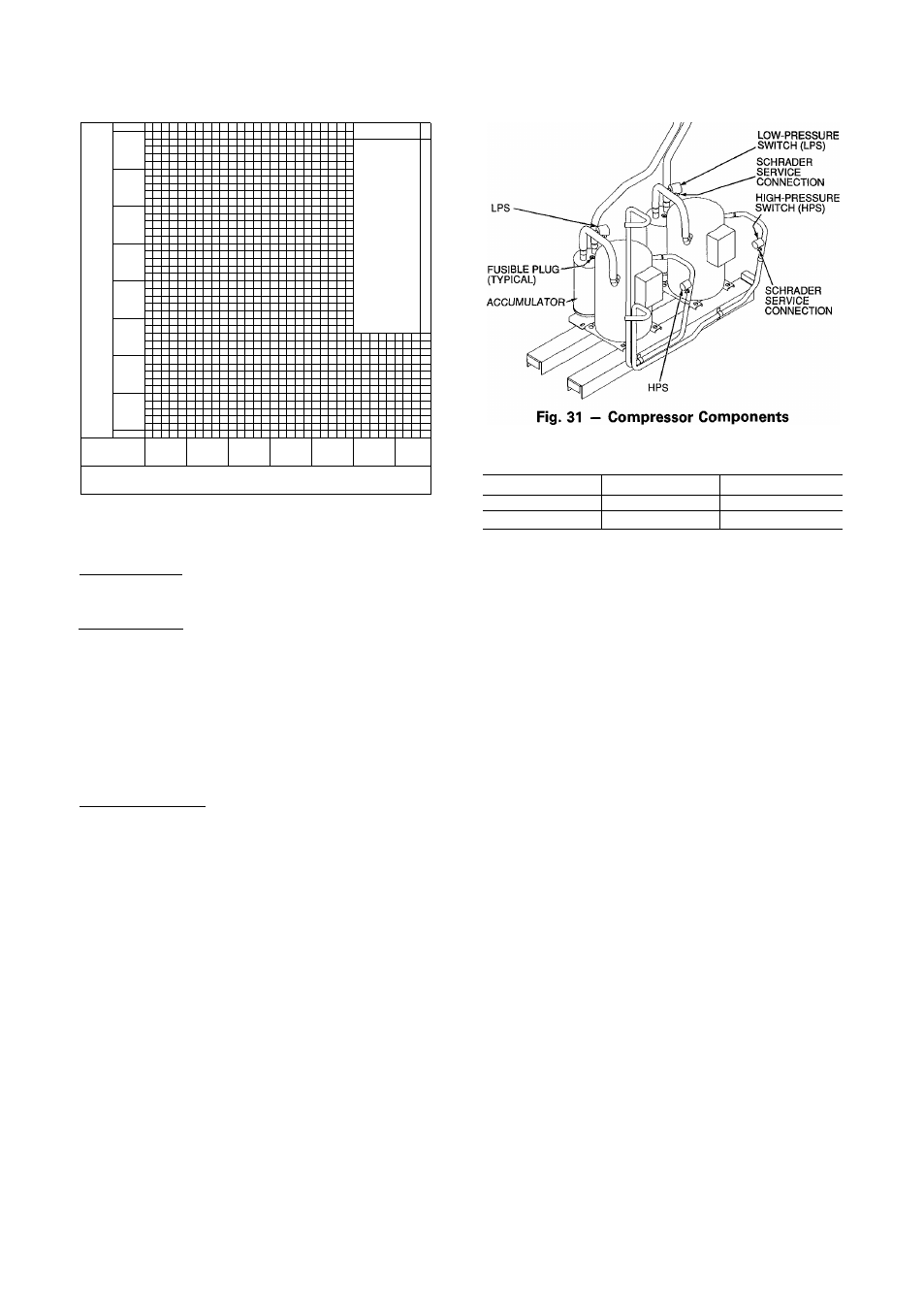

Table 6 - Pressure Switch Settings (psig)

Fig. 30 — Charging Chart

SWITCH

CUTOUT

CUT-IN

High

426 ± 7

320 ± 20

Low

7 ± 3

22 ± 5

Overtemperature — Each compressor has an internal pro

tector to protect it against excessively high discharge gas

temperatures.

r.rankcase Heater — Each compressor has a 70-watt crank

case heater to prevent absorption of liquid refrigerant by oil

in the crankcase when the compressor is idle. Since 115-v

power for the crankcase heaters is drawn from the unit con

trol circuit, main unit power must be on for the heaters to

be energized.

IMPORTANT: After a prolonged shutdown or ser

vice job, energize the crankcase heaters for 24 hours

before starting the compressors.

Compressor Lockout — If any of the safeties (high-, low-

pressure, compressor internal thermostat) trip, or if there is

loss of power to the compressors, the constant volume con

trol board will lock the compressors off. To reset, manually

move the thermostat setting.

EVAPORATOR FAN MOTOR PROTECTION - A man

ual reset, calibrated trip, magnetic circuit breaker protects

against overcurrent. Do not bypass connections or increase

the size of the breaker to correct trouble. Determine the

cause and correct it before resetting the breaker.

CONDENSER-FAN MOTOR PROTECTION - Each

condenser-fan motor is internally protected against over

temperature. Each motor is also protected against a severe

overcurrent condition by manual reset, calibrated trip, mag

netic circuit breakers. As with the circuit breakers

described previously, do not bypass connections or in

crease breaker size to correct trouble. Determine the cause

and correct it before resetting the breaker.

HIGH- AND LOW-PRESSURE SWITCHES - See Fig. 31

for compressor mounting locations. Settings for these switches

are shown in Table 6. If either switch trips, or if the

compressor overtemperature switch activates, that refriger

ant circuit will be automatically locked out by the constant

volume control board. To reset, manually move the ther

mostat setting.

Relief Devices

— All units have relief devices to pro

tect against damage from excessive pressures (i.e., fire).

These devices protect the high and low side.

Control Circuit, 115-V

- This control circuit is pro

tected against overcurrent by a 5-amp circuit breaker. Breaker

can be reset. If it trips, determine cause of trouble before

resetting.

Control Circuit, 24-V

— This control circuit is pro

tected against overcurrent by a 3.2-amp circuit breaker. Breaker

can be reset. If it trips, determine cause of trouble before

resetting.

Gas Heat

LIMITS SWITCHES — The maximum supply air temper

ature is controlled by a limit switch located in the compres

sor section. The limit is designed to trip at 100° F above the

maximum temperature shown in Table 1.

When the limit trips, the gas valve is deenergized and the

combustion air blower(s) and evaporator fan are held on

until the unit is cooled to its reset temperature. Once the

unit cools, the gas valve is reenergized.

If the thermostat stops calling for heat after the limit switch

trips, the combustion-air blower and evaporator fan are held

on until the limit cools to its reset temperature.

ROLLOUT SWITCH — This switch senses any flame or

excessive heat in the main burners and deenergizes the gas

valve. If this occurs, the gas heating system is locked out

until the rollout switch is reset manually. Reset by pressing

the button on the rollout switch. See Fig. 21 and 22.

When the rollout switch trips, it likely indicates a flue

blockage. Inspect the unit for any obstruction in the flue

system, for holes on the flue box, or for a defective

centrifugal switch or a loose combustion blower. See

Fig. 32 for proper location of the rollout capillary.

AIRFLOW SWITCH, 48LJE (HIGH HEAT) UNITS ONLY

— Shuts off the gas heat in the event there is a loss of air

over the gas cells. The airflow switch is located in the fan

section (see Fig. 5a — 5c). The switch will automatically

reset when airflow is sufficient.

30