Carrier 50LJ User Manual

Page 27

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

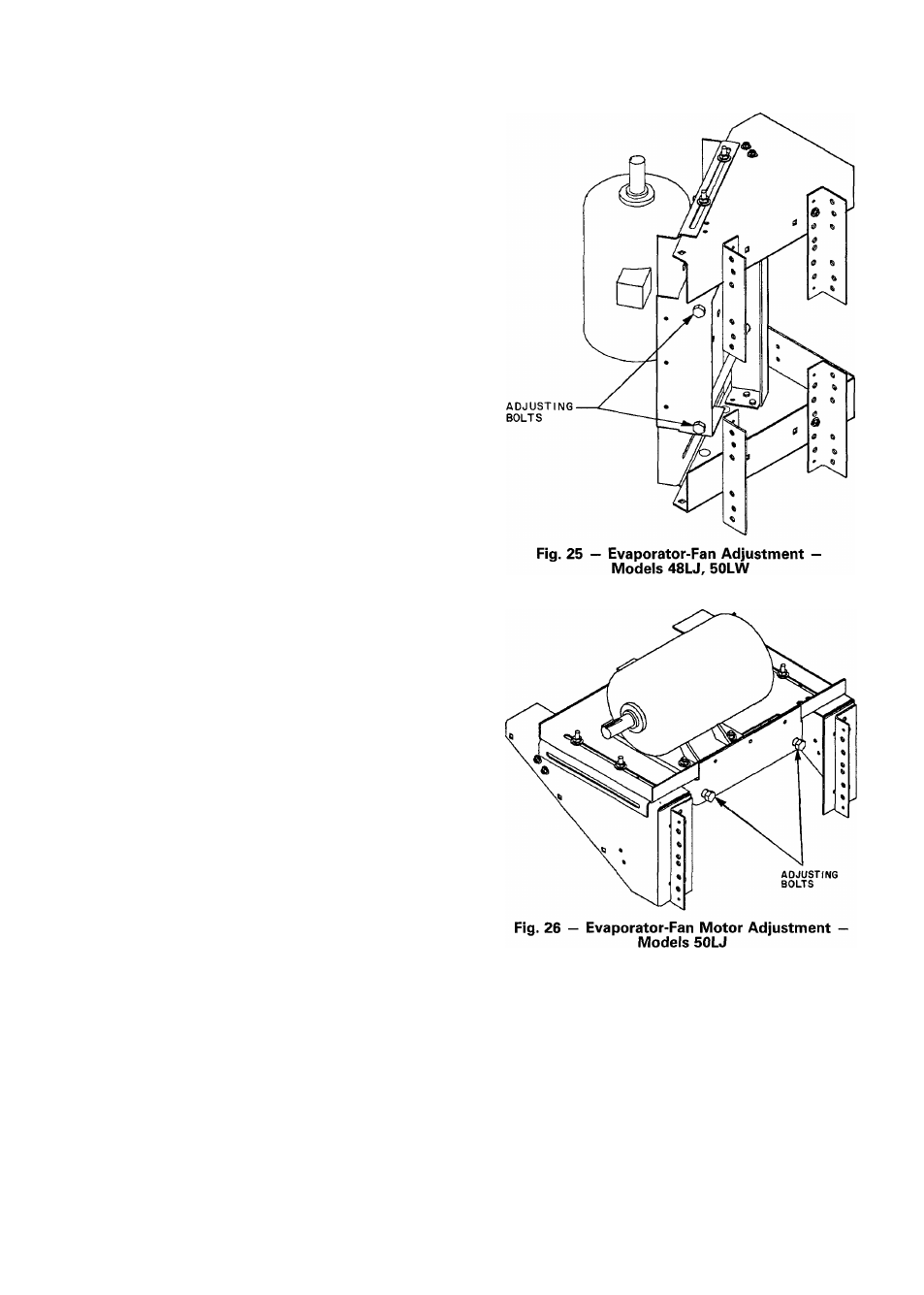

BELT INSTALLATION AND TENSIONING

NOTE: When installing or replacing belts, always use a

complete set of new, matched belts. Mixing belts often

results in premature breakage of the new belts.

1. Turn off unit power.

2. Adjust motor plate so belts can be installed without stretch

ing over the grooves of the pulley. (Forcing the belts

can result in uneven belt stretching and a mismatched

set of belts.)

3. Before tensioning the belts, equalize belt slack so that it

is on the same side of the belt for all belts. Failure to do

so may result in uneven belt stretching.

4. Tighten belts using the motor plate adjusting bolts.

5. Adjust until proper belt tension ('/

2

-in. deflection with

one finger) is obtained. Be sure to adjust both adjusting

bolts the same number of turns.

6. Check the tension at least twice during the first day of

operation; there is normally a rapid decrease in tension

until the belts have run in. Check tension periodically

thereafter and keep it at the recommended tension.

With the correct belt tension, belts may slip and squeal

momentarily on start-up. This slippage is normal and dis

appears after wheel reaches operating speed. Excessive belt

tension shortens belt life and may cause bearing and shaft

damage.

PULLEY ALIGNMENT — For proper belt life, the motor

and fan pulleys must be properly aligned. To check:

1. Turn off unit power. See Fig. 27.

2. Place a straight edge against the motor and fan pulleys.

If the pulleys are properly aligned, the straight edge should

be parallel to the belts.

3. If they are not parallel, check that the motor shaft and

fan shaft are parallel. If they are not, adjust the motor

plate adjusting bolts until they are.

4. After verifying that the shafts are parallel, loosen the

setscrews on the motor pulley.

5. Move pulley on the shaft until the pulleys are parallel.

6. To move the sheave on the shaft, loosen the belts. If

necessary, blower pulley can also be moved on the shaft.

INSTALLING FIELD-SUPPLIED ALTERNATE MO

TOR PULLEY — To install the alternate pulley:

1. Turn off unit power.

2. Loosen belts using motor adjusting bolts until belts can

be removed without stretching them over the grooves of

the pulley.

3. Remove belts.

4. Loosen setscrews on motor pulley.

5. Slide pulley off motor shaft. Make sure setscrews on

new pulley are loose.

6. Slide new pulley onto fan shaft and align it with the fan

pulley as described above.

7. Tighten setscrews.

8. Install belts and tension properly as described above.

CONDENSER FAN — To adjust condenser fans:

1. Turn off unit power.

2. Remove fan guard and loosen fan hub setscrew.

3. See Fig. 20 and adjust fan height using a straight edge

laid across the fan deck.

4. Tighten setscrew and replace rubber hubcap to prevent

hub from rusting to the motor shaft. Fill hub recess with

Permagum if hub has no rubber hubcap.

5. Replace fan guard.

27