Operating sequences – Carrier 50LJ User Manual

Page 23

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Economizer Dampers and Potentiometer Set

tings

— With no power to the unit, the economizer outdoor-

air dampers should be fully closed. Check by opening

the access door marked FILTER SECTION. On units with

economizer, be sure MAT and economizer minimum posi

tions are set at the desired settings. Be sure hood is in

stalled properly.

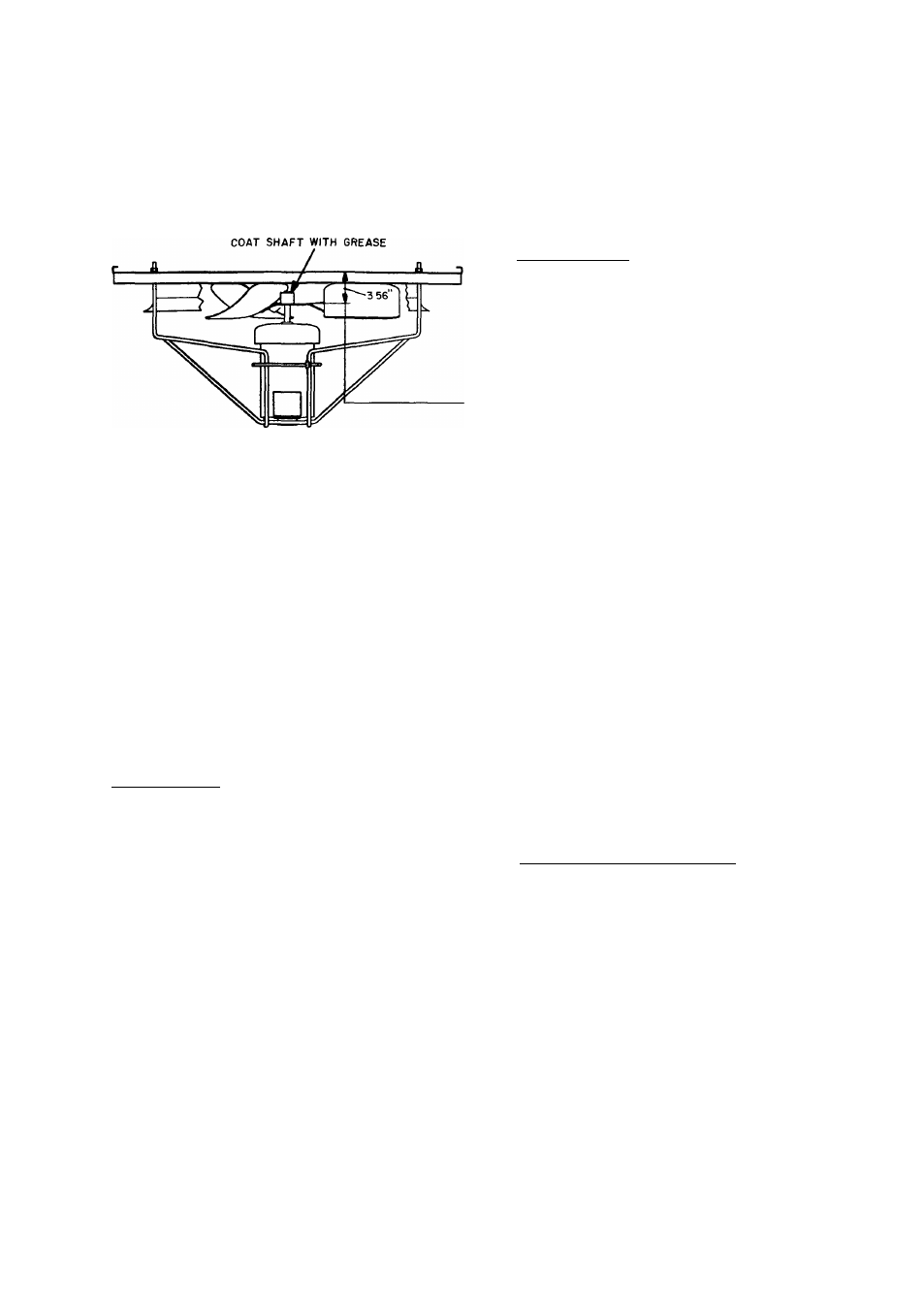

Fig. 20 — Condenser-Fan Adjustment

Operating Sequences

COOLING, UNITS WITHOUT ECONOMIZER - Set unit

power to ON position. Set system selector switch at COOL

or AUTO, position, and fan switch at AUTO, position. Set

thermostat at setting below room temperature.

Y1 on the thermostat closes, energizing Compressor

no. 1 as first stage of cooling. (Compressor no. 1 is closest

to the condenser coil.) The evaporator fan starts at the same

time as Compressor no. 1. If cooling load cannot be satis

fied with only first-stage cooling, Y2 on the thermostat will

close, energizing Compressor no. 2.

Condenser fans are energized with Compressor no. 1. The

no. 1 fan runs continuously while the unit is on mechanical

cooling; the no. 2 fan is cycled on and off for head pressure

control. Check cooling effects at a setting above room tem

perature. Compressors will shut off.

HEATING, UNITS WITHOUT ECONOMIZER

48LJD (Low Heatl — Purge gas supply line of air by open

ing union just ahead of the unit gas valve. When odor of

gas is detected, retighten union and wait 5 minutes before

proceeding.

Set unit power to ON position. Open manual gas valve

supplying gas to unit. Set thermostat system switch at HEAT

or AUTO, position, and set fan switch at AUTO, position.

First-stage thermostat (Wl) calls for heat. Induced-draft

contactor closes and induced-draft and evaporator-fan

motors start.

Centrifugal switch closes. Induced-draft motor operates

for 30 seconds to purge combustion tubes. Pilot valve opens,

allowing gas to flow to first-stage pilot. Spark ignitor

ignites pilot flame. Sensor detects flame, energizes main

gas valve coil and main gas valve opens. Gas flows to main

burners, and first-stage burners ignite. Spark ignitor shuts

off and pilot remains on.

The sparker will continue to spark for 90 seconds, or

until pilot flame is sensed. If the pilot fails to ignite or the

sensor fails to detect flame, the pilot valve closes, and the

spark ignitor shuts off for 330 seconds (51/2 minutes). Dur

ing this time, the induced-draft motor remains on to purge

any unbumed gas from the combustion tubes. This ignition

sequence will continue indefinitely.

On low-heat units 48LJD, when additional heat is needed

W2 is energized and a second coil in the main gas valve is

energized. This brings on an additional stage of heat. When

second-stage thermostat is satisfied, the second-stage gas

valve coil is deenergized.

When the first-stage thermostat is satisfied, first-stage main

gas valve and the pilot valve close. Induced-draft motor shuts

off. Evaporator fan motor stops.

48L.IE tHiuh Heat) — Purge gas supply line of air by open

ing union just ahead of the unit gas valve. When odor of

gas is detected, retighten union and wait 5 minutes before

proceeding.

Set unit power to ON position and open manual gas valve,

supplying gas to unit. Set thermostat system switch at HEAT

or AUTO, position, and set fan switch at AUTO, position.

First-stage thermostat (Wl) calls for heat and evaporator

fan starts.

When evaporator fan starts, airflow switch closes, clos

ing induced draft contactor, and induced draft motor starts.

Centrifugal switch closes. The induced-draft motor

operates for 30 seconds to purge combustion tubes. Pilot

valve opens, allowing gas to flow to first-stage pilot. Spark

ignitor ignites pilot flame. Sensor detects flame, energizes

main gas valve coil, and main gas valve opens. Gas flows

to main burners and first-stage burners ignite. Spark ignitor

shuts off and pilot remains on.

The sparker will continue to spark for 90 seconds, or

until pilot flame is sensed. If the pilot fails to ignite, or the

sensor fails to detect flame, the pilot valve closes, and the

spark ignitor shuts off for 330 seconds (51/2 minutes). Dur

ing this time, the induced-draft motor remains on to purge

any unbumed gas from the combustion tubes. This ignition

sequence will repeat indefinitely.

When additional heat is needed, W2 is energized after a

30-second delay. Pilot valve no. 2 opens, allowing gas to

flow to second-stage pilot. Spark ignitor ignites pilot flame.

Sensor detects flame, energizes main gas valve coil, and

main gas valve no. 2 opens. Gas flows to main burners and

second-stage burners ignite. Second-stage spark ignitor shuts

off. The induced-draft motor operates for 30 seconds to purge

combustion tubes. When the second-stage thermostat is sat

isfied, W2 is de energized and the second gas valve is shut

off.

When the first-stage thermostat is satisfied, first-stage main

gas valve and the pilot valve close. Induced draft motors

and evaporator-fan motor shut off.

50LJ (With Optional Electric Heat) — Set unit power at

ON position. Set system selector switch at HEAT position,

and set fan switch at AUTO, position. Set thermostat at

setting above room temperature.

When Wl on the thermostat closes, the first stage of elec

tric heat is energized. On a further drop in room tempera

ture, W2 on the thermostat closes, energizing the second

stage of electric heat.

NOTE: Units equipped with low electric heat option have

only one stage. Reset thermostat to a setting below room

temperature. Unit should shut off.

COOLING, UNITS WITH ECONOMIZER - With sub

base switch set at COOL and fan switch set at AUTO.,

evaporator fan is energized when Y1 on thermostat closes.

If enthalpy is below setting on enthalpy switch, the econo

mizer outdoor-air dampers will modulate open to satisfy the

cooling requirement. (Evaporator-fan motor heat should be

considered when evaluating the use of outdoor air to satisfy

23