Protective devices – Carrier 50LJ User Manual

Page 29

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

ENTHALPY CONTROL, MAT, AND ECONOMIZER

DAMPER VENT POSITION — See Installation section of

this publication for adjustment procedures.

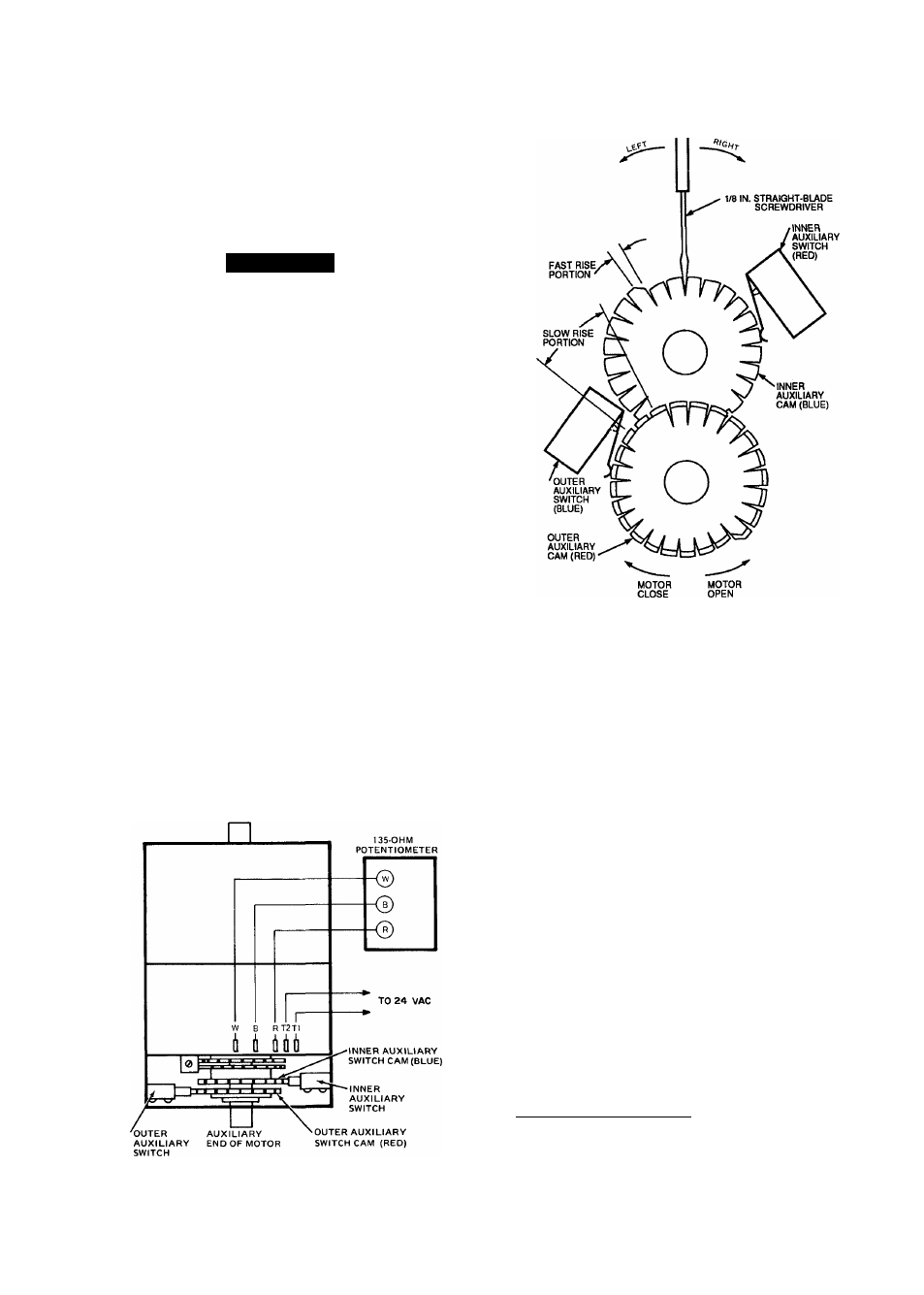

AUXILIARY SWITCH — All units have an auxiliary switch

located on the economizer damper motor. This switch is

factory set to prevent the power exhaust from operating when

the economizer damper is less than 50% open. If other than

the factory setting is desired, follow the steps below.

A

CAUTION

Do not turn motor shaft by hand or with a wrench.

Damage to the gear train will result.

TO ADJUST CAMS,

MOVE TOP OF SCREWDRIVER ONLY

2

.

Remove top cover from motor to gain access to motor

terminals and cam adjustments.

Disconnect controller from motor. Connect red, white,

and blue terminals on the 135 ohm manual potentiome

ter to corresponding red, white and blue terminals on

the motor. Connect 24-vac power to Terminals 1 and 2.

See Fig. 28.

3. Adjust the 135-ohm potentiometer so that the motor shaft

turns to the position where auxiliary equipment is to be

switched.

4. Adjust auxiliary cam by inserting a Vs-in. straight blade

screwdriver into slot on cam and moving TOP of screw

driver to the right or left. See Fig. 29.

5. To close auxiliary switch red and blue contacts as the

motor travels open (energizing the power exhaust mo

tor), the switch differential can only be 10 degrees on

both switches. To adjust either cam, perform the fol

lowing steps:

a. If red and blue contacts are open, rotate the cam

counterclockwise until the contacts close.

b. If the red and blue contacts are closed, rotate the cam

clockwise until the contacts open.

6. Check for proper auxiliary switching (including differ

ential) by mnning motor through full stroke, using 135

ohm potentiometer. Repeat adjustment if necessary.

7. Disconnect 135 ohm potentiometer, reconnect control

ler and place top cover on motor.

AUXILIARY END VIEW

Fig. 28 — Auxiliary Switch Stroke Adjustment

Fig. 29 — Auxiliary Switch Adjustment

NOTE: Adjusting the auxiliary switch does not require run

ning the motor.

REFRIGERANT CHARGE — All units are shipped with a

complete operating charge of R-22. See unit nameplate and

Tables la and lb for amount of charge. When charging

refrigerant system, refer to Carrier Standard Service Tech

niques, Refrigerants section. When adding a complete charge,

evacuate system using standard evacuating procedures and

weigh in the specified amount of charge. See Fig. 30 for

refrigerant circuit charging chart.

Refrigerant Feed Components

— Each refrigerant

circuit (2 per unit) has all the necessary refrigerant

controls.

Acutrol™ Refrigerant Metering Device

- Each

circuit has 12 non-adjustable metering devices. They con

trol the flow of liquid refrigerant to the evaporator coils.

Filter Drier

— Replace whenever refrigerant system is

exposed to atmosphere.

Protective Devices

COMPRESSOR PROTECTION

Overcurrent (208/230 v onlvl — Each compressor has one

manual reset, calibrated trip, magnetic circuit breaker. Do

not bypass connections or increase the size of the circuit

breaker to correct trouble. Determine the cause and correct

it before resetting the breaker.

29