Economizer inlet screens – Carrier 50LJ User Manual

Page 22

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Approved oils:

Witco Co............................................................. Suniso 3GS

Texaco, Inc....................................................Capella WF-32

Do not use drained oil and do not use any oil that has

been exposed to the atmosphere.

Unit Voltage

— Be sure power source agrees with the

unit nameplate rating.

Leak Test and Dehydration

— Be sure there are no

refrigerant leaks. All units are shipped with a complete

operating charge of R-22 (Table 1) and should be under

sufficient pressure for leak testing after installation. If there

is no system pressure, add refrigerant until a pressure is

observed and then check for leaks. After leaks are repaired,

dehydrate the system. For leak testing and dehydration

procedures, see Carrier Standard Service Techniques,

Refrigerants, Sections 6 and 7. Do not use the system com

pressors to evacuate the system.

Evaporator Fan, Belt, and Sheaves

— Belts, pul

leys, and sheaves are factory installed. All pulleys are

nonadjustable. See Table 1.

See Table 4 for complete listing of factory and field-

suipplied pulley and belt combinations. See Table 5 for air

quantity limits.

Check the lubrication of fan and motor bearings. Bear

ings are shipped full of grease for corrosion protection and

may run warm temporarily on start-up until the excess grease

has discharged. Check bearing setscrews for tightness. Also

check the tightness of the setscrews on the fan wheel and

on the fan and motor sheaves. Check fan shaft bearing mount

ings for tightness.

Recheck sheave alignment and belt tension. See Adjust

ments section on page 26 for instructions.

Hand-turn the fan to make sure the fan wheel does not

rub on the fan housing. The fan shaft and motor shaft must

be freewheeling before power is applied to the unit.

Following the necessary electrical checks, check for fan

vibration. If excessive vibration occurs, check:

• drive misalignment

• sheaves eccentric or out of balance

• wheel out of balance (replace if necessary)

Check rotation of wheel with arrow on the fan housing.

Check fan speed with a strobe-type tachometer, or use this

formula:

Pan motor rpm x motor sheave pitch diameter (in.)

Rpm

fan sheave pitch diameter (in.)

(Obtain motor rpm from the fan motor nameplate and

read sheave pitch diameters marked on the fan and motor

sheaves.

Example:

Nameplate motor rpm.......................................................1750

Motor sheave pitch diameter (in.)..................................... 6.4

Fan sheave pitch diameter (in.) ........................................12.4

^

„

1750 X 6.4

Fan Rpm =--------- ---------- = 903 rpm

The maximum allowable rpm is 1200. Excessive fan speed

may result in condensate carryover from the evaporator coil,

fan motor overload, or wheel failure. See Table 5 for Air

Quantity Limits.

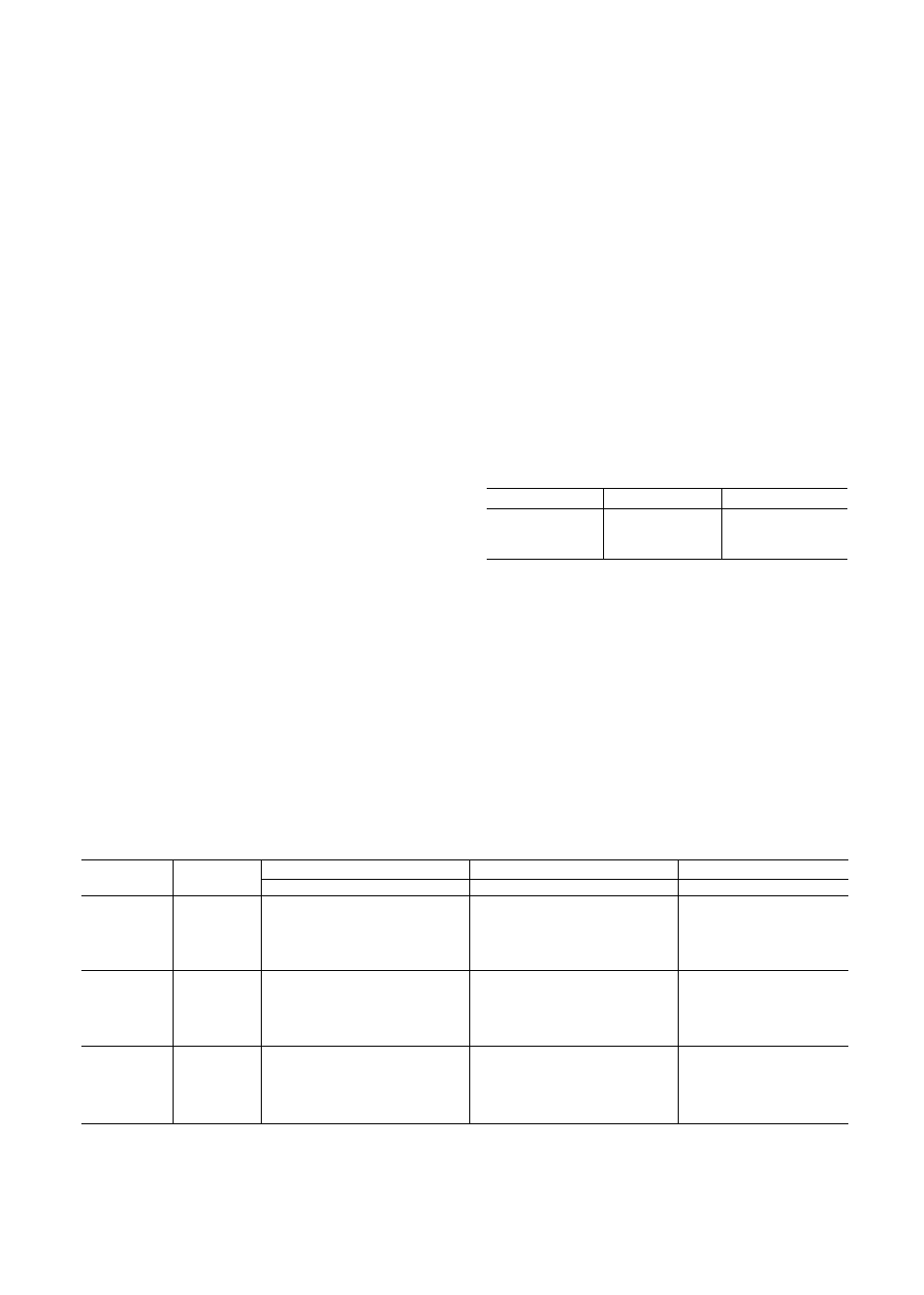

Table 5 — Air Quantity Limits

UNIT

MINIMUM

MAXIMUM

48LJD

6,000

10,000

48UE

6,162‘

10,000

50LJ,LW

6,000

10,000

‘Minimum cfm for heating operation.

Condenser Fans and Motors

— Each unit has 2

condenser fans and motors; these are factory set. See

Fig. 20 for correct location of fan in orifice. Check that

fan propeller rotation is correct; it should be counter

clockwise when facing the fans.

Return-Air Filters

— Check that the correct filters are

installed in the filter rack. See Table 1 for quantities and

sizes. Access is through the door marked FILTER SEC

TION. Do not operate the unit without retum-air filters.

Economizer Inlet Screens —

place before operating the unit.

Check that they are in

Table 4 — Evaporator-Fan Pulley Data

UNIT

FAN

MOTOR PULLEY

BLOWER PULLEY

BELT

RPM

No. Grooves — Type — In.

No. Grooves - Type — In.

No. — Type — Size

780‘

2 - 3V - 4.75

2 - 3V - 10.6

2 - 3V - 850

875

2 - 3V - 5.30

2 - 3V - 10.6

2 - 3V - 850

48U

900*

2 - 3V - 4.12

2 - 3V - 80

2 - 3V - 800

980

2 - 3V - 4.50

2 - 3V - 8.0

2 - 3V - 800

1090

3 - 3V - 5.00

3 - 3V - 80

3 - 3V - 800

1160

3 - 3V - 5 30

3 - 3V - 8.0

3 - 3V - 800

780*

2 - 3V - 4.75

2 - 3V - 10.6

2 - 3V - 560

875

2 - 3V - 5.30

2 - 3V -106

2 - 3V - 560

50LJ

900*

2 - 3V - 4.12

2 - 3V - 8.0

2 - 3V - 500

980

2 - 3V - 4.50

2 - 3V - 8.0

2 - 3V - 500

1090

3 - 3V - 5 00

3 - 3V - 80

3 - 3V - 500

1160

3 - 3V - 5 30

3 - 3V - 8.0

3 - 3V - 500

780*

2 - 3V - 4.75

2 - 3V -106

2 - 3V - 850

875

2 - 3V - 5 30

2 - 3V - 10.6

2 - 3V - 850

50LW

900*

2 - 3V - 4.12

2 - 3V - 80

2 - 3V - 800

980

2 - 3V - 4 50

2 - 3V - 8.0

2 - 3V - 800

1090

3 - 3V - 5.00

3 - 3V - 8.0

3 - 3V - 800

1160

3 - 3V - 5.30

3 - 3V - 8.0

3 - 3V - 800

‘Indicates standard or optional pulley combinations available as shown in Tales la and 1b. All other

combinations are field supplied.

NOTE: The minimum speed with high eiectric heat option is 780 rpm

22