Lubrication, Adjustments – Carrier 50LJ User Manual

Page 26

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

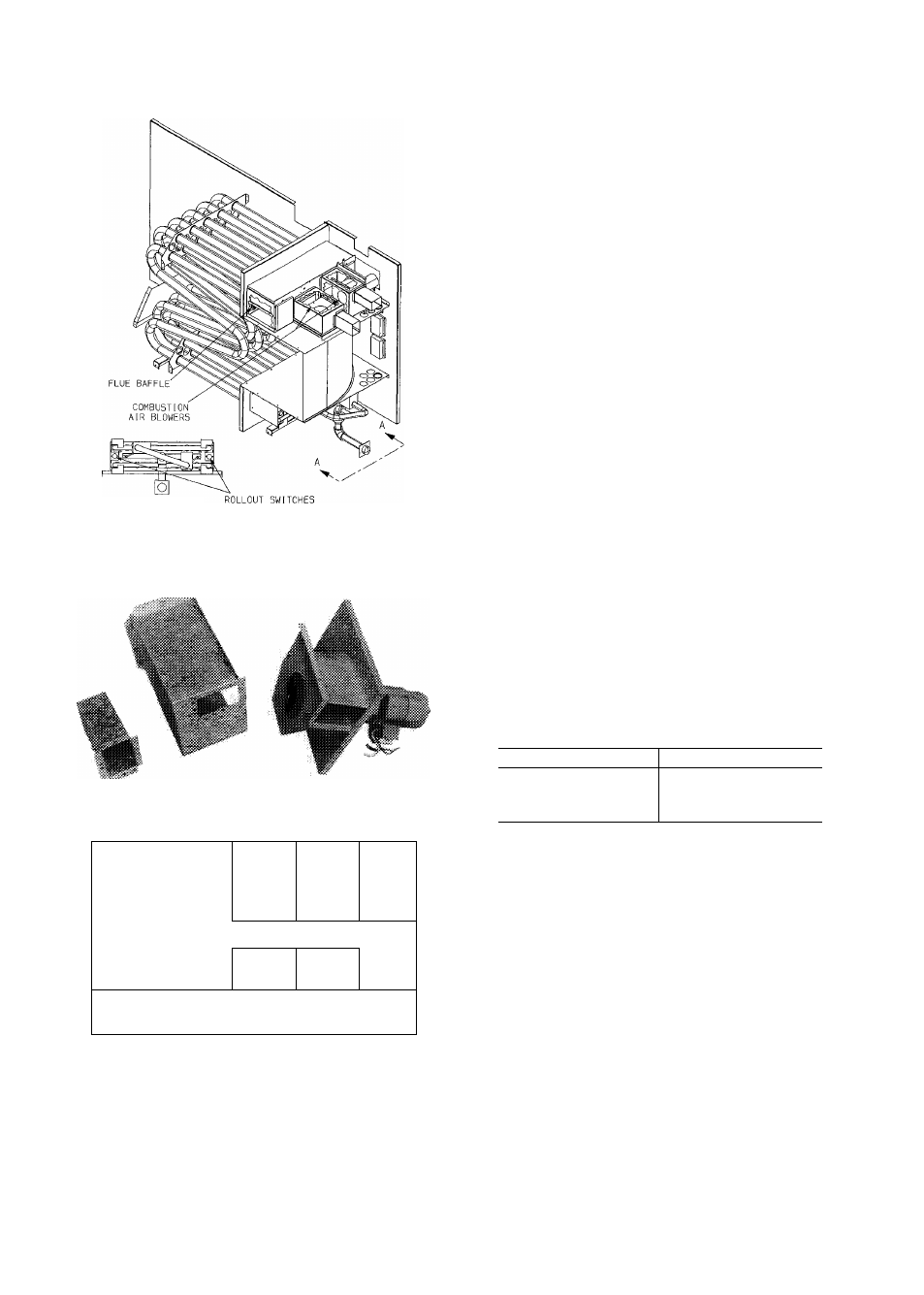

V I E W A - A

BURNER SECTION

Fig. 22 - Gas Section Detaii,

48LJE (High Heat)

Fig. 23 — Combustion Blower Removal

LEGEND

FB

— Fuse Block

FU

- Fuse

HC

- Heater Contactor ELECTRIC HEAT BOX

ECONOMIZER DAMPER MOTOR — On units so equipped,

the economizer motor is located on a bracket in the return-

air section. Access to it is through the panel labeled FIL

TER SECTION on the far end of the unit (when facing

condenser coil).

POWER EXHAUST MOTOR — Remove the power ex

haust hood to gain access to motor.

RETURN-AIR FILTERS — Access to these filters is through

the panel marked FILTER SECTION.

CONDENSER FANS AND FAN MOTORS - Remove the

wire fan guard on top of the unit to gain access to the con

denser fans and motors.

Cleaning

— inspect unit at the beginning of each heat

ing and cooling season and during each season as operating

conditions may require.

Clean condenser coil with a vacuum cleaner, fresh

water, compressed air, or a bristle brush (not wire). Coil

cleaning should be a part of the planned maintenance pro

gram. Clean evaporator coil with a stiff bristle brush (not

wire), vacuum cleaner, or compressed air.

Check and clean condensate drain annually at the start of

the cooling season. In winter, keep drain and traps dry and

protect against freeze-up.

Replace return-air filters at the start of each heating and

cooling season and as often as necessary during each

season, depending on operating conditions. See Tables la

and lb for filter types, quantities, and sizes.

Remove economizer outdoor-air filters from the hoods

by removing the filter retainers. Clean filters with steam or

hot water and mild detergent. Reinstall in hoods after clean

ing. Never replace cleanable filters with disposable filters.

Lubrication

COMPRESSORS — Each compressor is correctly charged

at the factory.

FAN SHAFT BEARINGS — Lubricate fan shaft bearings

at least once a year with suitable bearing grease. Typical

lubricants are given below:

MANUFACTURER

LUBRICANT

Texaco

Regal AFB-2*

Sunoco

Prestige 42

Texaco

Multifak 2

Mobil

Mobilplex EP No. 1

Fig. 24 — Typical Electric Heat Control Box

Component Arrangement

’Preferred lubricant because it contains rust and oxidation

inhibitors.

FAN MOTOR BEARINGS — The condenser-fan motors

and the evaporator-fan motor(s) have sealed bearings, so no

field lubrication is required.

DOOR HINGES — The control box door hinges should be

lubricated at least once a year.

Adjustments

EVAPORATOR-FAN MOTOR PLATE — Adjust using a

'Vie-in. wrench on the bolts shown in Fig. 25 and 26. Turn

the bolts counterclockwise to move the motor mounting plate

toward the fan and loosen the belts; turn clockwise to move

the plate away from the wheel and tighten the belts. Make

the same number of turns to each bolt.

I

26