Start-up, Installation locations for flue hood assemblies, Fig. 19 — flue hood details – Carrier 50LJ User Manual

Page 21

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

i(f

Gas Piping

— Unit is equipped for use with natural gas

only. Installation must conform to local building codes, or

in the absence of local codes, with the NFGC (National

Fuel Gas Code), ANSI (American National Standards

Institute) Z223.1-1984.

A '/sin. NPT tapping plug, accessible for test gage con

nection, must be field installed immediately upstream of

gas supply connection to unit. See Fig. 18.

Natural gas pressure at unit gas connection must not be

less than 5 in. wg or greater than 14 in. wg.

Size gas supply piping for 0.5 in. wg maximum pressure

drop. Do not use supply pipe smaller than unit gas

connection.

A

CAUTION

Disconnect gas piping from unit when leak testing at

pressures greater than 0.5 psig. Pressures greater than

0.5 psig will cause gas valve damage resulting in a haz

ardous condition. If gas valve is subjected to pressure

greater than 0.5 psig, it must be replaced.

UNION (FOR SERVICING)

*NPT plug is field supplied.

NOTE: Follow all local codes.

Fig. 18 - Gas Piping Detaiis

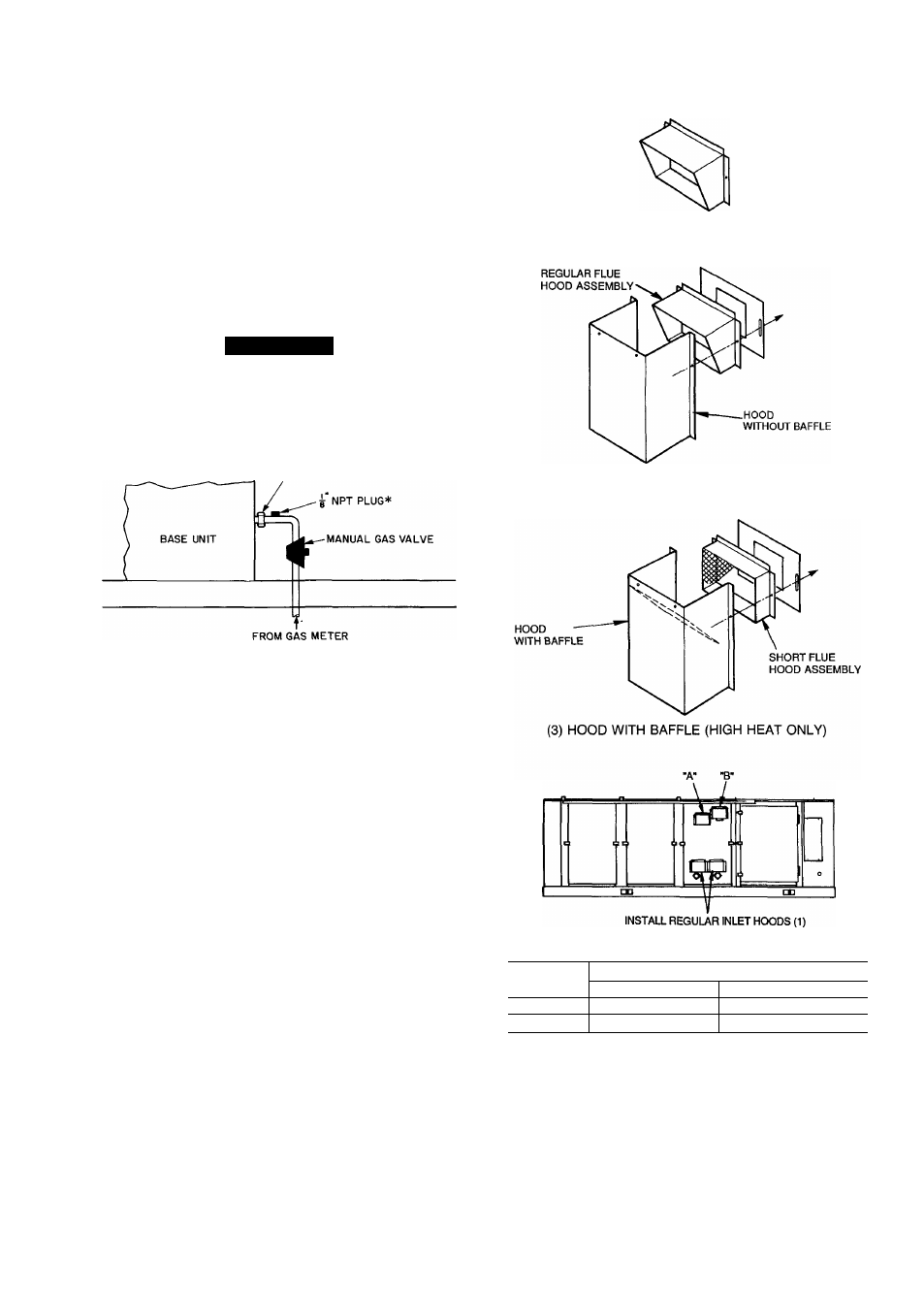

Installing Flue/lnlet Hoods

— The flue/inlet hoods

are shipped in a bag taped to the basepan under the unit

fan. Remove the shipping block-offs and install hoods as

shown in Fig. 5a and 19. Use RTV sealant to provide rain

proof seal between hoods and door.

START-UP

Unit Preparation

— Check to see that unit has been

installed in accordance with these Installation Instructions

and all applicable codes.

Interhal Wiring

— Check all electrical connections in

the unit control box; tighten as required.

Refrigerant Service Ports

— Each unit system has

3 Schrader-type service ports, one on the suction line, one

on the liquid line, and one on the compressor discharge line.

Be sure that caps on the ports are tight.

Crankcase Heaters

— The crankcase heaters must be

firmly locked onto the compressors. The crankcase heaters

are energized when there is power to the unit. Crankcase

heaters must be energized for at least 24 hours prior to unit

start-up in order to remove liquid refrigerant from the com

pressor crankcase.

Compressor Oil

— All units are factory charged with

oil. The initial charge is 128 oz. The recharge is 124 oz.

See Carrier Standard Service Techniques, Refrigerants, for

procedures to add or remove oil.

(1) REGULAR INLET HOOD

(2) HOOD WITHOUT BAFFLE (LOW HEAT ONLY)

Installation Locations for Flue Hood Assemblies

UNIT

LOCATION

TYPE

“A”

“B”

High Heat

Hood With Baffle (3)

Hood With Baffle (3)

Low Heat

-

Hood Without Baffle (2)

NOTE: Numbers in ( ) refer to type of hood to install in location

indicated.

Fig. 19 — Flue Hood Details

If it is necessary to remove oil, do not remove any oil

until the compressor crankcase heater has been ON for at

least 24 hours. When additional oil or a complete charge is

needed, use only Carrier-approved compressor oil.

21