Complete c and deluxe d board system test, Test mode, Retry mode – Carrier 50PEC09-18 User Manual

Page 33: Aquazone™ deluxe d control led indica- tors

33

immediately when the Cooling Stage 1 demand is removed.

The control reverts to Standby mode. The RV relay remains on

until there is a heating demand. If there is a master/slave or

dual compressor application, all compressor relays and related

functions will track with their associated DIP switch 2 on S1.

COOLING STAGE 2 — In Cooling Stage 2 mode, the fan

enable, compressor and RV relays remain on. The fan speed re-

lay is turned on immediately and turned off once the Cooling

Stage 2 demand is removed. The control reverts to Cooling

Stage 1 mode. If there is a master/slave or dual compressor

application, all compressor relays and related functions will

track with their associated DIP switch 2 on S1.

NIGHT LOW LIMIT (NLL) STAGED HEATING — In NLL

staged Heating mode, the override (OVR) input becomes

active and is recognized as a call for heating and the control

will immediately go into a Heating Stage 1 mode. With an

additional 30 minutes of NLL demand, the control will go into

Heating Stage 2 mode. With another additional 30 minutes of

NLL demand, the control will go into Heating Stage 3 mode.

COMPLETE C AND DELUXE D BOARD

SYSTEM TEST

System testing provides the ability to check the control

operation. The control enters a 20-minute Test mode by

momentarily shorting the test pins. All time delays are reduced

by a factor of 15.

Test Mode —

To enter Test mode on Complete C or

Deluxe D controls, cycle the fan 3 times within 60 seconds.

The LED (light-emitting diode) will flash a code representing

the last fault when entering the Test mode. The alarm relay will

also power on and off during Test mode. See Tables 12-14. To

exit Test mode, short the terminals for 3 seconds or cycle the

power 3 times within 60 seconds.

NOTE: The Deluxe D control has a flashing code and alarm

relay cycling code that will both have the same numerical

label. For example, flashing code 1 will have an alarm relay

cycling code 1. Code 1 indicates the control has not faulted

since the last power-off to power-on sequence.

Retry Mode —

In Retry mode, the status LED will start to

flash slowly to signal that the control is trying to recover from an

input fault. The control will stage off the outputs and try to again

satisfy the thermostat used to terminal Y. Once the thermostat in-

put calls are satisfied, the control will continue normal operation.

NOTE: If 3 consecutive faults occur without satisfying the

thermostat input call to terminal Y, the control will go into

lockout mode. The last fault causing the lockout is stored in

memory and can be viewed by entering Test mode.

Aquazone™ Deluxe D Control LED Indica-

tors —

There are 3 LED indicators on the Deluxe D control:

STATUS LED — Status LED indicates the current status or

mode of the Deluxe D control. The Status LED light is green.

TEST LED — Test LED will be activated any time the De-

luxe D control is in Test mode. The Test LED light is yellow.

FAULT LED — Fault LED light is red. The fault LED will

always flash a code representing the last fault in memory. If

there is no fault in memory, the fault LED will flash code 1 and

appear as 1 fast flash alternating with a 10-second pause. See

Table 14.

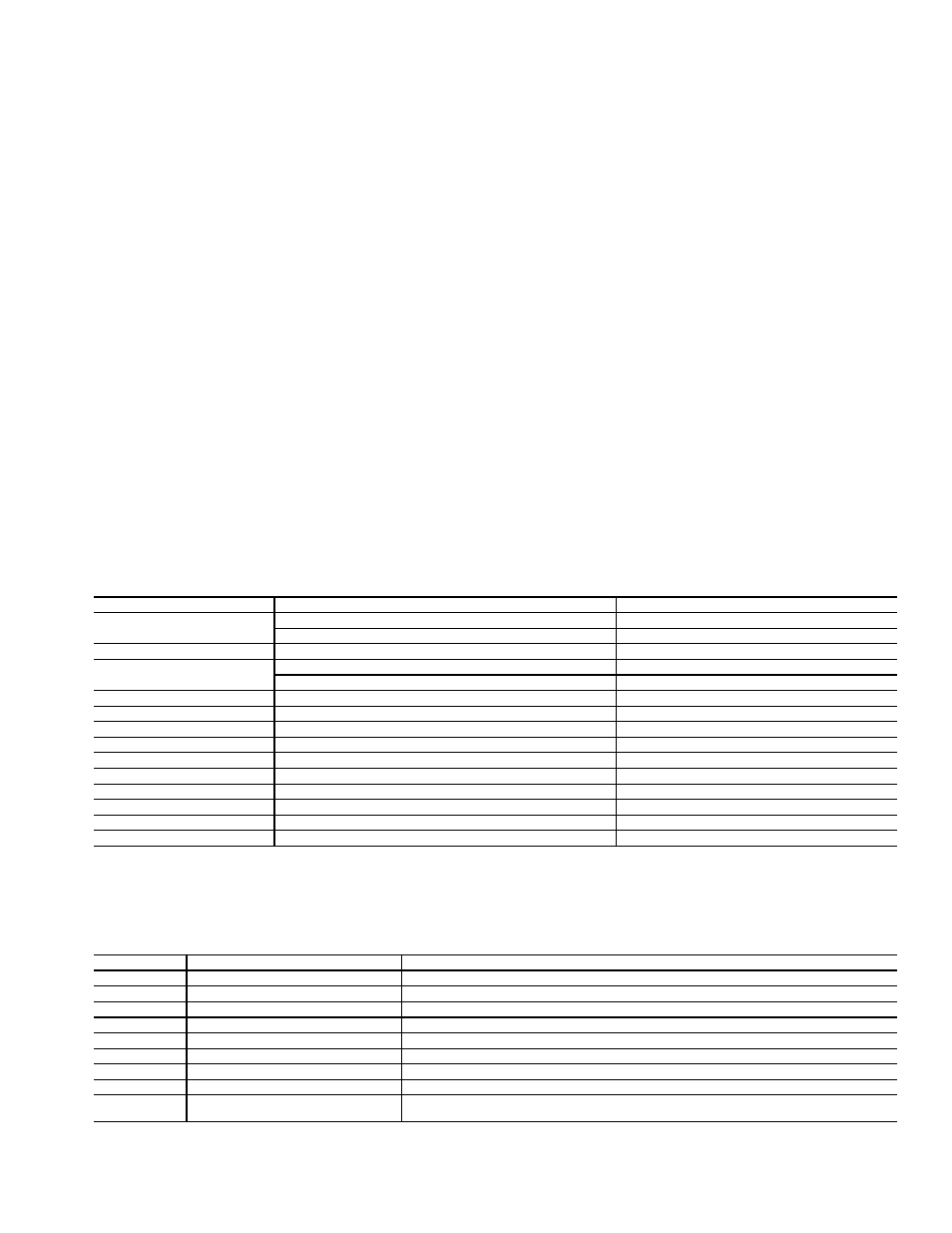

Table 12 — Complete C Control Current LED Status and Alarm Relay Operations

LEGEND

NOTES:

1. Slow flash is 1 flash every 2 seconds.

2. Fast flash is 2 flashes every 1 second.

3. EXAMPLE: “Flashing Code 2” is represented by 2 fast flashes followed

by a 10-second pause. This sequence will repeat continually until the

fault is cleared.

Table 13 — Complete C Control LED Code and Fault Descriptions

LEGEND

LED STATUS

DESCRIPTION OF OPERATION

ALARM RELAY

On

Normal Mode

Open

Normal Mode with PM Warning

Cycle (Closed 5 sec, Open 25 sec)

Off

Complete C Control is non-functional

Open

Slow Flash

Fault Retry

Open

Over/Under Voltage Shutdown

Open (Closed after 15 minutes)

Fast Flash

Lockout

Closed

Flashing Code 1

Test Mode — No fault in memory

Cycling Code 1

Flashing Code 2

Test Mode — HP Fault in memory

Cycling Code 2

Flashing Code 3

Test Mode — LP Fault in memory

Cycling Code 3

Flashing Code 4

Test Mode — FP1 Fault in memory

Cycling Code 4

Flashing Code 5

Test Mode — FP2 Fault in memory

Cycling Code 5

Flashing Code 6

Test Mode — CO Fault in memory

Cycling Code 6

Flashing Code 7

Test Mode — Over/Under shutdown in memory

Cycling Code 7

Flashing Code 8

Test Mode — PM in memory

Cycling Code 8

Flashing Code 9

Test Mode — FP1/FP2 swapped fault in memory

Cycling Code 9

CO —

Condensate Overflow

LED —

Light-Emitting Diode

FP

—

Freeze Protection

LP

—

Low Pressure

HP

—

High Pressure

PM

—

Performance Monitor

LED CODE

FAULT

DESCRIPTION

1

No fault in memory

There has been no fault since the last power-off to power-on sequence

2

High-Pressure Switch

HP open instantly

3

Low-Pressure Switch

LP open for 30 continuous seconds before or during a call (bypassed for first 60 seconds)

4

Freeze Protection Coax — FP1

FP1 below temp limit for 30 continuous seconds (bypassed for first 60 seconds of operation)

5

Freeze Protection Air Coil — FP2

FP2 below temp limit for 30 continuous seconds (bypassed for first 60 seconds of operation)

6

Condensate overflow

Sensor overflow (grounded) for 30 continuous seconds

7 (Autoreset)

Over/Under Voltage Shutdown

"R" power supply is <19-vac or >30-vac

8

PM Warning

Performance monitor Warning has occurred.

9

FP1 and FP2 Thermistors are swapped

FP1 temperature is higher than FP2 in heating/test mode, or FP2 temperature is higher than FP1 in

cooling/test mode.

FP

— Freeze Protection

LP

— Low Pressure

HP

— High Pressure

PM — Performance Monitor

LED — Light-Emitting Diode