Carrier 50PEC09-18 User Manual

Page 27

27

PRE-START-UP

System Cleaning and Flushing —

Cleaning and

flushing the unit and system is the single most important step to

ensure proper start-up and continued efficient operation of the

system.

Follow the instructions below to properly clean and flush

the system:

1. Verify that electrical power to the units is disconnected,

and that the circulation pump is deenergized.

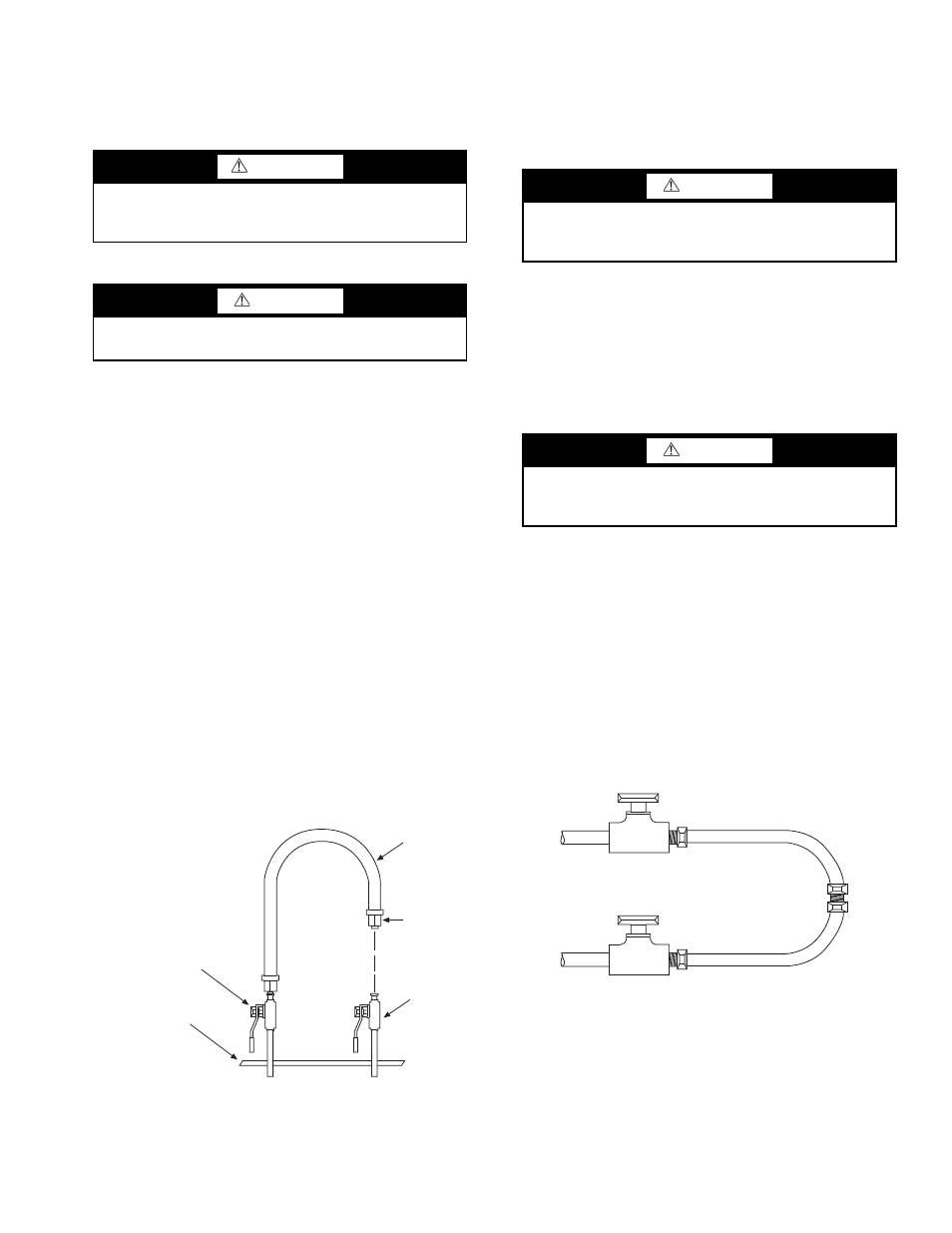

2. Connect the supply hose directly to the return riser valve.

Use a single length of flexible hose, as shown in Fig. 29.

NOTE: If the length of hose is too short (i.e., the resulting con-

nection would exceed the minimum bend radius of the hose),

substitute two lengths of flexible hose joined together with a

field-supplied, standard NPT coupling and the flare-fitting-to-

pipe adapters provided with the hose kit (Fig. 29).

3. Open all air vents. Fill the system with water. Do not al-

low system to overflow. Bleed all air from the system.

Check the system for leaks and repair appropriately.

4. Check and adjust the water and air level in the expansion

tank.

5. Verify all strainers are in place. Start the pumps, and sys-

tematically check each vent to ensure all air is bled from

the system.

6. Verify make-up water is available. Adjust make-up water

appropriately to replace the air that was bled from the

system. Pressure test and inspect the system for leaks and

make any necessary repairs. Check and adjust the water

and air level in the expansion tank.

7. Open a drain at the lowest point in the system. Adjust the

make-up water replacement rate to equal the rate of bleed.

Continue to bleed the system until the water appears

clean or for at least three hours, whichever is longest;

then, completely drain the system.

8. Refill the system with clean, chemically treated water.

Since water varies for each locality, contact a local water

treatment company for the correct treatment chemicals to

use in the area. Set the boiler to raise the loop temperature

to approximately 29.4 C.

.

Circulate the solution for a minimum of 8 to 24 hours. At

the end of this period, shut off the circulating pump and

drain the solution. Repeat system cleaning as necessary.

9. When the cleaning process is complete, remove the short-

circuited hoses. Connect the hoses to the proper supply

and return connections on each unit. Refill the system and

bleed off all air.

10. Test the system pH with litmus paper. The system water

should be slightly alkaline (pH 7.0 to 8.5). Add chemi-

cals, as appropriate, to maintain acidity levels.

11. When the system is successfully cleaned, flushed, refilled

and bled, check the main system panels, safety cutouts

and alarms. Set the controls to properly maintain loop

temperatures.

System Checkout —

When the installation is complete

and the system is cleaned and flushed, follow the system

checkout procedure outlined below.

1. Voltage: Ensure voltage is within the utilization range

specifications of the unit compressor and fan motor.

2. System Water Temperature: Ensure temperature is within

an acceptable range shown in Table 4. (When conducting

this check, also verify proper heating and cooling set

points.)

WARNING

To prevent injury or death due to electrical shock or contact

with moving parts, open unit disconnect before servicing

unit.

CAUTION

Do not flush system through the unit. Damage to unit could

result.

CAUTION

To avoid possible damage to piping systems constructed of

plastic piping DO NOT allow loop temperature to exceed

43.3 C.

CAUTION

DO NOT use “Stop-Leak” or any similar chemical agent in

this system. Addition of these chemicals to the loop water

will foul the system and will inhibit unit operation.

1/2” Flexible Hose

Brass Adapter

(1/2” MPT x 1/2”

Male Flare)

Supply Valve

Floor Line

Return Valve

Fig. 29 — Temporary Connection for Flushing System Piping

NOTE: Use standard coupling (field-supplied)

and hose adapters to join 2 hoses.