Carrier 50PEC09-18 User Manual

Page 31

31

AHRI/ISO/ASHRAE Standard 13256-1 rating test, for initial

start-up in winter.

Unit Start-Up

1. Turn the thermostat fan position to “ON”. Blower should

start.

2. Balance air flow at registers.

3. Adjust all valves to their full open positions. Turn on the

line power to all heat pumps.

4. Room temperature should be within the minimum and

maximum ranges of Table 4. During start-up checks, loop

water temperature entering the heat pump should be be-

tween 16 C and 35 C.

5. Two factors determine the operating limits of Carrier heat

pumps, return air temperature and water temperature.

When any one of these factors is at a minimum or maxi-

mum level, the other factor must be at normal level to en-

sure proper unit operation.

a. Adjust the unit thermostat to the warmest setting.

Place the thermostat mode switch in the “COOL”

position. Slowly reduce thermostat setting until the

compressor activates.

b. Check for cool air delivery at the unit grille within

a few minutes after the unit has begun to operate.

Units have a five minute time delay in the control

circuit that can be eliminated on the control board

if needed.

c. Check the elevation and cleanliness of the conden-

sate lines. Dripping may be a sign of a blocked

line. Check that the condensate trap is filled to pro-

vide a water seal.

d. Check the temperature of both entering and leaving

water. See Table 8. If temperature is within range,

proceed with the test. If temperature is outside the

range, check refrigerant pressures.

e. Check air temperature drop across the air coil

when compressor is operating. Air temperature

drop should be between 8° C and 14° C.

f. Turn thermostat to “OFF” position. A hissing noise

indicates proper functioning of the reversing valve.

6. Allow five (5) minutes between tests for pressure to

equalize before beginning heating test.

a. Adjust the thermostat to the lowest setting. Place

the thermostat mode switch in the “HEAT” posi-

tion.

b. Slowly raise the thermostat to a higher temperature

until the compressor activates.

c. Check for warm air delivery within a few minutes

after the unit has begun to operate.

d. Refer to Table 8. Check the temperature of both

entering and leaving water. If temperature is within

range, proceed with the test. If temperature is out-

side the range, check refrigerant pressures.

e. Check air temperature rise across the air coil when

compressor is operating. Air temperature rise

should be between 11° C and 17° C.

f. Check for vibration, noise, and water leaks.

7. If unit fails to operate, perform troubleshooting analysis

(see troubleshooting section). If the check described fails

to reveal the problem and the unit still does not operate,

contact a trained service technician to ensure proper diag-

nosis and repair of the equipment.

When testing is complete, set system to maintain desired

comfort level.

Flow Regulation —

Flow regulation can be accom-

plished by two methods. Most water control valves have a

built-in flow adjustment valve. Determine the flow rate by

measuring the pressure drop through the unit heat exchanger.

See Table 9. Adjust the water control valve until a flow of 2.0

to 3.9 L/m per kW cooling is achieved. Since the pressure

constantly varies, two pressure gages may be needed.

An alternative method for regulating flow is to install a flow

control device. These devices are typically an orifice of plastic

material mounted on the outlet of the water control valve,

designed to allow a specified flow rate. Occasionally these

valves produce a velocity noise that can be reduced by

applying some back pressure. To accomplish this, slightly close

the leaving isolation valve of the water regulating device.

Antifreeze —

In areas where entering loop temperatures

drop below 4.4 C or where piping will be routed through areas

subject to freezing, antifreeze is needed.

Alcohols and glycols are commonly used as antifreeze

agents. Freeze protection should be maintained to 8.3° C below

the lowest expected entering loop temperature. For example, if

the lowest expected entering loop temperature is –1.1 C, the

leaving loop temperature would be –5.6 to –3.9 C. Therefore,

the freeze protection should be at –9.4 C (–1.1 C – 8.3 C =

–9.4 C).

Calculate the total volume of fluid in the piping system. See

Table 10. Use the percentage by volume in Table 11 to deter-

mine the amount of antifreeze to use. Antifreeze concentration

should be checked from a well mixed sample using a hydrome-

ter to measure specific gravity.

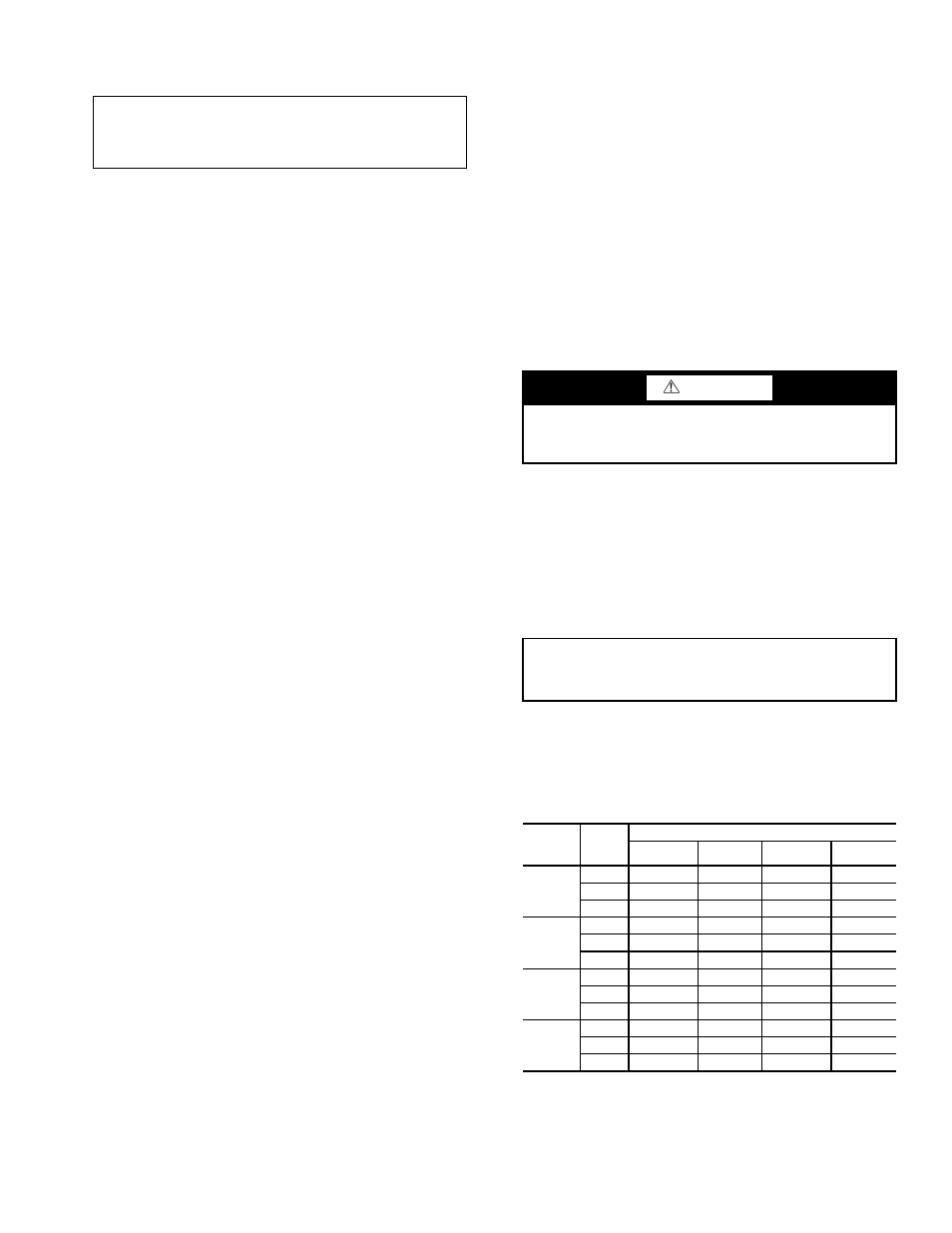

Table 9 — Coaxial Water Pressure Drop

IMPORTANT: These operating limits are not normal or

continuous operating conditions. It is assumed that such a

start-up is for the purpose of bringing the building space up

to occupancy temperature.

CAUTION

DO NOT use “Stop Leak” or any similar chemical agent in

this system. Addition of these chemicals to the loop water

will foul the system and inhibit unit operation.

IMPORTANT: All alcohols should be pre-mixed and

pumped from a reservoir outside of the building or intro-

duced under water level to prevent alcohols from fuming.

50PEC

UNIT

SIZE

L/m

PRESSURE DROP (kPa)

-1 C

10 C

21 C

32 C

09

4.2

11.0

8.3

6.9

6.2

6.1

17.9

15.2

13.8

13.1

8.7

31.0

26.2

24.1

20.7

12

5.7

14.5

12.4

10.3

9.0

8.7

31.0

26.2

24.1

20.7

11.4

46.9

40.0

33.8

31.0

15

7.2

10.3

6.9

6.2

5.5

10.6

20.7

15.8

13.8

11.7

14.0

32.4

26.9

22.7

20.0

18

8.7

15.2

12.4

10.3

9.0

12.9

30.3

26.2

23.4

20.7

17.1

47.5

41.3

35.8

33.1