Hepa filter and gas lines, Storage of the sco6ad incubator, Door and electrical components – Shellab SCO6AD User Manual

Page 41: E 41), User maintenance (continued), Hepa, Sco6ad

41 |

P a g e

USER MAINTENANCE (CONTINUED)

HEPA

F

ILTER AND

G

AS

L

INES

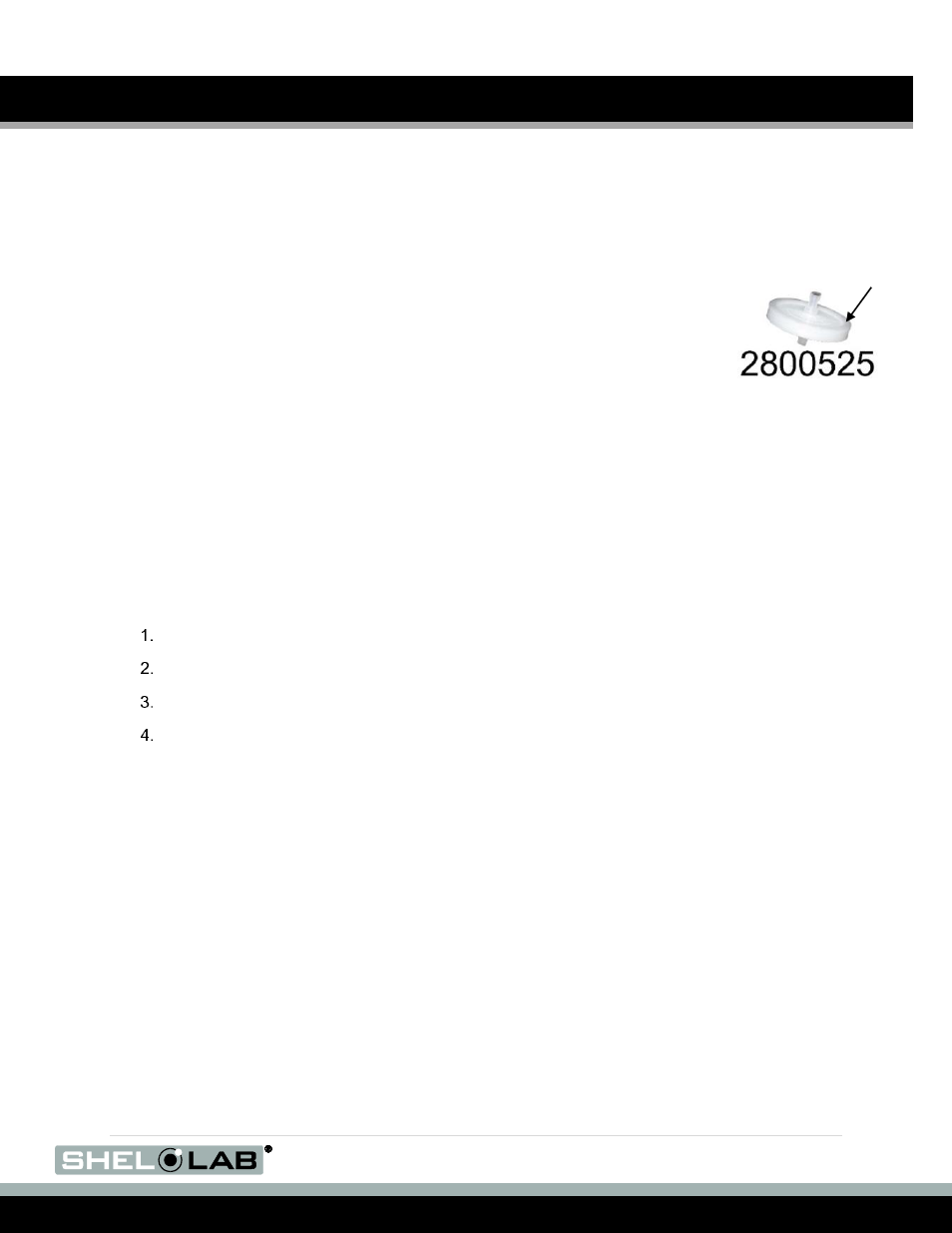

Sheldon Manufacturing recommends replacing the external in-line gas HEPA filter once

per year, or more often when the filter is noticeably discolored. The filter is directional,

and must be installed facing in the correct direction. The word “IN” is stamped on the rim

of the filter assembly on the side that faces toward the gas source.

Gas lines should be replaced when cracking, brittleness, permanent kinking, or other signs of

damage are present. Please see the

S

TORAGE OF THE

SCO6AD

I

NCUBATOR

Perform the following steps if the incubator will be out of use for more than 24 hours to prevent

microbiological contamination such as, fungus or mold. Disinfect the unit before drying if the

chamber and shelving have been exposed to pathogenic microorganisms, or if required by your

laboratory protocol.

Depower the incubator.

Empty and dry the humidity pan.

Use a soft cloth to dry the chamber surfaces.

The incubator will not need to be recalibrated for temperature and CO

2

if it is returned to

operation in the same workspace environment it was last calibrated in

— unless changes

have been made in the ambient conditions.

D

OOR AND

E

LECTRICAL

C

OMPONENTS

Inspect the door latch, trim, catch, and gasket for signs of deterioration every six months. Failure to

maintain the integrity of the door components shortens the lifespan of the incubator.

Electrical components do not require maintenance. If the SCO6AD fails to operate as specified,

please contact your Shel Lab dealer or distributor or Shel Lab Technical Support for assistance.

“IN”