Operation (continued), Atmosphere, Alarms – Shellab SCO6AD User Manual

Page 20

20 |

P a g e

OPERATION (CONTINUED)

CO

2

Atmosphere

The SCO6AD controls the concentration of CO

2

in the incubation chamber atmosphere by

operating an internal electric gas pump connected to the gas input line. The motor pulses CO

2

into

the chamber air stream when deviations from the user-programed CO

2

set point are detected. The

incubator monitors the chamber CO

2

concentration with an infrared sensor in a recirculation box

above the main chamber. The sensor operates on the principle that a specific frequency set of

infrared light is absorbed by CO

2

. The more CO

2

present in the air stream from the chamber, the

more of this band of infrared is absorbed. The sensor is only sensitive to CO

2

, so the measurement

accuracy (

±0.1%) is consistent, regardless of the presence of other gasses. The incubator can

maintain a CO

2

concentration level of 0

– 20% in the chamber, and has a recovery time of less than

5 minutes to restore the concentration level after the inner chamber door has been closed.

The SCO6AD employs proportional-integral-derivative analytic feedback-loop functions when

measuring and controlling the CO

2

concentration. The length of gas injections is proportional to the

difference between the measured concentration and the set point. The frequency of injections is

derived from the rate of change in the difference. Integrator feedback slows the rate of injection as

the concentration approaches the set point, which helps prevent overshoots. During normal

operations CO

2

injections take place in small bursts to correct for deviations of 0.1%. Typically, gas

injections will be long when first setting up the unit for use after installation, and frequent when

recovering from door openings.

The SCO6AD requires periodic calibrations to verify that it is accurately measuring and displaying

the CO

2

level in the chamber. If a measurement error is detected during a CO

2

calibration

procedure (see page 30), the CO

2

display can be calibrated to the actual concentration in the

chamber by placing the display in its calibration mode. Gas calibrations require a gas-analyzer

reference device capable of measuring CO

2

concentrations to at least 0.1% accuracy.

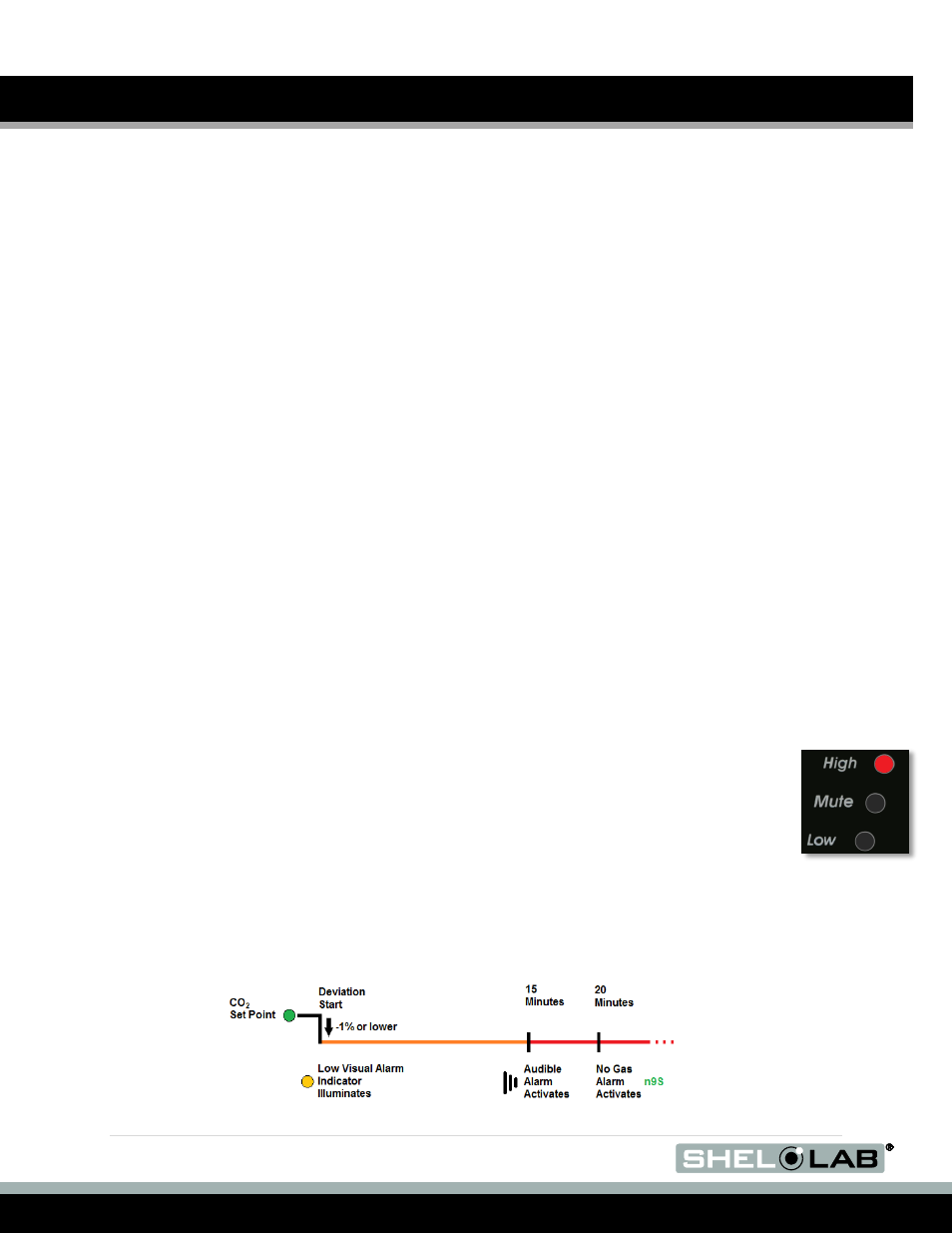

Alarms

The SCO6AD is provided with high and low alarms for temperature and CO

2

deviations. The

alarms have visual indicators and audible components. The temperature alarms thresholds are

deviations of 1

°C or greater from the set point. The CO

2

deviation alarms trip points are

deviations of 1% or greater from the gas concentration set point. There is a 15 minute delay for

the sounding of the low deviation audible alarms to prevent activations when the chamber doors

are opened for brief periods. If the low CO

2

deviation indicator is lit for 20 minutes, a visual No

Gas Supply alarm will activate and show in the CO

2

display as “ngS”.

All audible deviation alarms can be muted, but the visual indicators will remain illuminated for the

duration of a deviation. See the

Muting the Audible Temperature Alarm

entry on page 28 and the

entry on page 32.