Blower performance tables, Table legend – Reznor P6SP Unit Installation Manual User Manual

Page 23

23

unit Model #

Motor

Hp

E.s.P. range

(in-Wg)

Blower rpm

range (DF)

Down-flow

Kit

Blower rpm

range (HF)

Horizontal

Kit

-072C

1.5 Hp

0.8 - 1.6

931 - 1189

920609

926 - 1159

920609

-072D

920560

920560

-090(C/D)a

2 Hp

0.1 - 1.7

884 - 1216

921481

874 - 1209

921481

-120(C/D)a

2 Hp

0.1 - 1.4

650 - 911

921645

659 - 919

921645

notE: Refer to the P6SP TSL or Accessory Kit Installation Instructions for actual blower charts

table 4. P6sP series alternate accessory Blower Drives

Blower Performance tables

This equipment is outfitted with a belt driven blower assembly in order to accommodate a large variety of duct

configurations and airflow selections. The blower has been factory inspected for proper alignment, operation and

rotational direction prior to the drive motor being situated in the shipping position. The blower drive belt is located

with these instructions and must be installed by the service technician. For a more detailed explanation of belt driven

blower drives and the operation of their components please refer to any of the installation instructions listed below

for the high static drive kits.

The factory standard drive installed in these units has been set to deliver 400 Cfm/ton at an External Static Pressure

(ESP) of 0.25-0.30 in-Wg. Tables 5-10 show the full blower curves of these drive configurations and can be utilized

to easily set the adjustable motor sheave for alternate configurations. Refer to the Legend below for a description

of the table information. Once a sheave setting has been made, always inspect the blower amp draw to ensure that

it is less then the service factor amps listed on the motor. For systems that include a large number of accessories

or have very restrictive duct systems, alternate drive kits are available – refer to table 4 below for the applicable

kits. The full blower curves for the HSD kits can be found in the applicable kit installation instructions or in the unit

technical service literature.

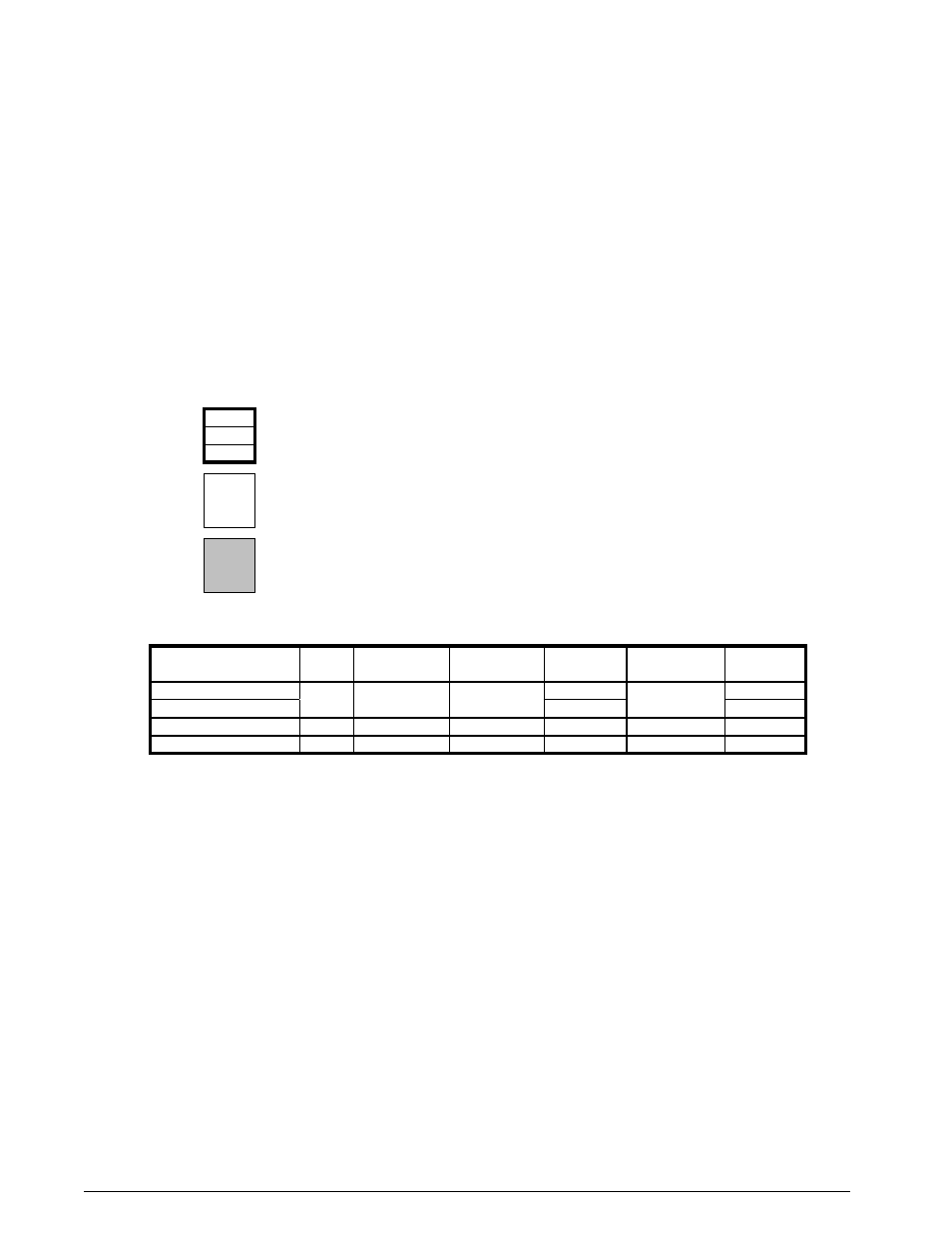

3862

1159

Indicates a recommended unit operational point

3.03

3493

Indicates an allowable setting that is not recommended for unit operation

†

† These operational points should be carefully examined by the installer for proper unit setup and heater operation if used.

1017

2.07

Indicates a setting that is not permitted for unit operation

table

legend