Great Planes Super Skybolt 60 Kit - GPMA0170 User Manual

Page 63

Small Nylon

Control Horn

D 2 If you built your Skybolt with four ailerons,

hold the six small nylon control horns

(NYLON03) on the top and bottom wing ailerons in

the positions shown on the plan, and mark the

mounting hole locations Drill 3/32" holes at these

locations. The slave strut horns should be cut off

as shown on the I-strut detail drawing.

D 3. Harden the balsa in the area of all the

control horns by poking several holes with a pin

(on both sides of the control s u r f a c e ) , then

applying thin CA glue. Allow the glue to soak in

and cure. Then sand the surfaces smooth.

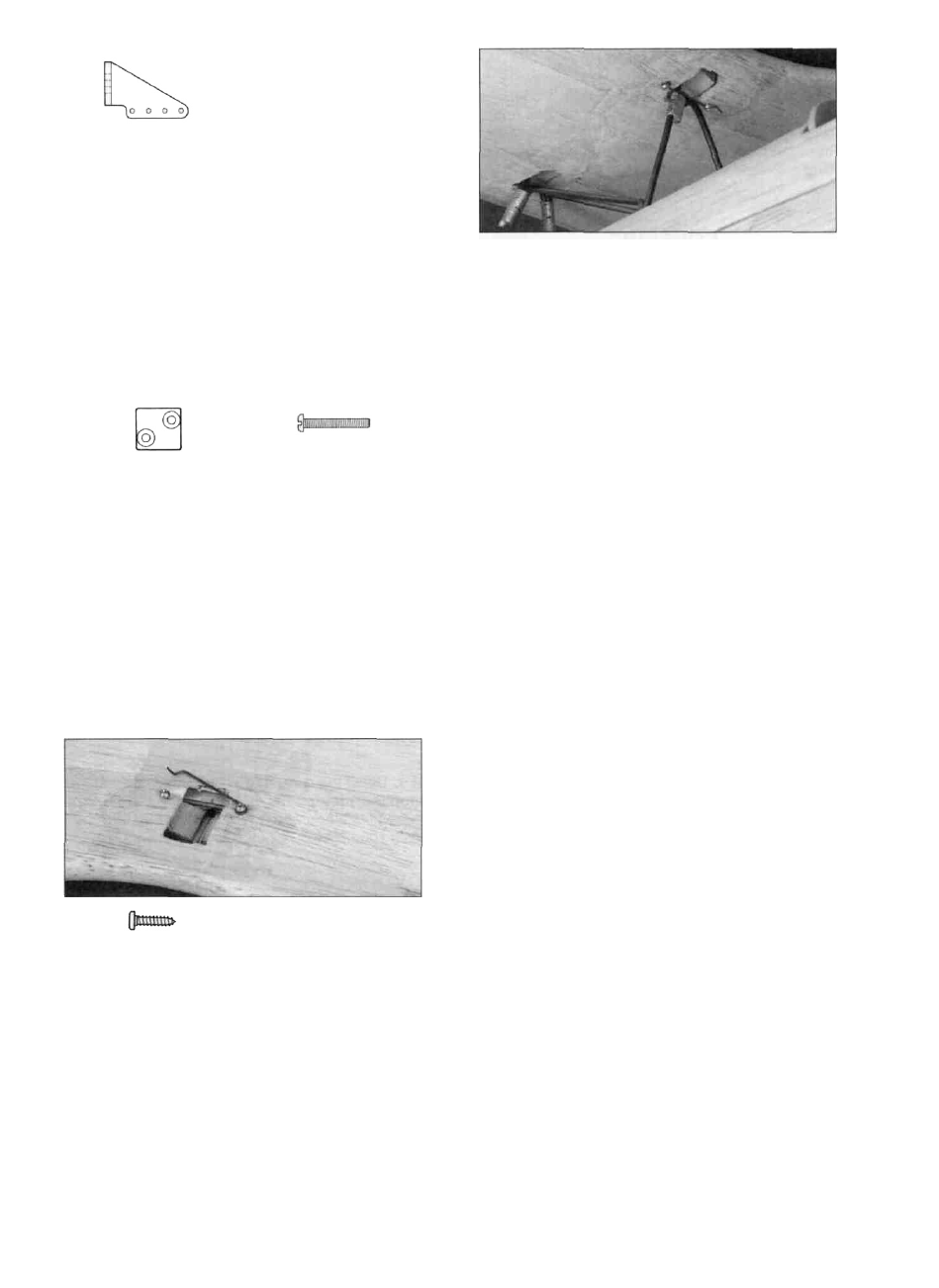

D 2 Install the top wing, and make sure it slides

all the way onto the struts Rotate the locking wire

into place against the cabane wire. Mark where the

second screw should be inserted Set it up so you

have to push the wire forward and over the head of

the second screw to be able to remove it. The

head of the second screw should hold the locking

wire in place during flight The locking wire can be

bent slightly, if needed, to make things fit right.

Nut Plate

2-56 x 5/8" Machine

Screw

D 4. Test mount all the control horns with 2-56 x

5/8" machine screws and the nylon nutplates

which were attached to the horns. Remove the

control horns until after the plane is covered.

BALANCE THE AIRPLANE

LATERALLY

MAKE THE TOP WING LOCK

#2 x 3/8" Screw

SPECIAL NOTE: Do not confuse this

procedure with "checking the C.G." or

"balancing the airplane fore and aft."

Thai very important step will be covered

later in the manual.

Now that you have the basic airframe nearly

completed, this is a good time to balance the

airplane laterally (side-to-side) Here is how to do it:

D 1. Temporarily attach the wing, tail feathers and

the engine (with muffler) to the fuselage.

D 1. Drill a 1/16" hole for the top wing lock

screw. It should be positioned 1/4" behind the aft

edge of the rear top plate and 1/8" outboard of the

T1 rib. Refer to the plans to help you position it.

The main thing is to make sure the screw anchors

into the basswood screw block. Bend the top wing

locking wire (WBNT185) to match the drawing on

the plan Screw it in place with a #2 x 3/8 screw.

Bend the last 3/16" of the wire up away from the

surface of the wing so it will be easier to grab.

D 2. With the wing level, lift the model by the

engine propeller shaft and at the centerline of the fin

(this may require two people). Do this several times.

D 3. If one wing always drops when you lift, it

means that side is heavy. Balance the airplane by

gluing weight to the inside of the other wing tip.

NOTE: An airplane that has been laterally balanced

will track better in loops and other maneuvers.

- 6 3 -