Great Planes Super Skybolt 60 Kit - GPMA0170 User Manual

Page 49

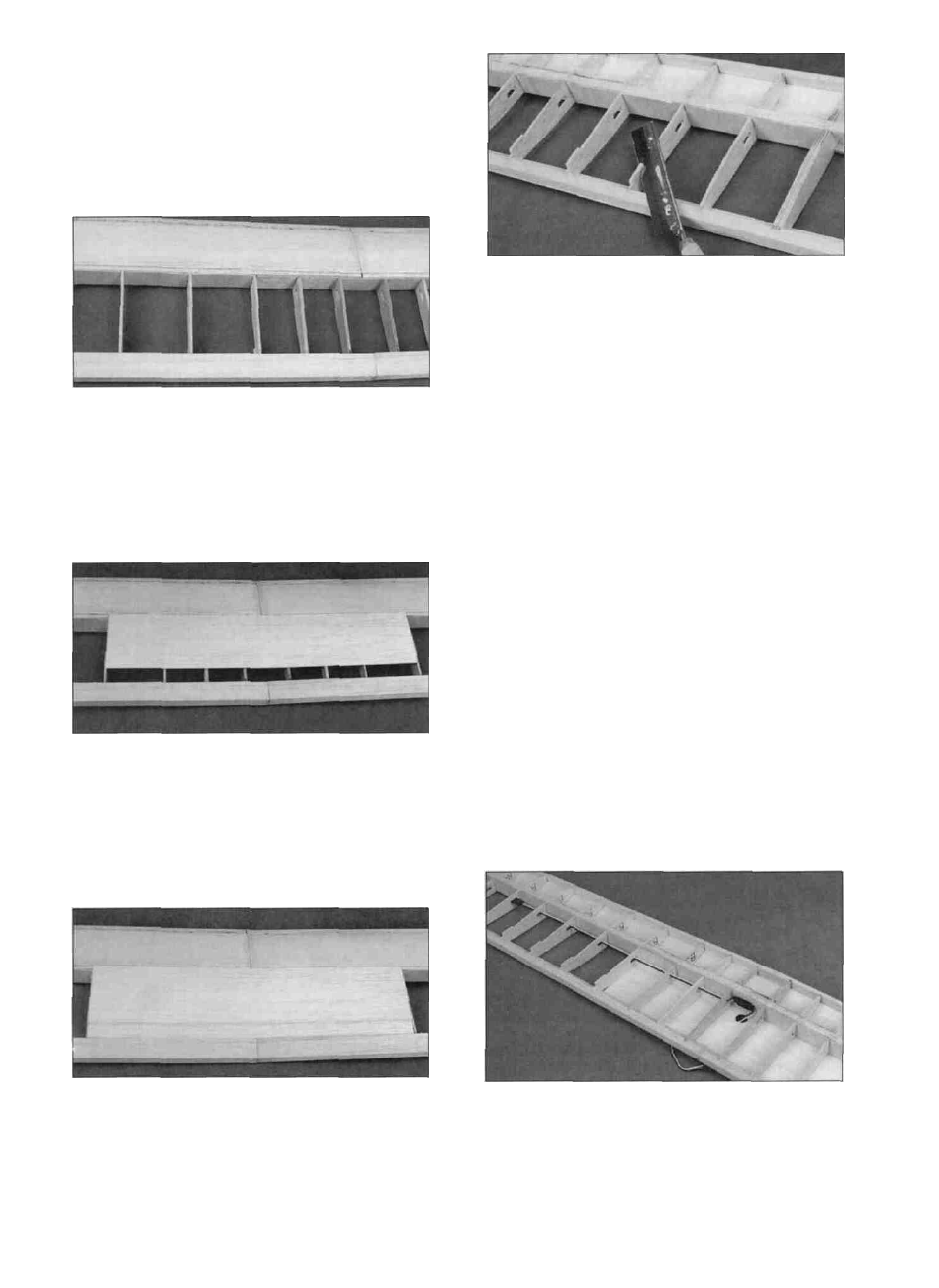

works OK) to hold the sheeting in place while the

glue cures. It is important to keep the wing flat

during this process as the LE sheeting will help

"lock" the wing together. We won't glue the

sheeting to the wing tip until later.

D 23. Flip the wing over, and carefully trim off the

jig tabs on the bottom of the wing. A razor saw

works well for this. Use a sanding block with fine

grit sandpaper to touch up where the tabs were,

and to blend the ribs into the TE. Be careful not to

change the shape of the ribs during this step.

D 20. Install the opposite wing panel top sheeting

following the same procedure. Cut and sand the

root end of the sheeting to fit nicely against the LE

sheeting already installed.

D 24. Add the two remaining 1/16" x 7/8" x 28"

balsa TE sheets just as you did earlier on the top

surface. Do one panel at a time, and be careful to

keep from warping the wing during these steps.

HINT: An aileron placed under the TE will keep it

straight while the glue is curing.

0 25. Install the two remaining 1/16" x 2-1/8" x 28"

bottom wing LE sheets, using the same procedure

outlined in steps 15-20. Be sure to keep the wing

absolutely flat during this step to avoid warps.

D 21. Position one of the 1/16" x 2-5/8" x 13-1/2"

wing center sheets as shown in the photo, and

glue it in place (against the LE sheeting). Allow the

sheeting to gently bend between the B1 ribs.

FINISH THE BOTTOM WING

IF YOU ARE USING ONLY ONE

AILERON SERVO SKIP TO STEP 2

D 22. Lay a 1/16" x 2-5/8" x 13-1/2" piece of balsa

center sheeting in place over the gap. Mark where

to cut it, trim it to fit, and glue it in place.

D 1. The aileron servo extension cables need to

be installed now. Approximately 24" of extensions

are required for each aileron. We used one

49-