Great Planes Super Skybolt 60 Kit - GPMA0170 User Manual

Page 17

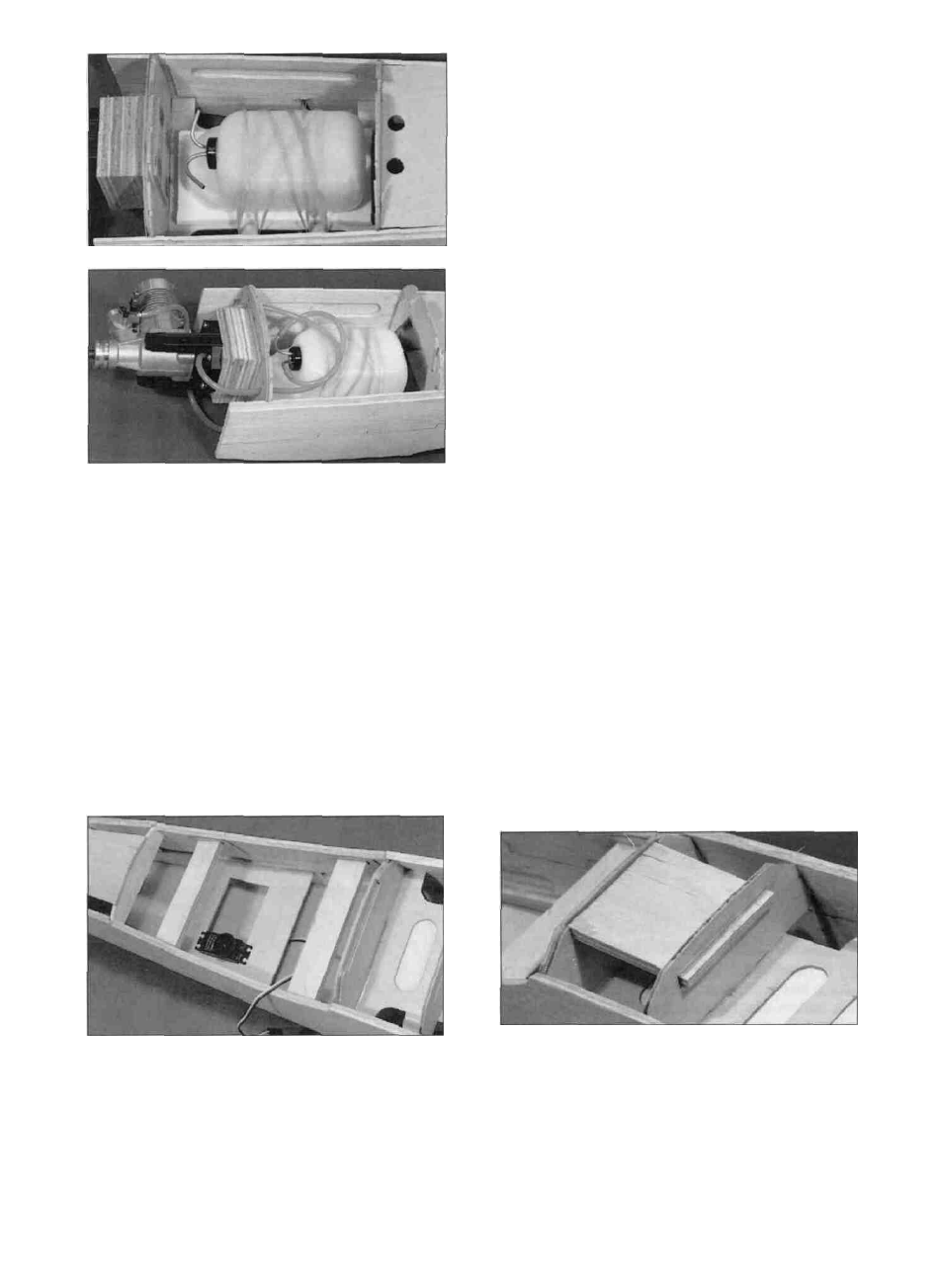

possible. Make sure you will still be able to install

and work on the servo linkages. These servo

positions are not critical, but will help you balance

the plane without using extra weight. The die-cut

1/8" ply servo tray (SKY6W10) is designed to fit in

the doubler lightening hole for most installations,

but will have to be cut down in width to fit towards

the rear of the plane. It can be glued just below

the lightening hole when it needs to be installed

farther forward as shown in the photo. Check your

servos to make sure they will fit into the tray and

are not held off the tray by the cockpit bottom.

Securely glue the tray in place.

D 3. Install the fuel tank using four #64 rubber

bands (not included) as shown in the photo.

Determine where the fuel and vent tubes should

pass through the firewall to match up with your

particular engine. Drill a 1/4" hole for each tube to

pass through the firewall. The larger holes will

allow you to seal around the tubes with silicone

bathtub sealer. Install the fuel tubing, but be sure

to leave a couple extra inches for good measure.

Mark on the front of the firewall which tube is fuel

and which is the vent.

D 5. Determine the location where the throttle

pushrod (not included) will pass through F1.

Normally, a solid wire pushrod will work fine for the

throttle pushrod. Drill a 3/16" hole (or whatever

size you need) in the firewall for the throttle

pushrod guide tube. Cut the outer guide tube to

length and roughen the outside of the tube with

medium grit sandpaper. Slide the tube into place

and glue it with thin and then thick CA. Refer to the

plans to get an idea of how to route the pushrod.

D 4. Determine where your servos should be

mounted. If you are using a lighter engine (.61 -

.75 2-cycle) the servos should go as far forward as

practical. If you are using a heavy engine (1.20

4-cycle) the servos should go as far back as

D 6. Locate the 1/4" x 2-3/4" x 3" ply landing

gear plate (SKY6F30) and test fit it in place

between LG-1 and LG-2. NOTE: The grain

should run from LG-1 to LG-2. Enlarge the slots

if necessary to get the plate to fit. When satisfied

with the fit, securely epoxy the plate in place.

17-