Examples, Example 1, Calibration procedure using weights – Flintec DAD 141.1 User Manual

Page 24: Example 1 – calibration procedure using weights

DAD 141.1 Technical Manual, Rev. 2.2 - February 2014

Page 24 of 54

8.

Examples

8.1. Example 1

– Calibration procedure using weights

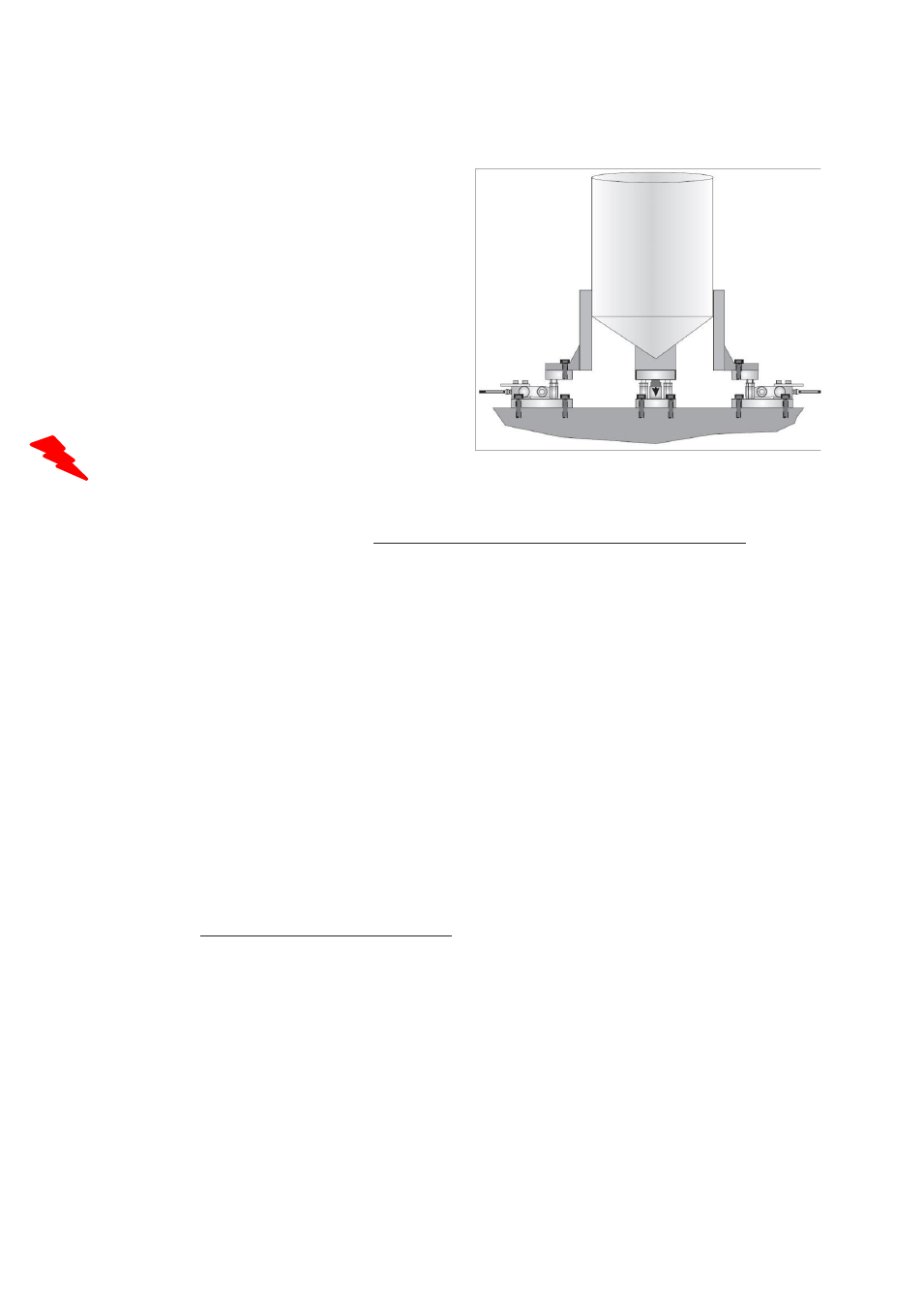

3 Leg tank or silo fitted with 3 load cells of 1000kg;

load cell signal @ 1000kg = 2 mV/V.

Dead load of tank / silo is 600kg.

Live range is 1 500kg, step size is 0.5kg.

It is assumed that the load cell system is connected

to the DAD 141.1 and the power is on. The maximum

and minimum display values, display increment size

and decimal point position should be defined prior to

carrying out the calibration (See chapter 7.5 menu 3).

For this example the display maximum is defined as

1600.0kg, the display minimum is -200.0kg, the

Display step size is 0.5kg.

Remember that all parameters of the menues 1.1 - 1.3, 2.1 - 2.3 and 3.1 - 3.3 can only be accessed or

changed after remove the jumper on the seal switch pins (28).

a A scale calibration by using weight(s) can only be performed in the scale sta

tus ‘no motion‘. This requires

in any case to check the settings of menu 4.

Recommendations for setup as follows:

-

Menu 4.1: set cut off frequency to 4.1.7 = 0.5Hz

-

Menu 4.2: choose IIR filter

-

Menu 4.4.1: set no motion range e.g. to 2, which means for this example 0.2kg

-

Menu 4.4.2: set no motion time to 1000, which means 1000ms or 1s

In case of outdoor application or indoor with a lot of mechanical noise from the floor/ground, may be you

have to change

the ‘no motion‘ settings.

b Go to Menu 3.2 (display step size) by using the UP/DOWN and ZERO keys. The display shows the

actual step size, e.g. 1. Now you can change step size by using the UP/DOWN keys and set to 5.

Press the ZERO key to store & leave menu point. This procedure defines the step size to 5, which leads

with the setup of decimal point to 0.5kg steps.

c Go to Menu 3.3 (decimal point position) by using the UP/DOWN and ZERO keys. The display shows the

actual decimal point, e.g. 0.0. Now you could change decimal point position by using the UP/DOWN

keys, but in this example we keep the setup. Press the ZERO key to store & leave menu point.

This procedure defines the decimal point position to 0.0, which leads to weight readings of e.g. 498.5kg.

d Go to Menu 1.2 by using the UP/DOWN and ZERO keys. The display shows the actual mV/V value,

e.g. 0.4107. Make sure that the tank/silo is empty or at the point where you want the display to read zero.

Press the ZERO key to set the display to read 0000.0kg. This procedure defines the actual zero calibration

point. Leave this menu point with ZERO key.

e Go to Menu 2.1 by using the UP/DOWN and ZERO keys. Set the display to read the span value of the

calibration weight(s) applied. For this example, if the calibration applied load is 750kg, set the display to

read 750.0. By using the UP/DOWN and TARE keys you have to setup each number of the 6 digit display

to 00750.0. Press now ZERO key for storage. This procedure defines the span calibration value.

Leave this menu point with ZERO key.

f Go to Menu 2.2. by using the UP/DOWN and ZERO keys. Apply the calibration weight(s) to the weighing

system. The display will show the actual input signal in mV/V, e.g. 0.9087. Press the ZERO key to set the

display to read 750.0kg. The gravimetric calibration is done.

Leave this menu point with ZERO key.