Flintec PC6D User Manual

Page 36

Page Manual PC6D CANopen

36

5.7 Setpoint Commands - Sn, Hn, An

The PC6D has 4 setpoints where the status is dependent on the weight value. Each of them

can be assigned as an independent setpoint value (Sn) with a corresponding

hysteresis/switch action (Hn) and base (An – switch on the gross or the net weight).

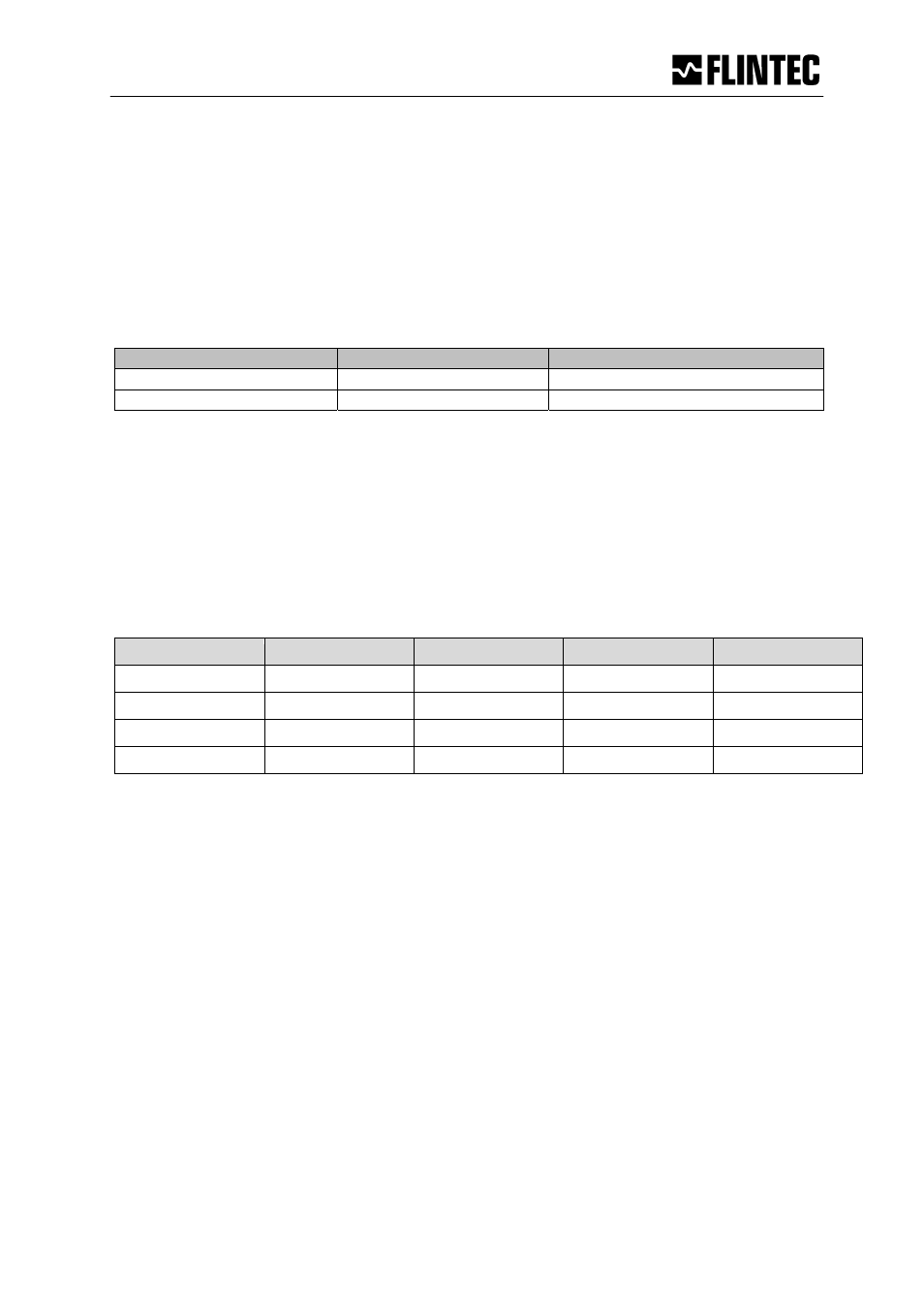

S1

Setpoint 1

[ 2600sub01 ]

Request / Setting

Master (PC / PLC) sends

Device responds

Result

S1 1+01500

Setpoint S1 = 1500 d

S1_03000 OK

Setting: Setpoint S1 = 3000 d

Similarly to read or set setpoint 2, use S2 instead of S1, etc.

(2600sub02)

H1

Hysteresis setpoint 1

[ 2700sub01 ]

Using the H1 command, the hysteresis on the setpoint value is set by the numeric value and

the polarity of this numeric value defines whether the setpoint switches on or off when the

setpoint value is reached.

Example

Setpoint

Hysteresis

Load

OFF

ON

S1 = 20.00 kg

H1 = -1.00 kg

increasing

≥ 21.01 kg

0 ... 21.00 kg

S1 = 20.00 kg

H1 = -1.00 kg

decreasing

≥ 20.00 kg

19.99 ... 0 kg

S1 = 20.00 kg

H1 = 1.00 kg

increasing

0... 19.99 kg

≥ 20.00 kg

S1 = 20.00 kg

H1 = 1.00 kg

decreasing

19.00. ..0 kg

≥ 19.01 kg

Example of negative hysteresis of 1.00 kg (H1 = -100) on a setpoint (S1) of 20.00 kg

(lines 1 & 2 of table above):

When the weight is increasing between 0 kg and 21.00 kg the setpoint is “ON”. Once the

weight increases above 21.00 kg then the logic output is “OFF”. The setpoint will come “ON”

again when the weight value drops below 20.00 kg.

Example of positive hysteresis of 100 kg (H1 = +1.00) on a setpoint of 20.00 kg

(lines 3 & 4 of table above):

When the weight is increasing between 0 kg and 19.99 kg the setpoint is “OFF”. Once the

weight increases above 19.99 kg then the setpoint is “ON”. The setpoint will switch “OFF”

again when the weight value drops below 19.00 kg.