Flintec PC6D User Manual

Page 27

Manual PC6D CANopen Page 27

5.2 Calibration Commands – CE, CM, DS, DP, CZ, CG, ZT, FD, CS

Note: TAC represents Traceable Access Code (calibration counter).

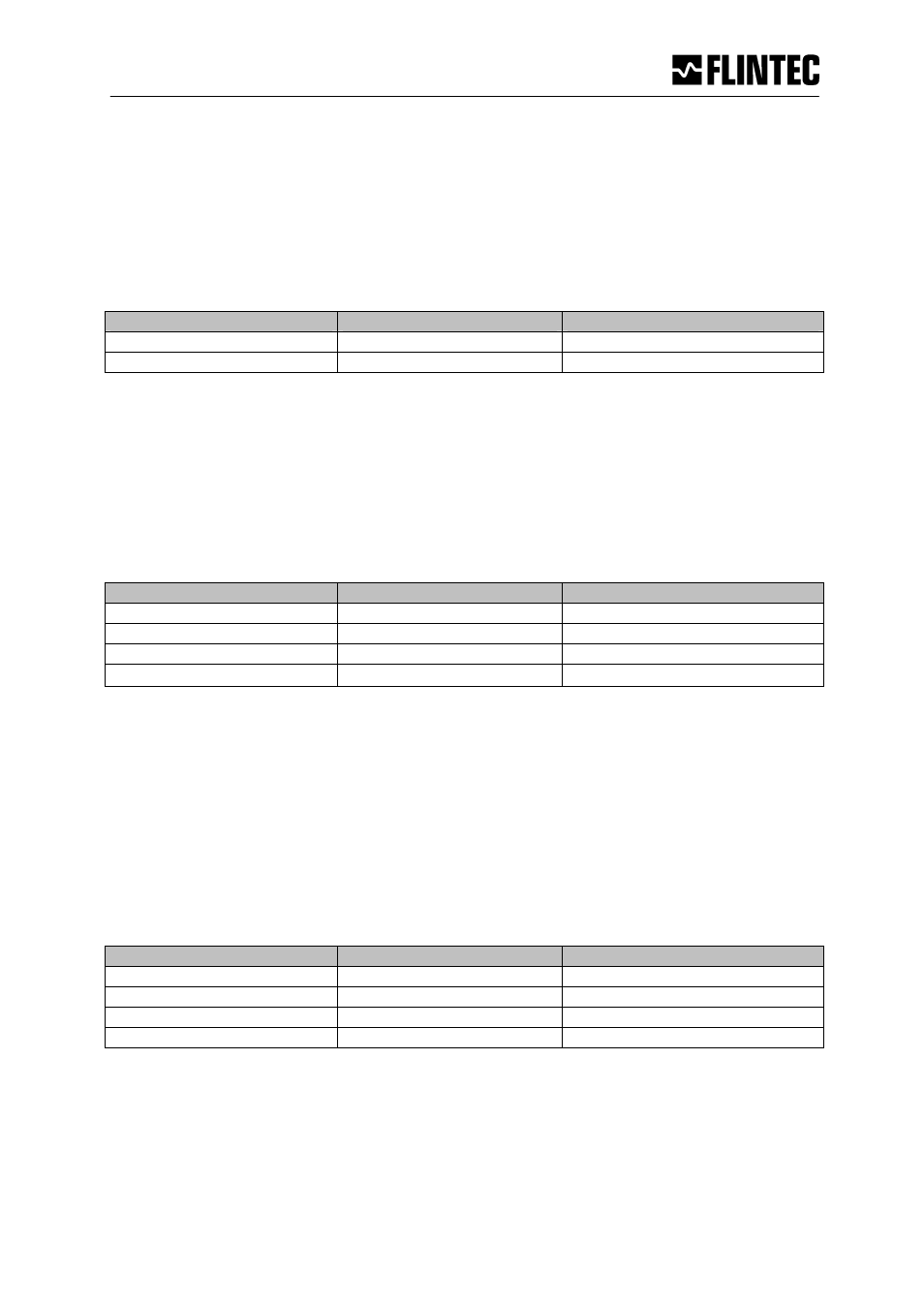

CE

TAC counter reading

[ 2300sub03 ]

With this command you get the TAC counter reading or you can enable a calibration

sequence.

Master (PC / PLC) sends

Device responds

Result

CE

E+00017 (example)

Request: TAC-counter CE 17

CE_17 OK

Calibration sequence active

This command must be issued PRIOR to any attempt to set the calibration parameters

CZ, CG etc. In legal for trade applications the TAC counter can be used to check if critical

parameters have been changed without re-verification. After each calibration the TAC

counter increases by 1.

CM

Set maximum output value

[ 2300sub07 ]

This command is used for setup the maximum output value. Permitted values are

between 1…200000.

Master (PC / PLC) sends

Device responds

Result

CM M+30000

Request : CM = 30000

CE

E+00017 (example)

Request: TAC-counter CE 17

CE_17 OK

Calibration sequence active

CM_50000 OK

Setting: CM = 50000

This value will determine the point at which the output will change to “oooooo”, signifying

over-range.

Note: The range, in which a scale can be set to zero (SZ) or automatic zero tracking (ZT) is

active, is +/- 2% of CM value.

Factory default: CM = 99999.

DS

Display step size

[ 2300sub0C ]

This command allows the output to step up or down by a unit other than 1. Permitted

values are 1, 2, 5, 10, 20, 50, 100 and 200.

Master (PC / PLC) sends

Device responds

Result

DS S+00002

Request : display step size 2

CE

E+00017 (example)

Request: TAC-counter CE 17

CE_17 OK

Calibration sequence active

DS_50 OK

Setting: DS = 50