Carl Goldberg GPMA1968 Tiger 60 ARF User Manual

Page 10

10

5.

Repeat these steps for the other half of the

wing, so that both servo extensions are exit-

ing the holes in the center of the wing.

WING INSTALLATION ON FUSELAGE

3.

Working with the fuselage upside down,

insert a 6-32 blind nut into each hole in the

wing mounting blocks, with the teeth pointing

upward into the blocks.

Temporarily insert a 6-32 x 1" screw into

each hole on the other side of the mounting

block and draw the blind nut teeth down into

the wood.

When the blind nuts are firmly seated in the

wing mount blocks, remove the screws.

FUSE SHOWN UPSIDE DOWN

SCREW

WING

BLIND NUT

4.

Gently prodding the covering, locate the hole

next to the center of the of the wing, close to

the trailing edge.

Carefully remove the covering OVER THE

HOLE in the wing on both the top and the

bottom.

Do the same to the other wing panel.

5.

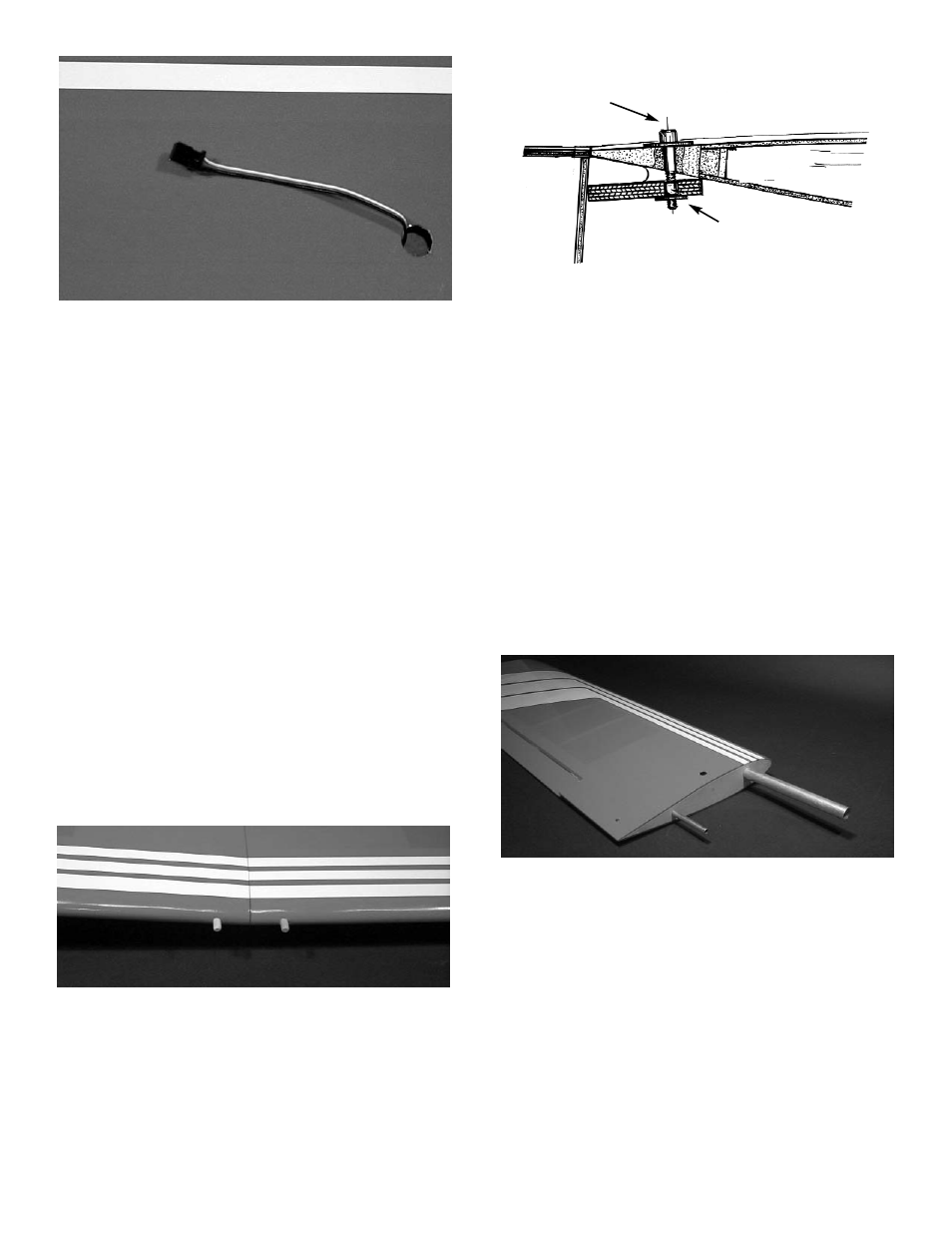

Insert the large aluminum tube into one wing

half and push the tube into the wing until it

stops. Then insert the small aluminum tube

into the small hole till it stops. Then slide the

wing halves together.

4.

Grasping the extension in the hole, SLOWLY

pull until the end of the 6" extension comes

out of the hole.

Tape the extension securely to the wing, so

that it will not slide back in while you are

working.

Screw the servo door into the wing.

NOTE: If the covering on your wing has loosened in

transit, refer to the covering section of the

"INTRODUCTION" before continuing.

1.

Collect the following items:

(1) Right wing

(1) Left wing

(2) 5/16 x 1-1/2" dowel

(1) Large aluminum tube

(1) Small aluminum Tube

(2) 6-32 x 1-1/2 Socket Head bolt

(2) 6-32 Blind nut

(2) #6 x 3/4” washer

2.

Using ZAP ZPOXY™, mount the 5/16 x 1-

3/4” dowels into the holes in the leading edge

of the wing. Make sure to leave about 1/2” of

dowel sticking out of the front of the wing. You

may wish to slightly taper the exposed dowel

ends for ease of insertion into the fuse holes.