Air shutter locking nut location, 4 propane combustion calibration, Initial start-up – AERCO KC Series Equipped with C-More version 3.04 User Manual

Page 36

INITIAL START-UP

4-6

50°F

5.4 %

<150 ppm

60°F

5.2 %

<150 ppm

70°F

5.0 %

<150 ppm

80°F

4.8 %

<150 ppm

90°F

4.6 %

<150 ppm

100°F

4.4 %

<150 ppm

REMINDER:

At 30% valve position adjust only the differential pressure regulator. At 100% valve position, adjust only

the inlet air shutter.

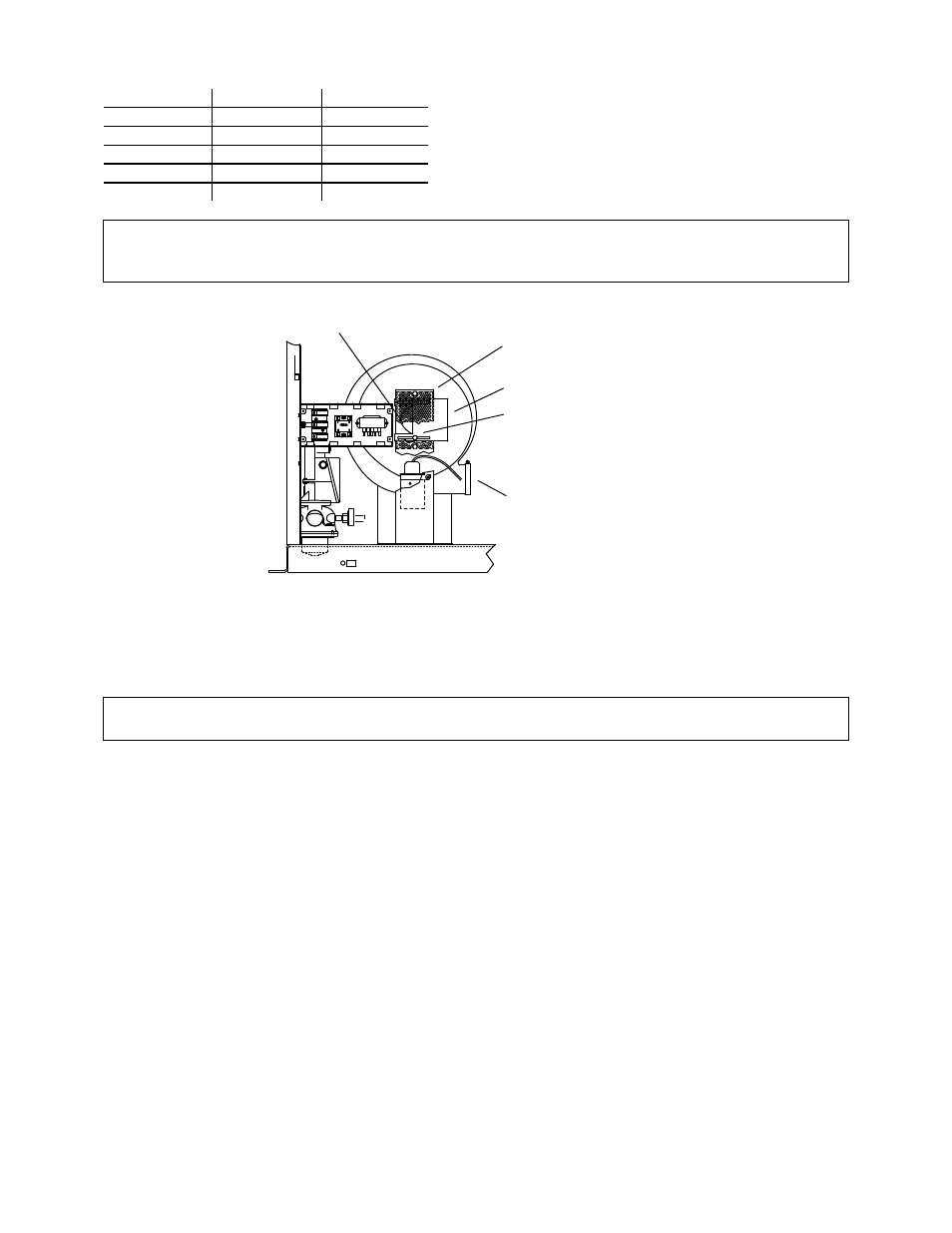

BLOWER

OUTLET

BLOWER

INLET

SCREEN

SHUTTER

SHUTTER

LOCKING NUTS

Figure 4.4

Air Shutter Locking Nut Location

25. Allow the analyzer to settle and then compare the new oxygen reading to Table 3.

26. Repeat the adjustment until the oxygen is within the specified range. Firmly tighten the inlet air shutter

locking nuts when finished.

NOTE:

Adjust the inlet air shutter only at 100% valve position. Do not adjust the differential pressure regulator.

27. Change the valve position to 30%. Allow time for the combustion analyzer to settle. Check the

measured oxygen reading to insure that it is still within the range as per Table 1.

28. Continue this procedure until all oxygen levels are within the ranges specified in Tables 1, 2 and 3.

29. Record all readings on the AERCO start-up sheet provided with each unit. Proceed to paragraph 4.5.

4.4 PROPANE COMBUSTION CALIBRATION

For propane units it will be necessary to install an additional 8” W.C. manometer. This manometer will be

used to measure the pressure drop across the air/propane mixing orifice. After performing the setup

procedures in paragraphs 4,2.2 through 4.2.4, install the 8” W.C. manometer as described in the following.

1. Referring to Fig. 4.5, remove the 1/8” NPT plug from the gas inlet pipe ahead of the burner and install

a 1/8” NPT barbed fitting.

2. Remove the 1/2” NPT plug from the tee located after the air pressure regulator and install a 1/2”

barbed fitting (see fig. 4.5).

3. Attach the 8” W.C. manometer to the barbed fittings installed in steps 1 and 2.

4.