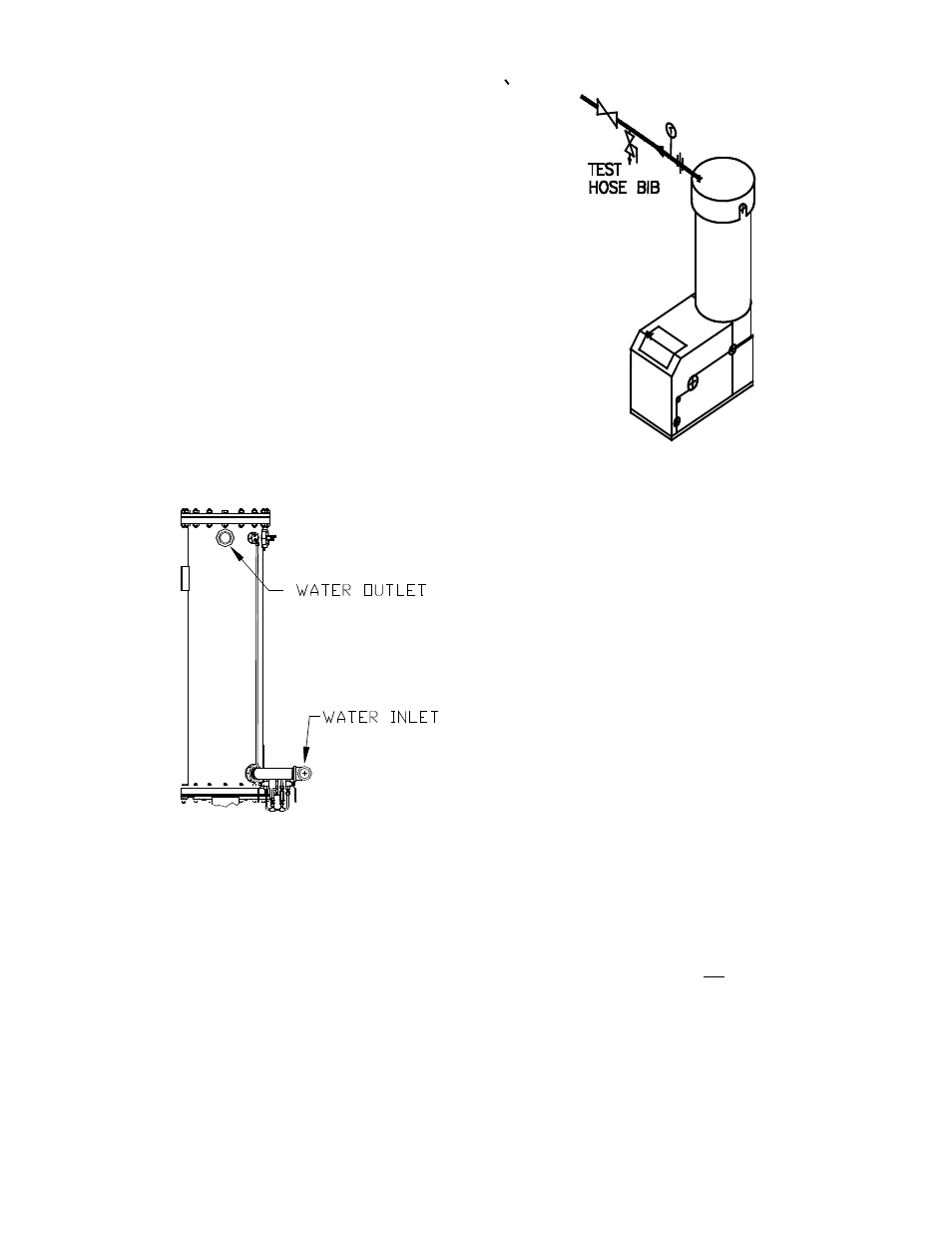

Figure 2.3, Inlet and outlet location, Installation – AERCO KC Series Equipped with C-More version 3.04 User Manual

Page 13

INSTALLATION

2-3

Shut-off valves and union conections must be

installed in the inlet and outlet lines for main-

tenance. The use of dielectric unions is recom-

mended. Install the piping and accessories as

per the following drawings, located in Appendix F

of this manual.

•

SD-A-424 for single units

•

SD-A-425 for multiple units

•

SD-A-432 for single units with a stratified

tank

•

SD-A-434 for multiple units with a stratified

storage tank

NOTE:

All piping must be arranged so that it does

not interfere with removal of any cover,

inhibit service or maintenance, or prevent

access between the unit and walls, or

another unit.

Figure 2.3

Inlet and Outlet Location

2.3.3 TEST HOSE BIB

A Test Hose Bib connection, upstream of the

shut off valve on the hot water outlet, is required

for startup and testing. It should be a minimum

of 3/4".

It cannot be omitted (See Fig. 2.4a)

Figure 2.4a

Hose Bib Location

NOTE:

The maximum working pressure for

installations within the Province of Alberta is

87 psig. Therefore, a pressure & temperature

relief valve with a setting of 75 psig/210°F is

supplied with Alberta shipments. See Drawing

AP-A-863 in Appendix E.

2.3.4 PRESSURE/TEMPERATURE

RELIEF & DRAIN

VALVE INSTALLATION

An ASME rated Pressure/Temperature Relief

Valve is supplied with each unit. With the

exception of Alberta installations (see above

Note), the valve setpoint is 150 psig/210°F.

Install the relief valve as shown in Figure 2.5. A

suitable pipe compound should be used on the

threaded connections. Any excess should be

wiped off to avoid getting any into the valve

body. The relief valve should be pipied to within

12 inches of the floor to prevent injury in the

event of a discharge. The relief piping must be

full size, 1-1/2”, without reduction. No valves,

restrictions, or other blockages are allowed in

the discharge line. In multiple unit installations

the discharge lines must not

be manifolded

together. Each must be individually run to a

suitable discharge location.

A 1” drain valve assembly is furnished with each

unit. The assembly should be installed as shown

in Figure 2.4b. The drain should be hard piped to

a suitable drain.