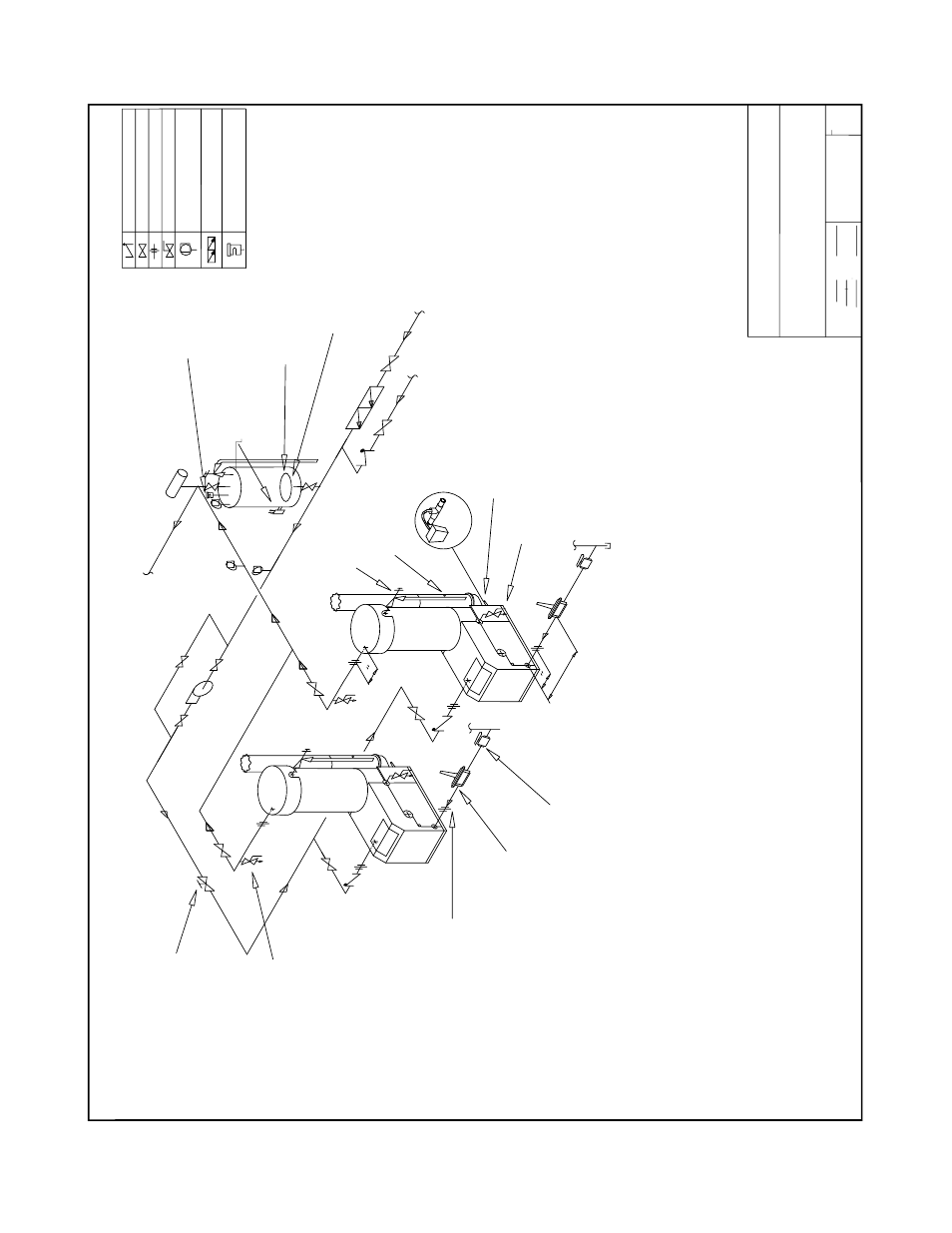

Aerco, Appendix f, Legend – AERCO KC Series Equipped with C-More version 3.04 User Manual

Page 103: Sd -a -434

APPENDIX F

F-4

COLD WATER IN

CONNECT

5/

8"

I.D

. HOSE TO CONDENSATE DRAIN

SHELL DRAIN VALVE

*

RELIEF VALVE

*

HOUSE RECIRCULATION

HOT WATER OUT

INLET BAFFLE

6

(NOTE

6)

6

TANK HEIGHT TO DIA

. RATIO

: 2

:1

MIN

.,

3:

1

PREFERRED

SIZE INLET FOR FLOW

<

2

FT

/SEC

OXYGEN ANALYZER

DIA

.=

2/

3

TANK DIA

.

EXPANSION TANK

MANDATORY GAS PRESSURE

INPUT

GAS IN

- SEE GF

-1030

FOR GAS PIPING INSTALLATION

MAINTAIN A REGULATED

8.

5"

W

.C

.

1-

1/

4"

MANUAL SHUTOFF

*

DIRT TRAP

T

T

T

THROTTLING VALVE

- SET AT

DRAIN

FLOW CAPACITY OF HEATER AT REQUIRED TEMP

. RISE

2'

(NOTE

6)

PUMP

SWITCH

TEMPERATURE

(NOTE

8)

CHECK VALVE

THERMOMETER

DRAIN VALVE

STOP VALVE

T

UNION

LEGEND

GAS FIRED WATER HEATER

KC

1000 1

MIL

. BTU

MULT

. UNIT

&

STRAT

. TANK INSTALLATION

NORTHVALE

, NJ

07647

INTERNATIONAL

, INC

.

APPD

.

DWN

.BY

SCALE

DATE

MPC

122298

DATE

SCD

NTS

111198

AERCO

SD

-A

-434

G

REV

.

PRESSURE AT MAXIMUM BTU

/H

REGULATOR

(SUPPLIED BY OTHERS

)

TAP FOR

(SEE NOTE

7)

HOSE CONNECTION

(WHEN EMPLOYED

)

(NOTE

10

)

(NOTE

12

)

BREAKER

VACUUM

VACUUM BREAKER

BACKFLOW PREVENTER

NOTES

:

1.

FOR ACTUAL SIZES AND LOCATIONS OF PIPING AND OTHER CONNECTIONS TO THE HEATER

, SEE DIMENSIONAL DRAWING

2.

SHELL DRAIN VALVE AND CONDENSATE HOSE SHOULD BE ARRANGED TO PERMIT THE FLUIDS TO DRAIN FREELY

, BY

GRAVITY

, TO A FLOOR DRAIN

. RELIEF VALVE SHOULD BE PIPED VERTICALLY TO A HEIGHT

18

" ABOVE THE FLOOR

.

3.

ALL

(*)

ITEMS ARE INCLUDED SEPARATELY IN SHIPMENT

.

4.

THIS IS A TYPICAL INSTALLATION DRAWING

. LOCAL CODES AND AUTHORITIES SHOULD BE CONSULTED

.

5.

HOSE CONNECTION AT HEATER OUTLET IS FOR INITIAL HEATER CALIBRATION DURING START

-UP

.

6.

LOCATE WATER INLET AND OUTLET FITTINGS

(i.

e.

UNIONS

, ELBOWS

, ETC

.)

A MINIMUM OF

6"

FROM WATER HEATER

FITTINGS

, TO PREVENT INTERFERENCE WITH REMOVAL OF HEATER PANELS

. WHEN A FLEX CONNECTOR IS FACTORY

SUPPLIED BY AERCO

, IT MUST BE INSTALLED AT THE HOT WATER OUTLET CONNECTION OF THE WATER HEATER

. ALL

PIPING

&

ELECTRIC CONNECTIONS SHOULD BE

6"

AWAY FROM SIDE PANELS

. LOCATE GAS PRESSURE REGULATOR A

MINIMUM OF

2'

FROM HEATER

.

7.

PUMP SHOULD BE CAPABLE OF HEATER

'S RATED FLOW AT DESIGN TEMPERATURE RISE

.

8.

MOUNT TEMPERATURE SWITCH

1/

3

UP FROM THE BOTTOM OF THE TANK

, SWITCH WILL TURN PUMP ON AND OFF

.

9.

HEATERS SHOULD BE PIPED REVERSE RETURN AS SHOWN OR BALANCING DEVICES ON THE HEATERS SHOULD BE

EMPLOYED

.

10

. IF PERMITTED BY LOCAL CODES

, A CHECK VALVE MAY BE USED IN PLACE OF A BACKFLOW PREVENTER

.

11

. CONSULT LOCAL CODES FOR PROPER TYPE OF CONNECTIONS TO STORAGE TANK

.

12

. WHEN REQUIRED BY LOCAL CODES

, A VACUUM BREAKER MUST BE INSTALLED WITH THE STORAGE TANK

.