Figure 2.4b, Figure 2.5, Condensate drain assembly location – AERCO KC Series Equipped with C-More version 3.04 User Manual

Page 14: 4 gas supply piping, Installation

INSTALLATION

2-4

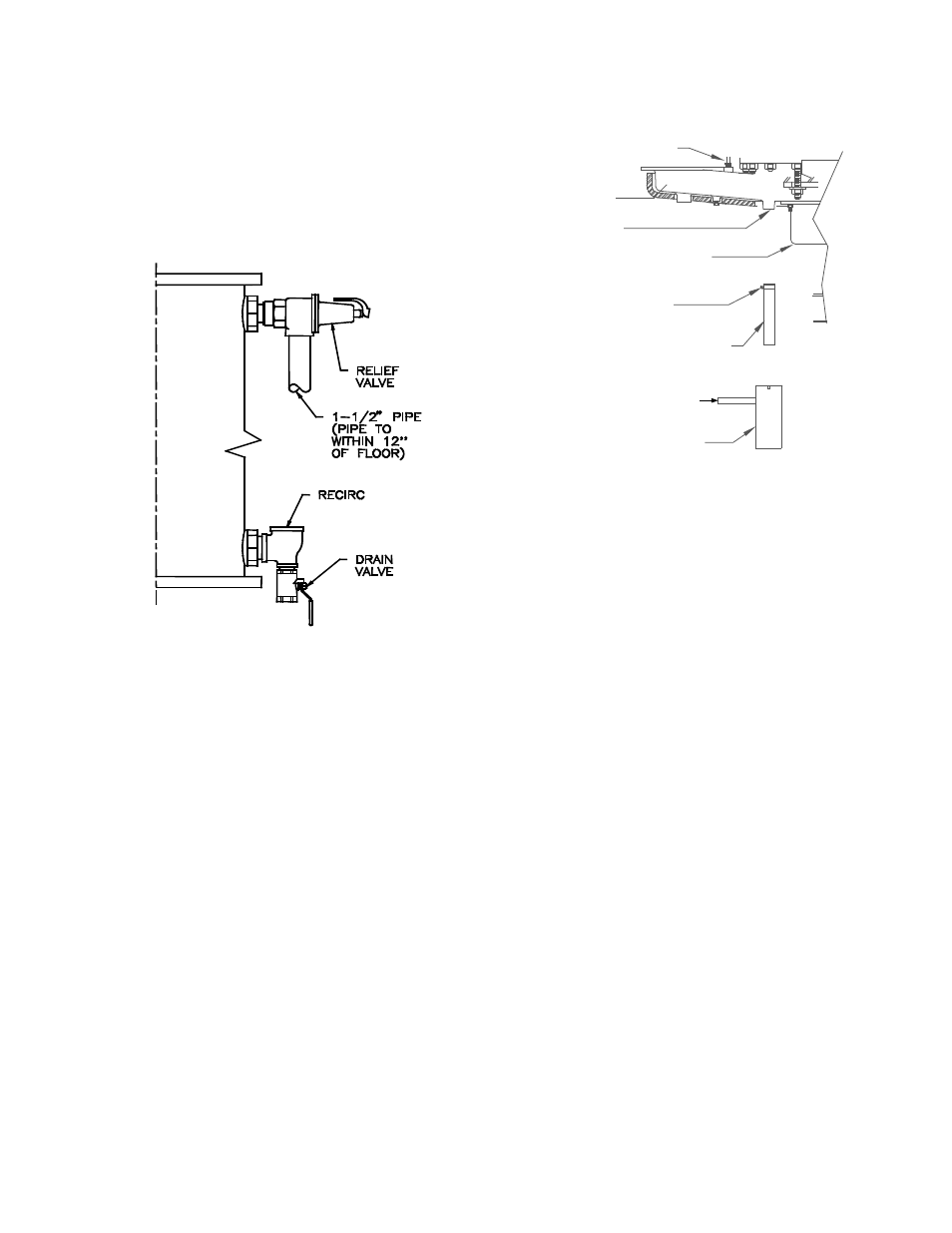

2.3.5 SYSTEM RECIRCULATION

The system recirculating line ties into the unit at

the recirculating tee fitting provided in the drain

valve assembly (see Fig. 2.4b). Shut off valves

and union connections are recommended for

maintenance. Recirculation flow rates must be

kept to 8 gpm or less. In a multiple unit

installation, each unit must be tied into the

system recirculation system.

Figure 2.4b

Pressure/Temperature Relief and Drain

Valve Installation Location

2.3.6 CONDENSATE PIPING

The KC Heater is designed to condense.

Therefore, the installation site must include

suitable provisions for condensate drainage or

collection. A stainless steel condensate cup is

separately packed within unit’s shipping

container. To install the condensate cup,

proceed as follows:

1. Remove the left side panel and only the left

half of the rear cover to provide access to the

exhaust manifold and burner (Figure 2.5).

2. Insert the 1-3/4 inch manifold drain hose into

the condensate cup. Allow the cup to rest on

the floor directly beneath the manifold drain

hole (Figure 2.5).

3. Attach a length of 3/4 inch I.D.polypropylene

tubing to the condensate cup drain tube and

route it to a floor drain. . If a floor drain is not

available, a condensate pump can be used to

remove the condensate to drain. The

condensate drain line must be removable for

routine maintenance.

4. Replace the rear cover and side panel on the

unit.

TEMPERATURE SENSOR

EXHAUST

MANIFOLD

CONDENSATE

DRAIN

BURNER

HOSE CLAMP

1-3/4" O.D. x 8-1 /2 “ LG.

SILICONE HOSE

5/8" O.D. TUBE CONN.

CONDENSATE CUP

PLACED ON FLOOR

Figure 2.5

Condensate Drain Assembly Location

2.4 GAS SUPPLY PIPING

AERCO Gas Fired Equipment Gas Components

and Supply Design Guide (GF-1030) should be

consulted before any gas piping is designed or

started.

WARNING !

DO NOT USE MATCHES, CANDLES,

FLAMES OR OTHER SOURCES OF

IGNITION TO CHECK FOR GAS LEAKS

.

CAUTION !

Many soaps used for gas pipe leak testing

are corrosive to metals. The piping must be

rinsed thoroughly with clean water after

leak checks have been completed

.

NOTE:

All gas piping must be arranged so that it

does not interfere with removal of any

cover, inhibit service or maintenance, or

prevent access between the unit and walls,

or another unit

.

The location of the 1-1/4" inlet gas connection

on the right side of the unit is shown in Figure

2.6.