Figure 7.6, Air/fuel valve inlet hose clamp, Figure 7.7 – AERCO KC1000 Boiler equipped with Mod-Box Controller User Manual

Page 41: Figure 7.8, Manifold nut and bolt locations, Maintenance

MAINTENANCE

36

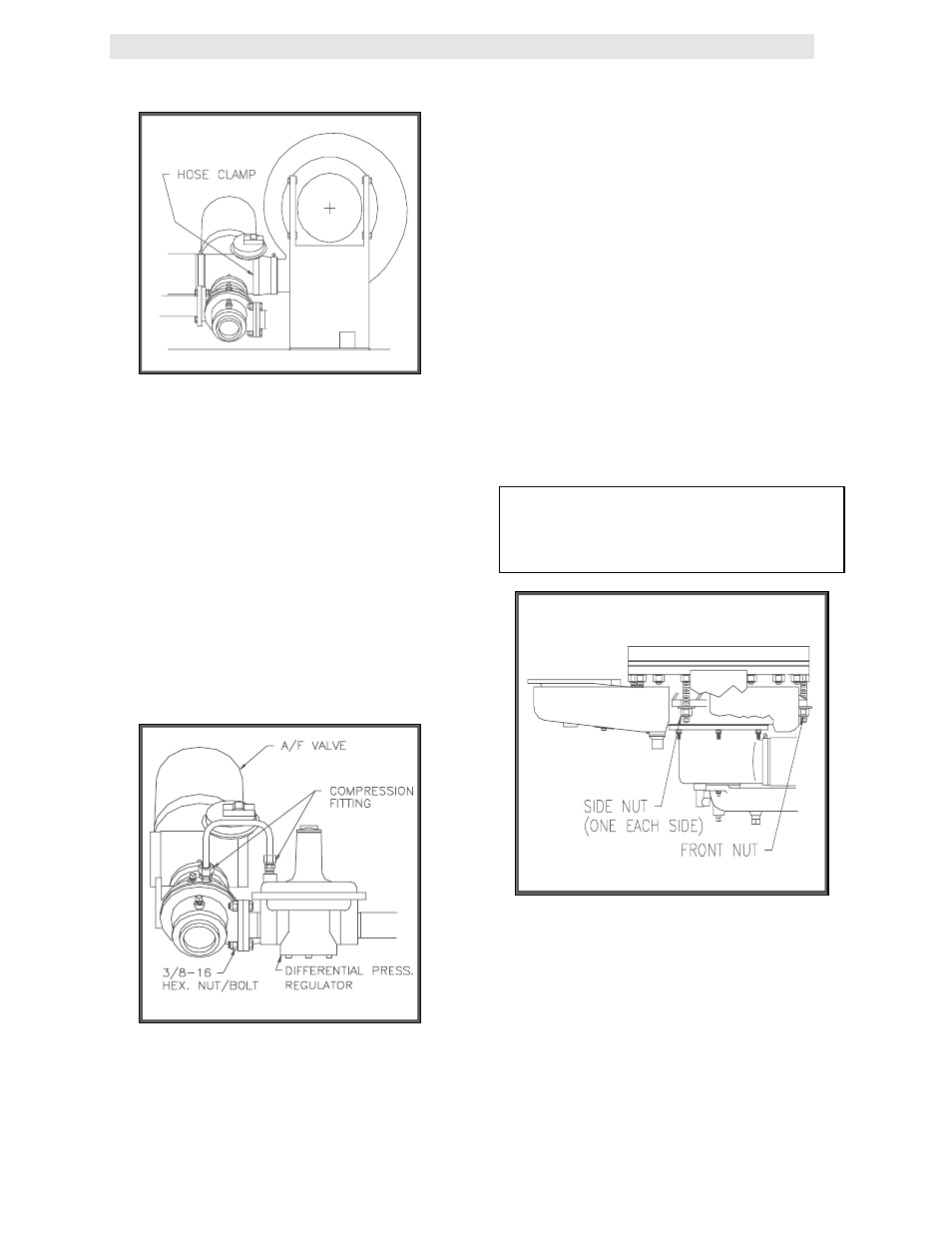

Figure 7.6

Air/Fuel Valve Inlet Hose Clamp

16. Using an 11/16” wrench, loosen the

compression fittings on the feedback tube

between the air/fuel valve and the differential

pressure regulator. Remove the feedback

tube (See Fig. 7.7).

17. Using two 9/16” wrenches remove the two

3/8-16 hex nuts and bolts holding the air/fuel

valve to the differential pressure regulator

(See Fig. 7.7).

18. Remove the air/fuel valve taking care not to

damage the flange “O”- ring.

19. Remove the flue venting from the exhaust

manifold.

Figure 7.7

Feedback Tube and Air/Fuel Valve to Differential

Regulator Bolts

20. To prevent damage to and for easier

handling of the exhaust manifold it will be

necessary to remove the exhaust manifold

insulation. Using a 7/16” wrench or socket,

remove the 3 bolts and fender washers

securing the insulation to the exhaust

manifold.

21. Loosen the three 1-1/16” nuts that hold the

manifold. Remove the two side nuts. DO

NOT REMOVE THE FRONT NUT (See Fig.

7.8).

22. Carefully pull the manifold down and back,

removing it through the back of the unit.

23. Inspect the manifold and exhaust tubes for

debris. Clean out any debris as necessary.

24. Inspect the combustion chamber and the

combustion chamber liner. Replace the liner

if any signs of cracking or warpage are

evident.

NOTE:

The combustion chamber liner should be

installed prior to reinstalling the exhaust

manifold

Figure 7.8

Manifold Nut and Bolt Locations

25. Replace the gasket between the manifold

and the combustion chamber (P/N GP-

122537). The use of Permatex or a similar

gasket adhesive is recommended. Replace

the gasket between the manifold and

tubesheet (P/N GP-18900). Do not use any

gasket adhesive; this gasket has an

adhesive backing

.