4 4 to 20ma direct drive mode, 1 4 to 20ma direct drive field wiring, 2 4 to 20 ma direct drive startup – AERCO KC1000 Boiler equipped with Mod-Box Controller User Manual

Page 31: 5 boiler management system (bms), Mode of operation

MODE OF OPERATION

26

5. Follow the above directions to change back

to remote mode.

NOTE:

The unit automatically defaults to remote

mode upon AC power being applied. This is

due to the presence of the external

interface board.

5.4 4 to 20MA DIRECT DRIVE MODE

In this mode of operation the 4 to 20ma signal

sent to the unit changes the unit’s percentage of

firing rate. The signal is typically sent from an

energy management system that, through PID

controls, determines the rate of change

necessary in the supply header. The 4 to 20ma

signal sent from the energy management system

equals a firing rate between 0 to 100%. In this

mode 4ma equals 0% firing rate and 20ma

equals 100% firing rate. The unit is a slave to the

energy management system and does not have

a role in temperature control. This mode of

operation can be used to drive single as well as

multiple units.

In this mode, the external interface board is

utilized. The interface board, located in the

external field wiring box, is factory configured

and converts the 4 to 20ma signal to an RS-485

signal. The RS-485 signal is in turn sent to the

temperature controller. For the temperature

controller to recognize a signal, from an external

source, the following functions must be correctly

set.

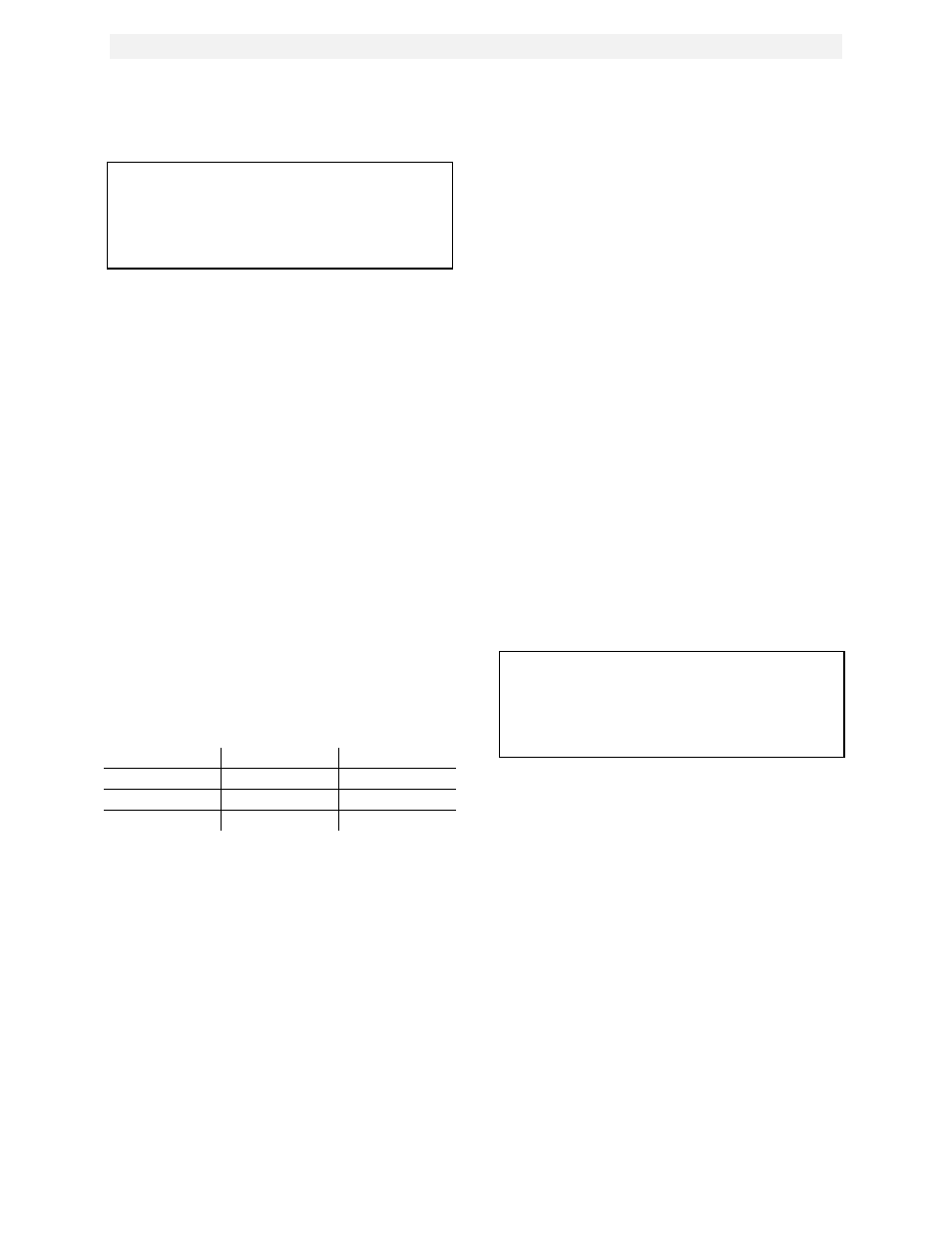

MENU FUNCTION

SETTING

Secondary Lore

re

Secondary FUNC

Cont

Primary

Auto

OFF

5.4.1 4 to 20MA DIRECT DRIVE FIELD

WIRING

The only wiring necessary is the 4 to 20 ma

signal from the source, to terminals 13 and 14 in

the external field wiring box. The signal must be

floating, (ungrounded), and the wire used must

be a two wire shielded cable of 22 gauge

minimum. Polarity must be observed and the

shield must be connected to terminal 1 in the

external wiring relay box. The source end of the

end must be left floating and not connected.

When driving multiple units, each unit’s wiring

must conform to the above.

5.4.2 4 to 20 MA DIRECT DRIVE

STARTUP

Since this mode of operation is factory preset

and the percentage of firing rate is being

externally controlled there are no startup

instructions necessary. However the unit must

be taken out of remote mode, and set to local

mode, to manually run the unit. Once finished

with manual mode, it is necessary to set the unit

back to remote mode for it to accept signals

from an external source. The temperature

controller must also be left in manual and not

automatic mode.

To set the unit to local mode do the following:

1. Access the temperature controller’s

secondary menu.

2. Scroll through the menu until "lore" is

displayed.

3. Use

the

⇑ ⇓ keys to set the temperature

controller to local. The yellow REM light, on

the temperature controller, should extinguish

4. Press ENTER to accept the change.

5. Follow the above directions to change back

to remote mode.

NOTE:

The unit automatically defaults to remote

mode upon AC power being applied. This

is due to the presence of the external

interface board.

5.5 BOILER MANAGEMENT SYSTEM

(BMS)

The BMS mode of operation is used when it is

desired to operate multiple units in the most

efficient manner possible. A total of eight units

can be managed by a single AERCO BMS 168

system. In BMS mode, the Boiler Management

System modulates the units firing rate. All

temperature functions are monitored and

controlled by the BMS panel. For BMS

programming and operation see the BMS

Operations Guide.

In BMS mode, the external interface board is

utilized. The interface board, located in the field

wiring box, is factory configured, and converts

the pulse width modulation signal, sent from the

BMS, to an RS-485 signal. The RS-485 signal is

then sent to the temperature controller. For the

temperature controller to recognize a signal,