Figure 3.1, Front panel controls location, Control panel operating procedures – AERCO KC1000 Boiler equipped with Mod-Box Controller User Manual

Page 15

CONTROL PANEL OPERATING PROCEDURES

10

SECTION 3- CONTROL PANEL OPERATING PROCEDURES

The following is a guide to the operation of the

control panel. Initial start-up of this unit must be

performed by factory trained start-up personnel.

Operation prior to initial start-up by factory

trained personnel will void the warranty.

CAUTION:

All initial installation procedures must be

satisfied before attempting to start the unit.

WARNING:

DO NOT ATTEMPT TO DRY FIRE THE KC

1000. STARTING THE UNIT WITHOUT A

FULL WATER LEVEL CAN SERIOUSLY

DAMAGE THE UNIT AND MAY RESULT IN

PERSONNEL INJURY OR PROPERTY

DAMAGE. THIS SITUATION WILL VOID

ANY WARRANTY.

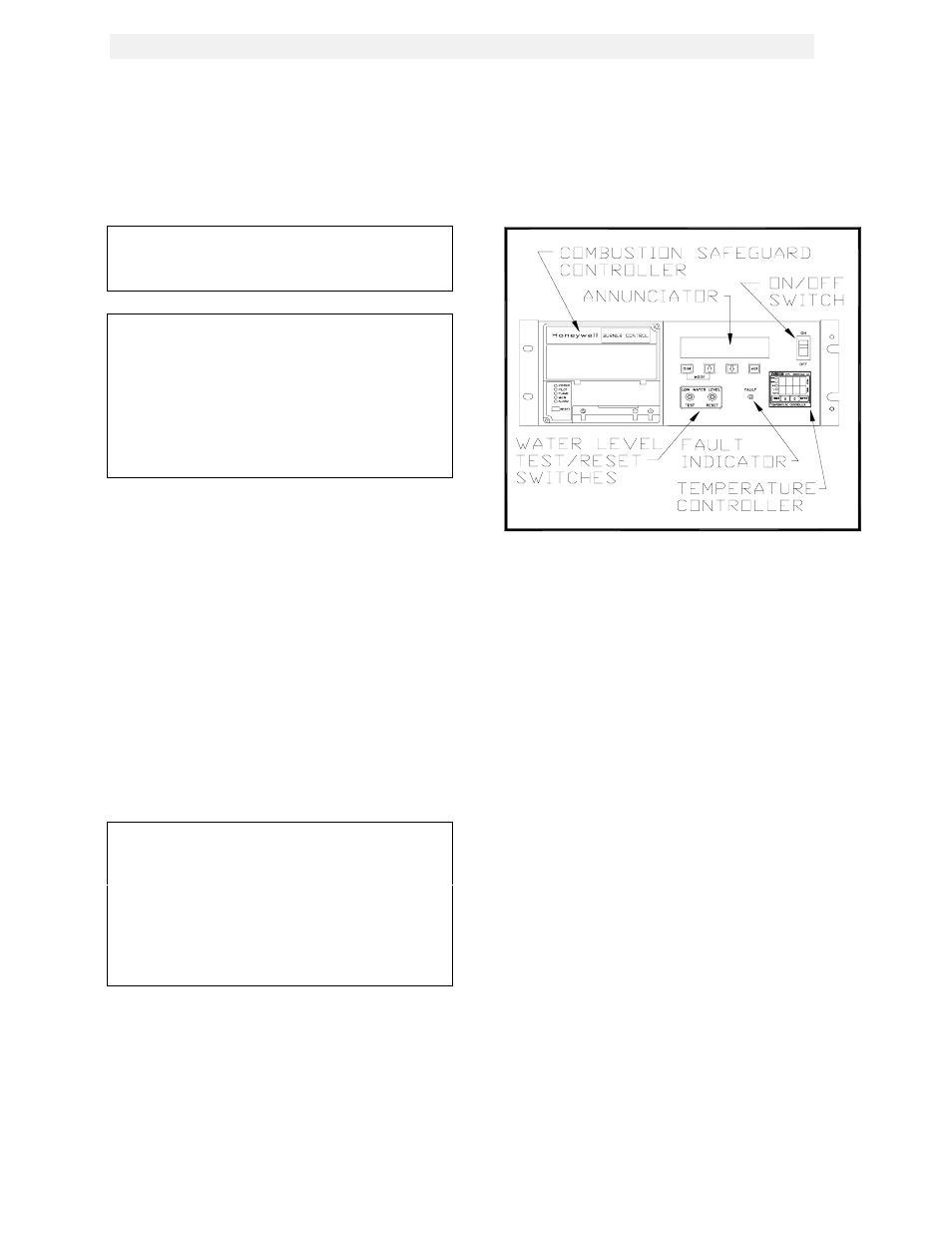

3.1 THE CONTROL PANEL

The KC 1000 Control Panel has been designed

to provide the operator with all the necessary

information required for operating and

troubleshooting this unit. There are six separate

accessible controls or displays, available to the

operator, (see Fig. 3.1). These are:

1. The Temperature Controller

2. The Annunciator & Function Switches

3. The Combustion Safeguard Controller

4. Water Level Test and Reset Switches

5. On/Off

Switch

6. Fault Indicator Light

The following sections will describe the above

components in more detail.

WARNING

CONTROL BOX INTERNALS MUST NOT

BE SERVICED OR ACCESSED BY

OTHER THAN FACTORY CERTIFIED

SERVICE TECHNICIANS. ALL CONTROL

BOX INTERNALS HAVE THE CAPABILITY

OF HOLDING AN ELECTRICAL VOLTAGE

OF 120 VOLTS AC.

3.2 THE TEMPERATURE CONTROLLER

The temperature controller is a PID

programmable controller that utilizes feed

forward and feedback information to accurately

maintain a desired set point. It is the primary

source for programming and viewing operating

parameter settings. It plays a part in the start

sequence and includes other features such as:

•

2- eight segment LED displays

•

5 indicator status lights

•

3 menu levels

•

RS-485 communications capability

Figure 3.1

Front Panel Controls Location

3.2.1 LED DISPLAYS

The upper and lower displays each consists of

four, 8 segment LED’s (see Fig. 3.2). When

choosing an operating parameter to be changed

or looked at, the lower LED display indicates the

parameter being looked at in the form of a code.

The upper display indicates the parameter’s

value. For a complete listing of the operating

parameters, see Appendix A of this manual.

3.2.2 INDICATOR STATUS LIGHTS

The first LED indicator light, “MAN” indicates

whether the controller is in auto or manual

mode, (see Fig 3.2). When lit the controller is in

manual mode and the operator is responsible for

operation of the unit. When the LED is not lit the

controller is in auto mode. In auto mode the

controller is operating the unit from signals

generated by sensors located on the unit or in

the system, or by signals from an energy

management system.

The second LED, “REM”, designates whether

the controller is being controlled locally or

remotely, (see Fig. 3.2). When lit the controller is

in remote mode and can accept commands from

an external source via the RS-485 interface.

When this LED is not lit the controller is in local

mode and will respond to whatever the current

internal settings are. All external commands are

ignored.