Pressure /temperature gauge installation, Pressure/temperature gauge installation, Condensate drain system location – AERCO KC1000 Boiler equipped with Mod-Box Controller User Manual

Page 10: Installation

INSTALLATION

5

Figure 2.5b

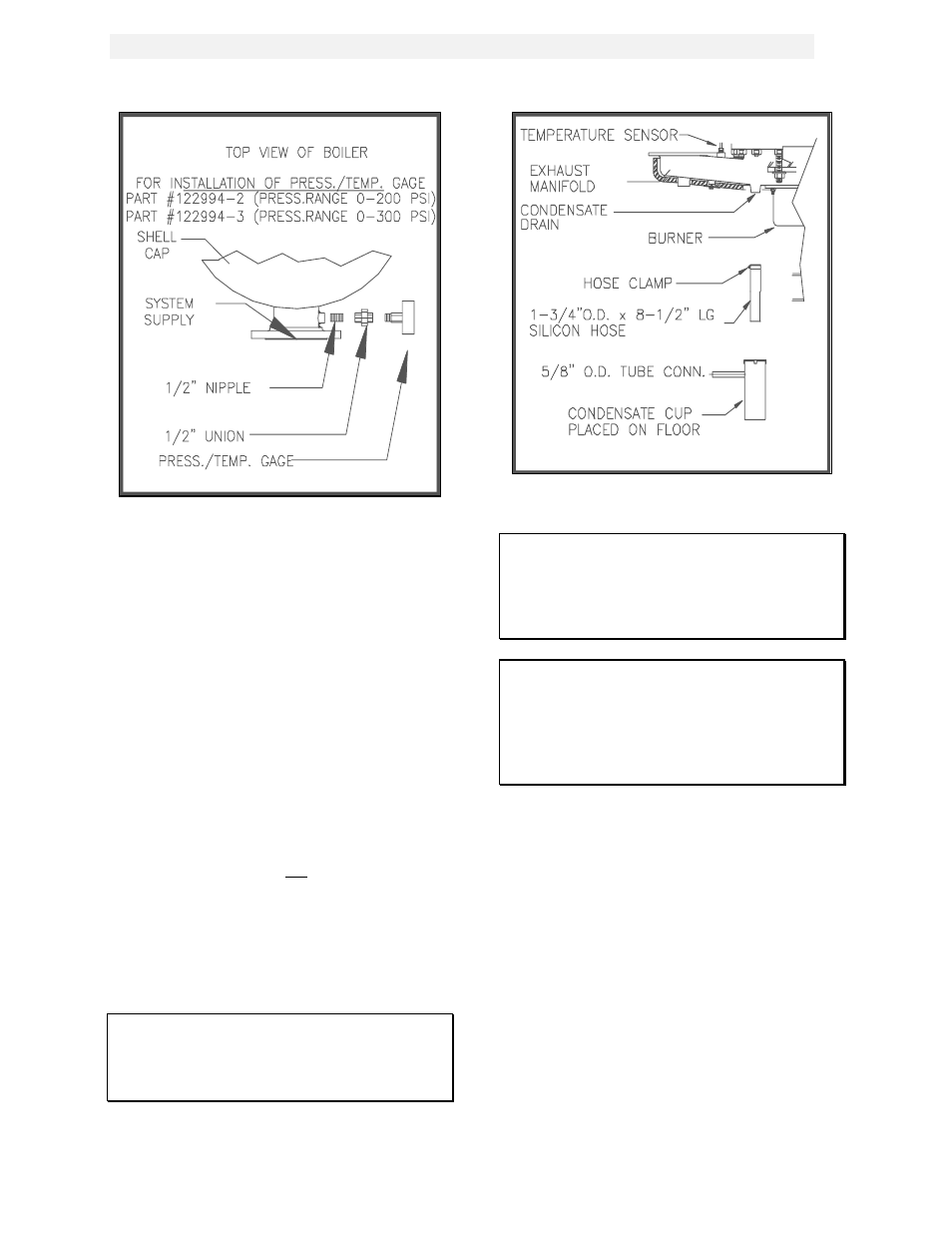

Pressure/Temperature Gauge Installation

2.3.5 CONDENSATE PIPING

The KC Boiler is designed to condense and the

installation must have provisions for drainage to

a suitable waste. A 1-3/4” inch O.D. silicone

hose, supplied with the unit, directs condensate

from the exhaust manifold to a stainless steel

condensate cup. The condensate cup is shipped

loose and should be installed inside the unit

directly under the manifold’s condensate

drainage hole (see FIG. 2.6). A 5/8-inch O.D.

flexible polypropylene tubing (or suitable

equivalent) can be used to carry the condensate

by gravity to a nearby floor drain. If a floor drain

is not available, a condensate pump can be

used to remove the condensate to drain. The

maximum condensate flow rate is 5 GPH. The

condensate cup and line must be removable for

routine maintenance. Do not hard pipe.

2.4. GAS SUPPLY PIPING

The AERCO

Gas Fired Equipment Gas

Components and Supply Design Guide (GF-

1030) must be consulted before any gas piping

is designed or started.

WARNING!

DO NOT USE MATCHES, CANDLES,

FLAMES OR OTHER SOURCES OF

IGNITION TO CHECK FOR GAS LEAKS

.

Figure 2.6

Condensate Drain System Location

CAUTION!

Soaps used for gas pipe leak testing can be

corrosive to metals. Piping must be rinsed

thoroughly with clean water after leak

checks have been completed.

NOTE:

All gas piping must be arranged so that it

does not interfere with removal of any

cover, inhibit service or maintenance, or

prevent access between the Unit and walls,

or another unit.

The location of the 1-1/4" inlet gas connection is

on the right side of the unit as shown in Figure

2.7.

All pipe should be de-burred and internally

cleared of any scale or iron chips before

installation. No flexible connectors or non-

approved gas fittings should be installed. Piping

should be supported from floor or walls only and

must not be secured to the unit.

A suitable piping compound, approved for use

with gas, should be used sparingly. Any excess

must be wiped off to prevent clogging of

components.