Figure 3.9, Combustion safeguard status indicator led location, Figure 3.10 – AERCO KC1000 Boiler equipped with Mod-Box Controller User Manual

Page 20: Water level test and reset switch locations, Control panel operating procedures

CONTROL PANEL OPERATING PROCEDURES

15

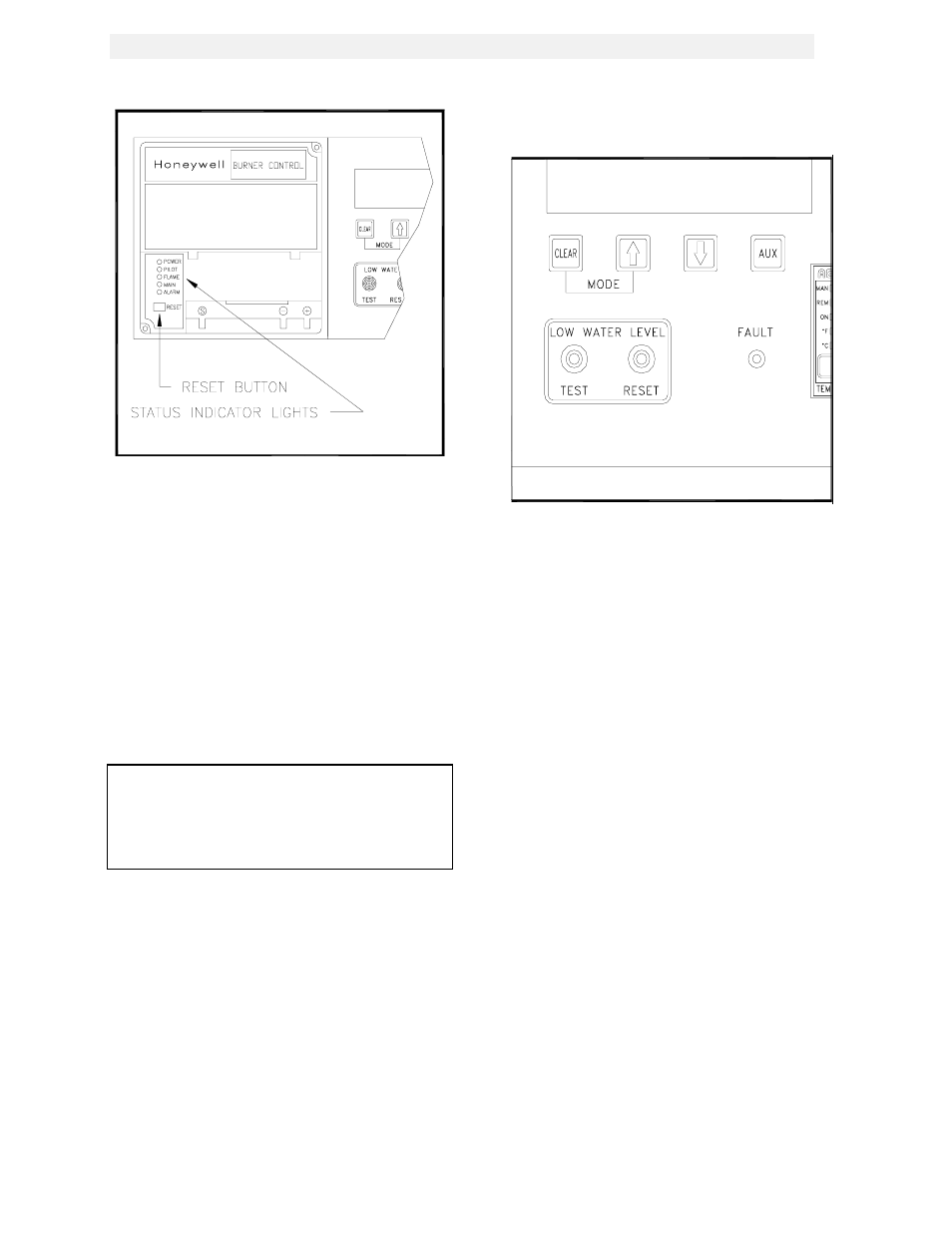

Figure 3.9

Combustion Safeguard Status Indicator LED

Location

3.7 WATER LEVEL TEST and RESET

SWITCHES

The water level switches are located on the left

side of the control box, see Fig. 3.10). When

depressed the TEST switch simulates a low

water level condition by breaking the connection

between the water level probe and the sensing

circuitry. To test the low water level circuitry,

depress the test switch for 3 seconds. The unit

should fault resulting in the red fault light blinking

and the LED display showing LOW WATER

LEVEL.

Note:

Only water level circuitry is tested during the

above test. To determine if the probe is

functioning properly, the water level must be

reduced below the level of the probe.

To reset the unit, depress the water level reset

switch, the annunciator clear button, and if

necessary, the reset button on the combustion

safeguard.

3.8 ON/OFF SWITCH

The ON/OFF switch is located on the right side

of the control panel above the temperature

controller (see Fig. 3.1). It is part of the start

string and must be in the ON position to enable

the unit to fire. When the switch is in the ON

position and illuminated, it is indicating that the

start limit string, consisting of water temperature,

gas pressure, water level, and the interlock is

satisfied, and that the alarm relay is not

activated. The unit at this point is in standby

mode and ready to run.

Figure 3.10

Water Level Test and Reset Switch Locations

3.9 STARTING SEQUENCE

When the unit is in the standby mode, and there

is a demand for hot water, the following will

occur:

1. Upon demand the temperature controller’s

ON status indicator will light.

2. The combustion safeguard’s PILOT LED

lights and the blower contactor energizes,

starting the blower.

3. The system next checks for proof of closure

from the safety shut-off valve, (see Fig.

3.11), and the air fuel valve rotates open

engaging the air /fuel valve open switch (see

Fig. 3.12).

4. The LCD display shows PURGE INTLK

OPEN until the above conditions are met.

Once met the LCD display will show LOW

AIR FLOW.

5. The blower proof switch closes, (See Fig.

3.13), and the LCD display will show

PURGING.

6. Closure of the blower proof switch signals

the combustion safeguard to begin its 7-

second purge cycle.