Section 6-safety device testing procedures, Figure 6.1, 1/8” pipe plug position for manometer installation – AERCO KC1000 Boiler equipped with Mod-Box Controller User Manual

Page 34: Safety device testing

SAFETY DEVICE TESTING

29

SECTION 6-SAFETY DEVICE TESTING PROCEDURES

6.1 TESTING OF SAFETY DEVICES

Periodic testing of all controls and safety devices

is required to insure that they are operating as

designed. Precautions must be taken while tests

are being performed to protect against bodily

injury and property damage.

Systematic and thorough testing of the operating

and safety controls should be performed on a

scheduled basis, or whenever a control

component has been serviced or replaced. All

testing must conform to local jurisdictions or

codes such as ASME CSD-1.

NOTE:

MANUAL and AUTO modes are required to

perform the following tests. For a complete

explanation of these modes, see Section 3.

NOTE:

It will be necessary to remove the sheet

metal covers and cap from the unit to

perform the following tests.

WARNING!

THIS IS A 120-VOLT AC COMBUSTION

SAFEGUARD SYSTEM. POWER MUST

BE REMOVED PRIOR TO PERFORMING

WIRE REMOVAL OR OTHER TESTING

PROCEDURES THAT CAN RESULT IN

ELECTRICAL SHOCK.

6.2 GAS PRESSURE FAULT TEST

1. Shut off the gas supply to the unit.

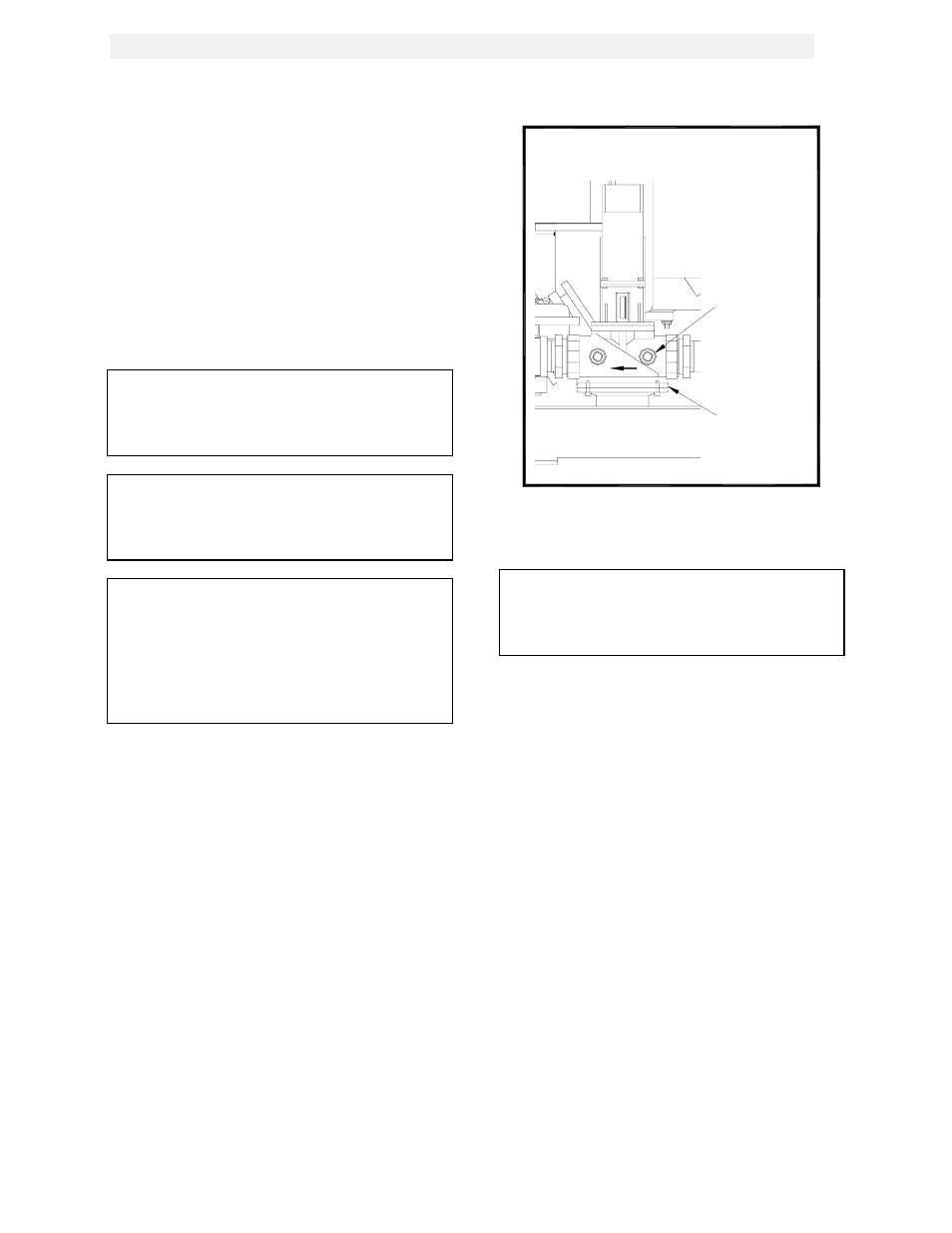

2. Install a 0-16” W.C. manometer in the gas

pipe assembly below the low gas pressure

switch. (See Fig. 6.1)

3. Open the gas supply to the unit and reset

the low gas switch.

4. Start the unit.

5. Slowly close the manual gas supply valve

while monitoring the gas pressure. The unit

should fault and shutdown on “LOW GAS

PRESSURE” when the manometer indicates

approximately 6.5” W.C.

6. Open the gas supply to the unit.

7. The unit should not start until the reset

button on gas pressure switch is depressed.

1/4" NPT PLUG

(INSTALL

MANOMETER

HERE)

SSOV

Figure 6.1

1/8” Pipe Plug Position for Manometer

installation

NOTE:

After faulting the unit, the fault message will

be displayed and the fault indicator light will

flash until the CLEAR button is pressed.

6.3 LOW WATER LEVEL FAULT TEST

1. Place the ON/OFF switch in the OFF

position.

2. Close shut-off valves in the supply and

return piping to the unit.

3. Open the drain valve on the unit.

4. Allow air flow into the unit by either opening

the relief valve or by removing the 1/4” plug

in the top of the unit.

5. The LOW WATER LEVEL message will be

displayed and the fault LED will flash after

the water level has gone below the level of

the probe.

6. The ON-OFF switch should not illuminate

when placed in the ON position and the unit

should not start.

7. Close the drain and pressure relief valve or

reinstall the plug in the top of the unit if

removed.